Manure treatment micro-filter for slurries

Enhance water reuse and nutrient recovery by transforming slurry into micro-screened liquids, ideal for fertigation and biogas processes, while optimizing pretreatment efficiency in your water and wastewater management systems.

Micro-filters Slurries for Liquid Reuse

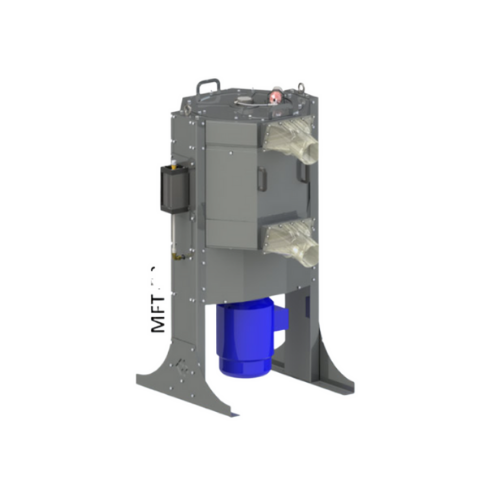

The SEPCOM Micro-filter MFT, a product of WAMGROUP, offers advanced micro-filtration solutions for slurry treatment in environmental and wastewater applications. This equipment features a sturdy stainless-steel design with a long-life screen basket and impeller, ensuring durability and reliability. It efficiently separates micro-screened liquids from slurry through a continuous operation that integrates seamlessly with existing pre-treatment processes. Used extensively in livestock breeding, biogas plant, and municipal wastewater treatment, it maximizes the reuse of filtered liquid for fertigation and anaerobic digester dilution. With a maximum throughput of 20 m³/h, it offers low operating costs and easy maintenance, making it an ideal choice for operators seeking sustainable and cost-effective filtration solutions. The SEPCOM Micro-filter MFT’s flexibility with screen basket slot sizes and optional integration with a microfiltration plant underscores its adaptability to diverse operational needs.

Benefits

- Enhances liquid reuse efficiency, supporting environmental sustainability.

- Minimizes operational costs with low maintenance requirements.

- Improves separation precision for better downstream processing.

- Maximizes throughput with robust stainless-steel construction.

- Facilitates digestion and fertigation processes with versatile filtered outputs.

- Applications

- Manure treatment, Sludge treatment, Livestock breeding, Environmental technology, Biogas plant equipment, Municipal waste water treatment

- End products

- Treated manure effluent for agricultural use, Sludge dewatering effluent, Cleaned municipal wastewater, Micro-screened liquid for fertigation, Micro-filtered biogas slurry, Purified water for reuse, Dilution liquid for anaerobic digesters

- Steps before

- Separation Process, Digestate Separation, Industrial Wastewater Separation

- Steps after

- Fertigation, Biogas Plant Feeding, Anaerobic Digestion

- Input ingredients

- slurries, digestate, industrial wastewater, pre-separated liquid

- Output ingredients

- micro-screened sludge, micro-screened liquid, solid phase, filtered liquid for fertigation

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Hydraulic throughput

- Max 20 m³/h

- Screen basket slot size

- 0.025 mm to 0.050 mm

- Automation level

- PLC / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- Low operating costs

- Cleaning method

- Manual

- Micro-filtration

- High filtration efficiency

- Micro-filtering system use

- Pretreatment upstream of a centrifuge

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Micro-filtered liquid application

- Fertigation/biogas

- Basket slot size

- 0.025 mm to 0.050 mm

- Material introduced point

- Lower part of the machine

- Discharge method

- Solid phase expelled through the top

- Max hydraulic throughput

- 20 m3/h

- Screen material

- Stainless steel

- Impeller material

- Complete stainless steel

- Control panel type

- Stainless-steel with level sensors

- Screen basket slot size

- 0.025 mm to 0.050 mm

- Microfiltration plant options

- Including stainless-steel storage tank, feeding pump, level sensors, and control panel