Co2 recovery system for breweries

Unlock the full potential of fermentation by capturing and purifying CO2 for immediate reuse or sale, enabling significant cost savings and contributing to a greener production process.

Captures and Purifies Fermentation CO2

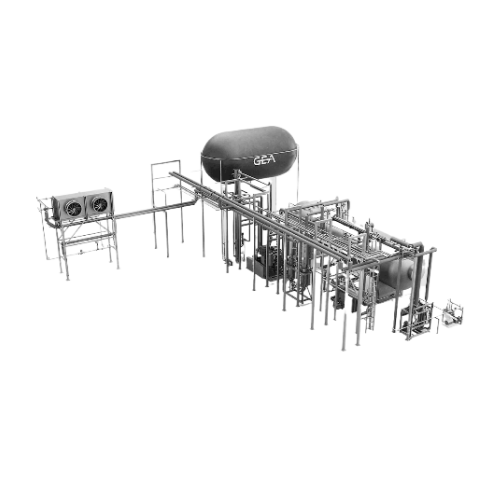

The GEA CO2 Recovery System is a solution engineered for breweries and beverage manufacturers to efficiently capture and purify CO2 generated during fermentation. This system is distinct in its ability to achieve 99.998% food-grade CO2 purity, crucial for carbonating beverages like beer, sparkling wines, and sodas, or manufacturing dry ice. With a capacity of up to 5,000 kg/h, it handles both large-scale and continuous operations, integrating seamlessly with existing energy systems to optimize efficiency. The process involves capturing raw gas, scrubbing, compression, purification, drying, and liquefaction, ensuring minimal waste and high resource recovery. Fully automated, the system enhances operational reliability and reduces manual intervention, thus saving costs and supporting environmental sustainability. Its robust design, featuring components like gas scrubbers and storage tanks, offers flexibility and durability. GEA also provides customization and engineering support to tailor the system for your specific fermentation process, ensuring seamless integration into new or existing plant infrastructure.

Benefits

- Reduces operational costs by producing high-purity CO2, eliminating reliance on external suppliers.

- Enhances sustainability by capturing and reusing CO2, cutting emissions and carbon footprint.

- Increases production efficiency through fully automated, continuous operation.

- Offers rapid ROI, potentially self-financing within 1.5 to 4 years.

- Integrates seamlessly with existing brewery energy systems, optimizing resource use and minimizing waste.

- Applications

- Carbonated beverages, Sparkling wines, Brewing, Dry ice manufacturing, Food and beverage

- End products

- Tonic water, Champagne, Granita, Lemon-lime soda, Ginger ale, Prosecco, Sparkling water, Cola, Carbonated fruit juice, Beer

- Steps before

- Fermentation, Gas capture, Gas scrubbing

- Steps after

- Storage of liquid CO2, Carbonation, Manufacturing of dry ice

- Input ingredients

- raw gas, fermenting microorganisms, gas scrubbers

- Output ingredients

- pure CO2, food-grade CO2, liquid CO2, condensed CO2

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- CO2 Purity

- 99.998% food-grade

- Capacity

- Up to 5, 000 kg/h

- Automation

- Fully automated

- Emissions

- Lower emissions, reduced carbon footprint

- Plant availability

- Above 95%

- Downtime for servicing

- Kept as low as possible

- Energy Efficiency

- Waste heat recovery

- Oxygen content reduction

- Less than 5 ppm

- System Compatibility

- Customizable to existing energy supply systems

- Automation level

- Fully automated

- Batch vs. continuous operation

- Batch / Continuous adjustable

- Cleaning method

- Low maintenance requirements

- Energy efficiency

- Heat recovery

- Purity level

- 99.998% food-grade CO2

- Machine Footprint

- Customizable

- CO2 Recovery Capacity

- Up to 5, 000 kg/h

- System Integration

- Seamless with existing energy supply systems

- Component Material

- Durable, high-performing materials

- Maintenance

- Low downtime, above 95% availability

- Automation

- Fully automated

- Integration possibilities

- Seamless integration into existing systems

- Capacity customization

- Up to 5, 000 kg/h

- System configuration

- Customizable based on fermentation process

- Energy optimization

- Integration with existing energy supply

- Component selection

- Durable and high-performing components