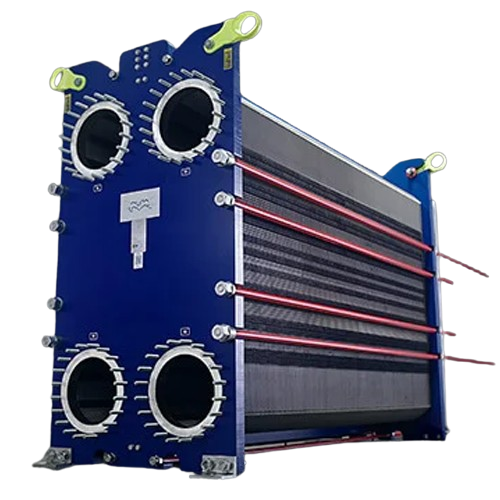

Gasketed plate-and-frame heat exchangers for industrial applications

Optimize your production with precise thermal management, ensuring efficient heat transfer for versatile applications in challenging environments.

Transfers Heat for Efficient Thermal Management

The Gasketed Plate-and-Frame Heat Exchanger T21 from Alfa Laval is designed to maximize heat transfer efficiency across various industries including food, beverage, pharmaceutical, and energy. This exchanger leverages corrugated plate technology to optimize thermal management through large surface areas, enabling effective handling of aggressive fluids and fibrous media. Capable of supporting processes such as heating, cooling, condensation, and evaporation, it is instrumental in producing pasteurized milk, pharmaceutical ingredients, and high-fructose corn syrup among others.

This equipment demonstrates outstanding thermal efficiency with a compact design that minimizes space requirements and simplifies servicing. Its modular structure allows flexible integration into existing production lines, offering easy adaptation to changing duty requirements. Energy-efficient operation is a hallmark of the T21, reducing energy consumption through close temperature approach technology, which minimizes waste and emissions.

Constructed with robust materials tailored for aggressive environments, the T21 offers options in stainless steel and specialty alloys for superior corrosion resistance. It meets stringent compliance standards for hygienic applications, supporting GMP and FDA certifications, and is equipped with a Clean-In-Place (CIP) system to facilitate maintenance while minimizing downtime. Custom engineering support is available to tailor design features such as plate configurations and gasket materials, ensuring optimal performance for specific operational demands.

Benefits

- Increases energy efficiency by reducing waste heat loss, lowering operational costs.

- Adapts easily to changing production demands, enhancing process flexibility.

- Minimizes maintenance downtime with integrated CIP system, ensuring continuous operation.

- Provides a sustainable solution with low environmental footprint, supporting carbon reduction goals.

- Ensures product integrity in aggressive environments with robust, corrosion-resistant materials.

- Applications

- Heat recovery, Food, Beverage, Refrigeration, Fibrous media, Heating, Cooling, Pharma, Aggressive fluids, Evaporation, Condensation

- End products

- Carbonated beverages, Vaccines, Lyophilized pharmaceuticals, Wine, Cellulose pulp, Propylene glycol, Ammonia coolant, Fruit juice concentrate, Recycled paper slurry, Pasteurized milk, Essential oils, High-fructose corn syrup, Chemical solvents, Yogurt, Chlorinated water, Beer, Pharmaceuticals

- Steps before

- Heating, Cooling, Fluid Mixing, Pre-filtration

- Steps after

- Condensation, Evaporation, Packaging, Refrigeration

- Input ingredients

- gas, liquid, fluids, heat sensitive media, viscous media, aggressive fluids, difficult fluids, fibrous media, fluids containing fibers, coarse particles, corrosive materials

- Output ingredients

- heated gas, cooled gas, heated liquid, cooled liquid, clean fluids, hotter fluid, colder fluid

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Thermal Efficiency

- Highest efficiency

- Temperature Approach

- Close temperature approach

- Compact Design

- Space saving

- Adaptability

- Easy to adapt to duty requirements

- Heat Transfer Optimization

- High turbulence and self-cleaning

- Pressure Range

- Extended in semi-welded plates

- Corrosion Resistance

- Graphite non-metallic plates

- Leakage Prevention

- Double-wall gasketed plates

- Handling of Aggressive Fluids

- Semi-welded plates

- Flexibility

- Capacity modification by adding/removing plates

- Flow Patterns

- Counter-current and Co-current

- Gasket and Plate Design

- Optimized seal and performance

- Plate Patterns

- Herringbone and corrugation

- Working mechanism

- Corrugated plates for heat transfer

- Heat transfer optimization

- High efficiency, large surfaces

- Turbulence flow

- Helix-like flow in plates

- Compact design

- Space-saving and easy maintenance

- Adaptability

- Flexible to duty changes

- Energy efficiency

- Low environmental footprint

- Automation level

- Manual / PLC-controlled

- Corrosion resistance

- Stress, wear, corrosion resistant

- Cleaning method

- Easy to clean and service

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Easy to clean

- Compact footprint

- Space saving

- Plate type

- Gasketed, semi-welded, wide-gap, double-wall

- Corrugation pattern

- Herringbone pattern

- Frame type

- Conventional frame plate and pressure plate

- Modularity

- Easy to add or remove plates

- Control Panel Type

- PLC-controlled for automation

- Compact footprint

- Compact units - space saving

- Control panel type

- Customizable integration

- Discharge method

- Flexible - easy to adapt to changed duty requirements