Monomer recovery unit

Effectively recover valuable monomers while ensuring high purity and low operating pressures, ideal for maximizing efficiency in your chemical processing lines.

Recovers and Purifies Monomers from Hydrocarbons and Nitrogen

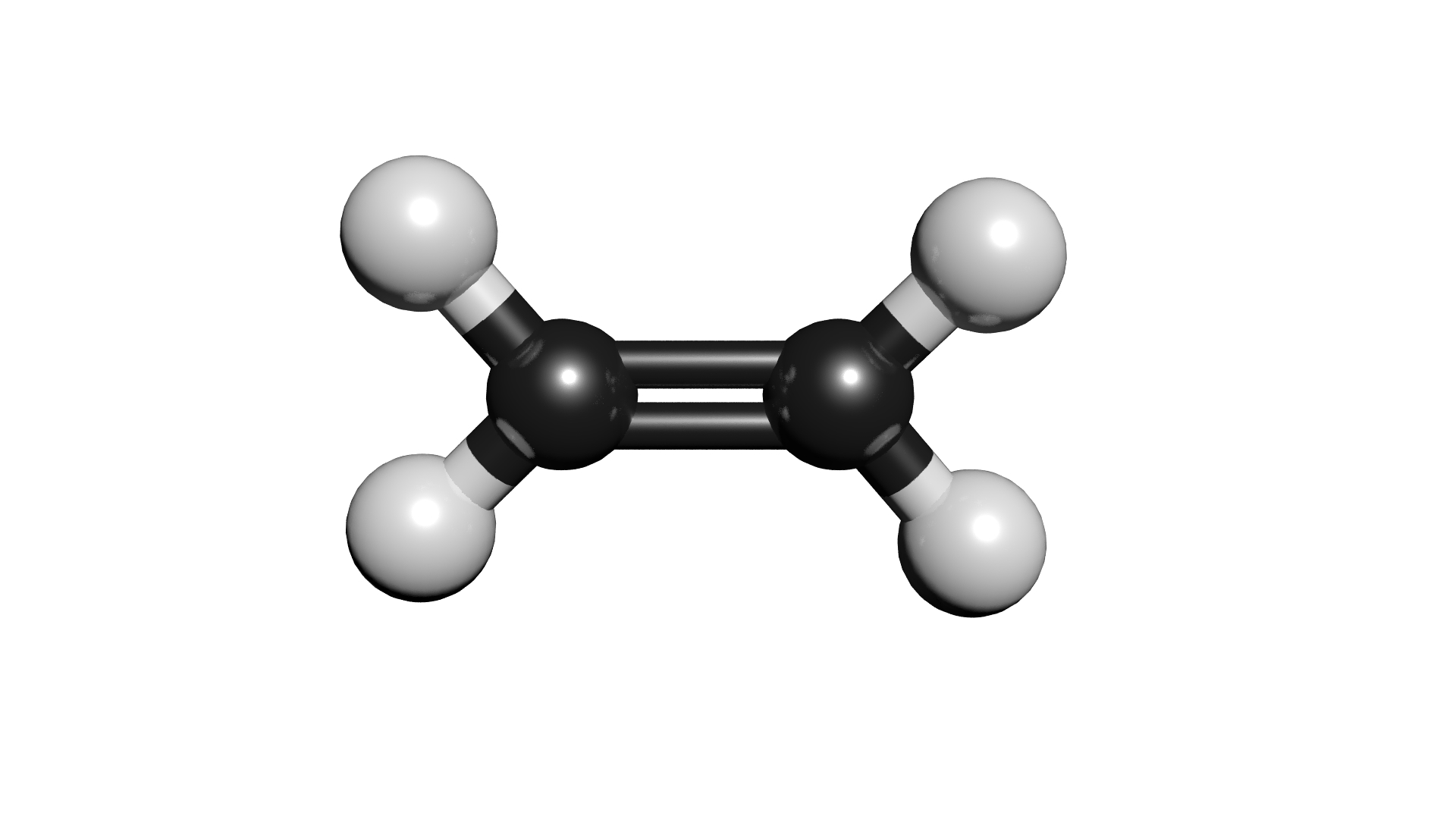

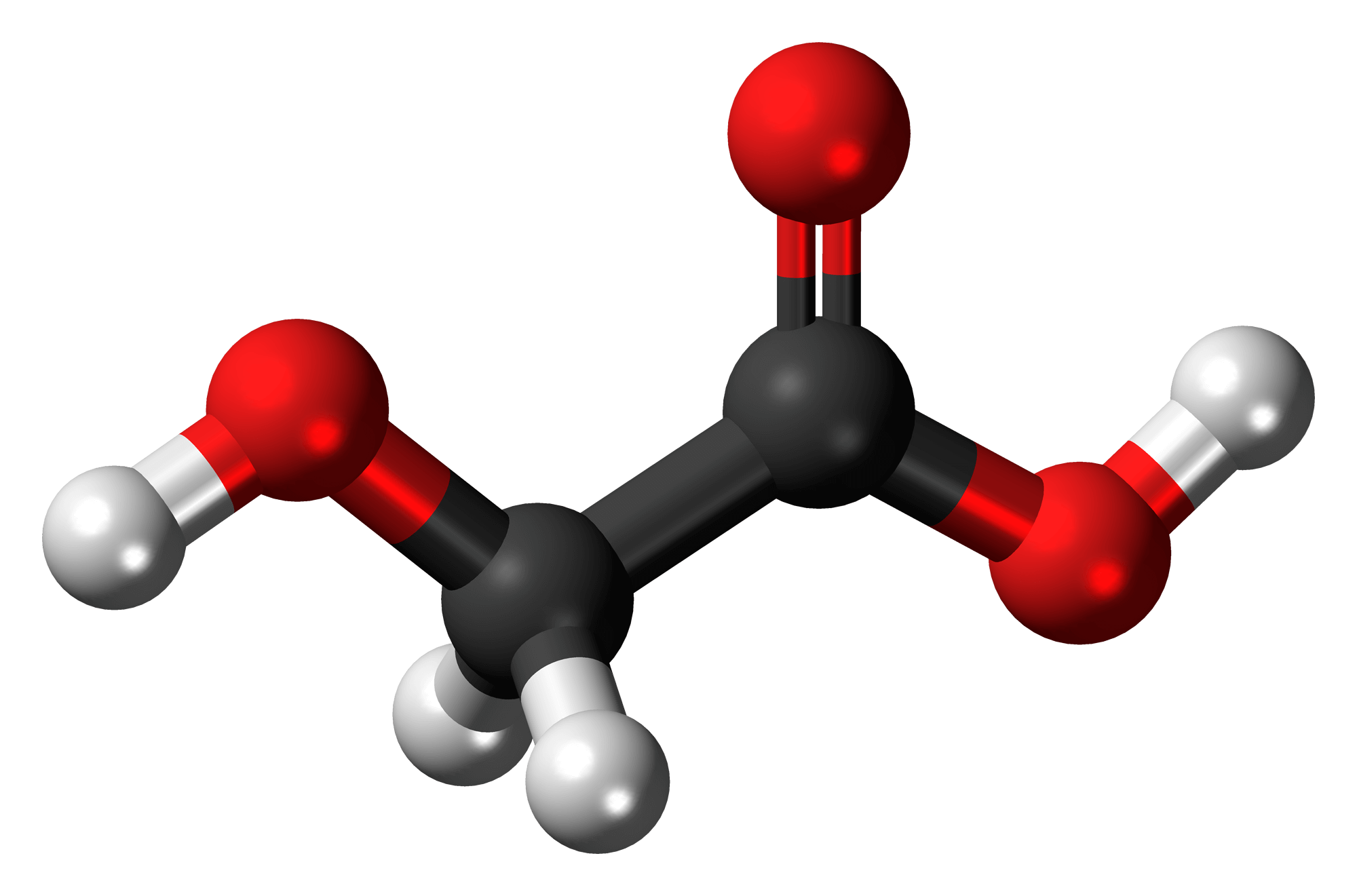

The BORSIG Monomer Recovery Unit leverages the cutting-edge capabilities of BORSIG Membrane Technology GmbH to streamline and enhance the separation of hydrocarbons and nitrogen in various industrial applications. This specialized system efficiently recovers monomers like ethylene and propylene, vital for manufacturing polyethylene and polypropylene, through a process combining membrane separation with compression, condensation, and heating stages. Ideal for sectors such as petrochemical and industrial gas production, the unit’s modular design allows easy integration into existing plants and offers flexibility for handling multiple component streams.

Operating at moderate pressures and temperatures, the system ensures safe, reliable, and low-maintenance performance. Its package unit design enables quick installation and seamless adaptation to specific plant conditions and local regulations. The membrane technology optimizes nitrogen purification, while the hydrocarbon-enriched permeate stream supports further processing or improved condensation. The BORSIG Monomer Recovery Unit is a robust solution for industries seeking to enhance recovery rates and achieve high product purities, contributing to more sustainable and efficient production processes.

Benefits

- Ensures high recovery rates and product purities, enhancing production efficiency.

- Safe operation with reliable, low-maintenance performance reduces operational costs.

- Modular design enables quick integration and adaptation to existing systems.

- Operates at moderate pressures and temperatures, contributing to energy savings.

- Flexible system accommodates multiple components, meeting diverse production needs.

- Applications

- Propylene, Hydrocarbons, Monomers, Ethylene, Nitrogen

- End products

- Polyethylene, Polypropylene, Nitrogen purification, Ethylene glycol, Hydrocarbon fuels, Styrene monomer

- Steps before

- Compression, Condensation, Heating

- Steps after

- Purification, Recycling, Distribution

- Input ingredients

- nitrogen, hydrocarbons

- Output ingredients

- hydrocarbon enriched permeate, purified nitrogen

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Recovery Rate

- Highest recovery rates

- Product Purity

- Highest product purities

- Operating Pressure

- Moderate pressures applied

- Operating Temperature

- Moderate temperatures applied

- Design

- Modular design

- Adaptability

- Adaptation to existing plants

- Modular design

- Adaptable to plant conditions

- System flexibility

- Handles multiple components

- Batch vs. continuous operation

- Suitable for inline continuous

- Safety operation

- High reliability, low maintenance

- Automation level

- Manual / Integrated Automation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Modular Design

- Flexible system

- Multiple Components Handling

- Flexible system

- Modular design

- Yes

- Footprint

- Compact

- Adaptation to existing plants

- Feasible

- Control panel type

- Package unit design

- Flexible system

- Multiple components handling

- Modular design

- To meet specific plant conditions and local regulations

- Package unit design

- Quick installation and easy implementation