Solvent recovery systems for battery electrode manufacturing

Efficiently recover and purify solvents in battery electrode manufacturing with systems that ensure compliance with emissions standards while significantly reducing operational costs through a closed-loop process.

Recovers and Purifies NMP Solvent Efficiently

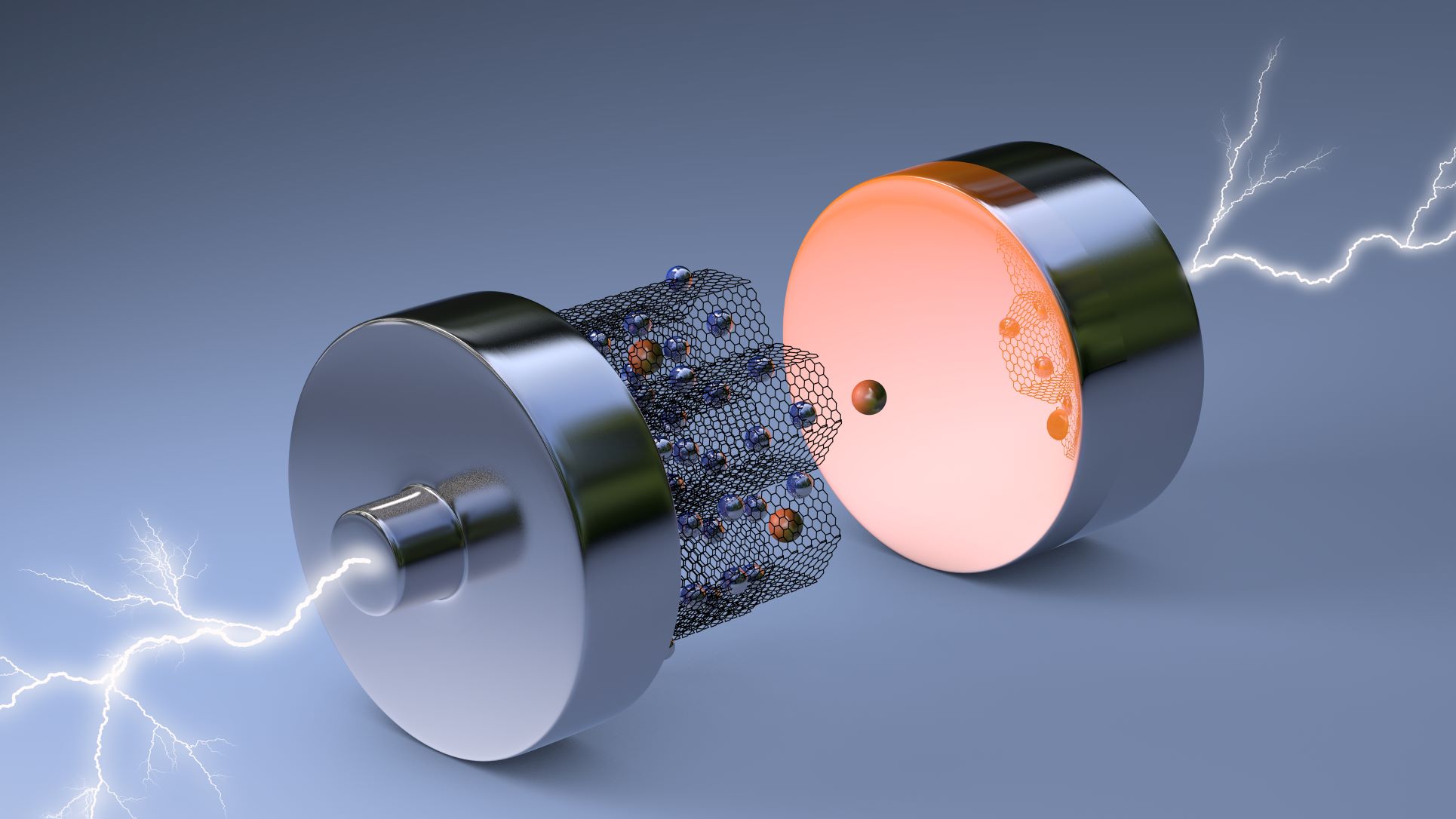

The Solvent Recovery System from Dürr excels in recovering and purifying NMP solvent for battery electrode manufacturing. It operates on a closed-loop principle, capturing exhaust air from dryers, precooling it, and condensing solvent with chilled water. This system is vital for producing electronic-grade solvents with applications in lithium-ion battery and electrode slurry production. Configured for both small-scale labs and industrial setups, it offers flexible throughput solutions—carbon beds for limited operations and condensers with scrubbers for large-scale needs. Integration is seamless, featuring energy-efficient heat exchangers that optimize air temperature within the process cycle. The system is crafted from durable, corrosion-resistant materials, ensuring compatibility with various chemicals. Dürr’s solution not only complies with stringent global emissions standards but also promises rapid ROI by minimizing fresh NMP purchases. Tailored engineering support facilitates customization, from material options to automation features, to meet your specific production requirements.

Benefits

- Ensures compliance with strict emissions standards, reducing regulatory risks.

- Lowers operating costs by recycling and purifying NMP solvent onsite.

- Enhances production efficiency through continuous, closed-loop operation.

- Minimizes solvent loss, contributing to sustainable manufacturing practices.

- Scalable configurations adapt to both small and large-scale production demands.

- Applications

- Batteries, Coating materials

- End products

- Battery electrodes, Lithium-ion batteries, Purified nmp solvent, Electrode slurry, Coated electrode materials, Nmp solvent

- Steps before

- Raw Material Handling, Slurry Mixing, Fluid Delivery, Web Handling, Coating, Drying

- Steps after

- Calendering, Slitting

- Input ingredients

- raw materials, slurry, fluid, exhaust air stream, NMP solvent, air infiltration, dryer exhaust

- Output ingredients

- electronic-grade solvents, purified solvents, recovered solvents, dehydrated solvents, make-up air, discharged air

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- Solvent Recovery Efficiency

- High-efficiency

- Compliance

- Global and Local Emissions Standards

- Solvent Purity Level

- Electronic-grade

- System Type

- Closed-loop

- NMP Recovery Cycle

- Short ROI Cycle

- Heat Exchange Process

- Pre-cooling and Reheating

- Solvent Reuse Option

- Onsite Distillation

- Condensation Type

- Chilled Water

- Slip-stream Handling

- Water Scrubber or Concentrator

- Carbon Bed Requirement

- Optional for Low Emissions

- Integration

- With Dryer Air Stream

- Solvent recovery method

- Chilled water condensation

- Process type

- Closed-loop system

- Automation level

- PLC / SCADA

- Solvent purification system

- On-site dehydration/distillation

- Emissions control

- Condenser, concentrator, scrubber, carbon bed

- Heat exchange process

- Pre-cooling and reheating of exhaust air

- Exhaust air treatment

- Water scrubber or concentrator

- Solvent reuse

- Onsite distillation system

- Corrosive resistance (e.g. acids)

- NMP resistant materials

- Cleanability

- Capable of solvent removal and purification

- Coating Line Configuration

- Turnkey system

- Cooling Method

- Pre-cooled heat exchange with dryer exhaust

- Heating Method

- Reheated via heat exchange with dryer exhaust

- Exhaust System

- Closed-loop, chilled water condensation

- Solvent Recovery Configuration

- Condenser with optional concentrator/scrubber

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Seamless with existing systems

- Solvent recovery system configuration

- Customizable

- System scalability

- Scalable for different production sizes

- Heat exchange options

- Pre-cooling and reheating capabilities