Multi-effect water distiller for pharmaceutical and biological applications

Achieve unmatched water purity for sterile injectables and biologic drugs with continuous, multi-effect distillation that ensures less than 0.01 EU/ml endotoxin levels, optimized for seamless integration into biopharmaceutical manufacturing.

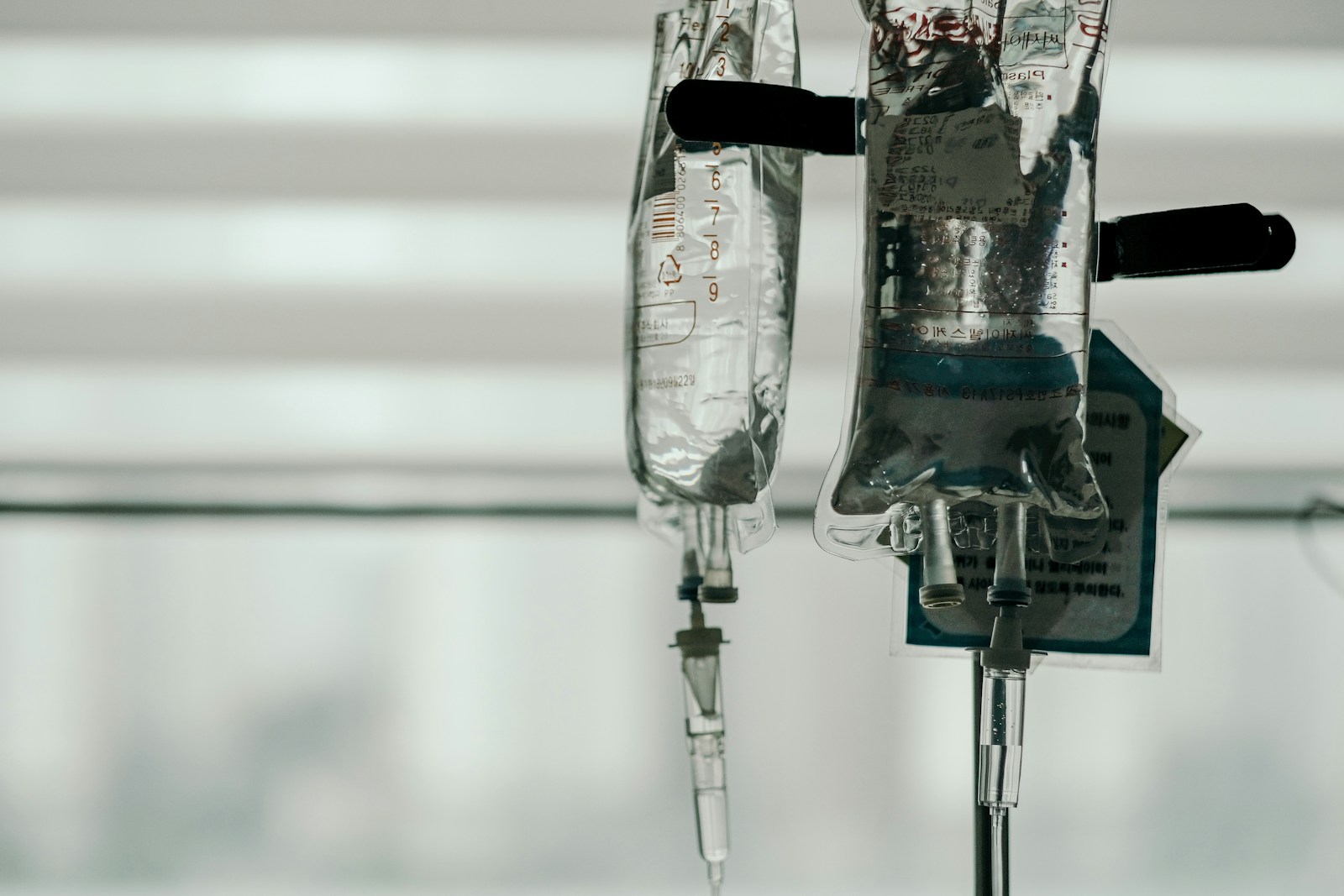

Produces High-Purity Water for Injection

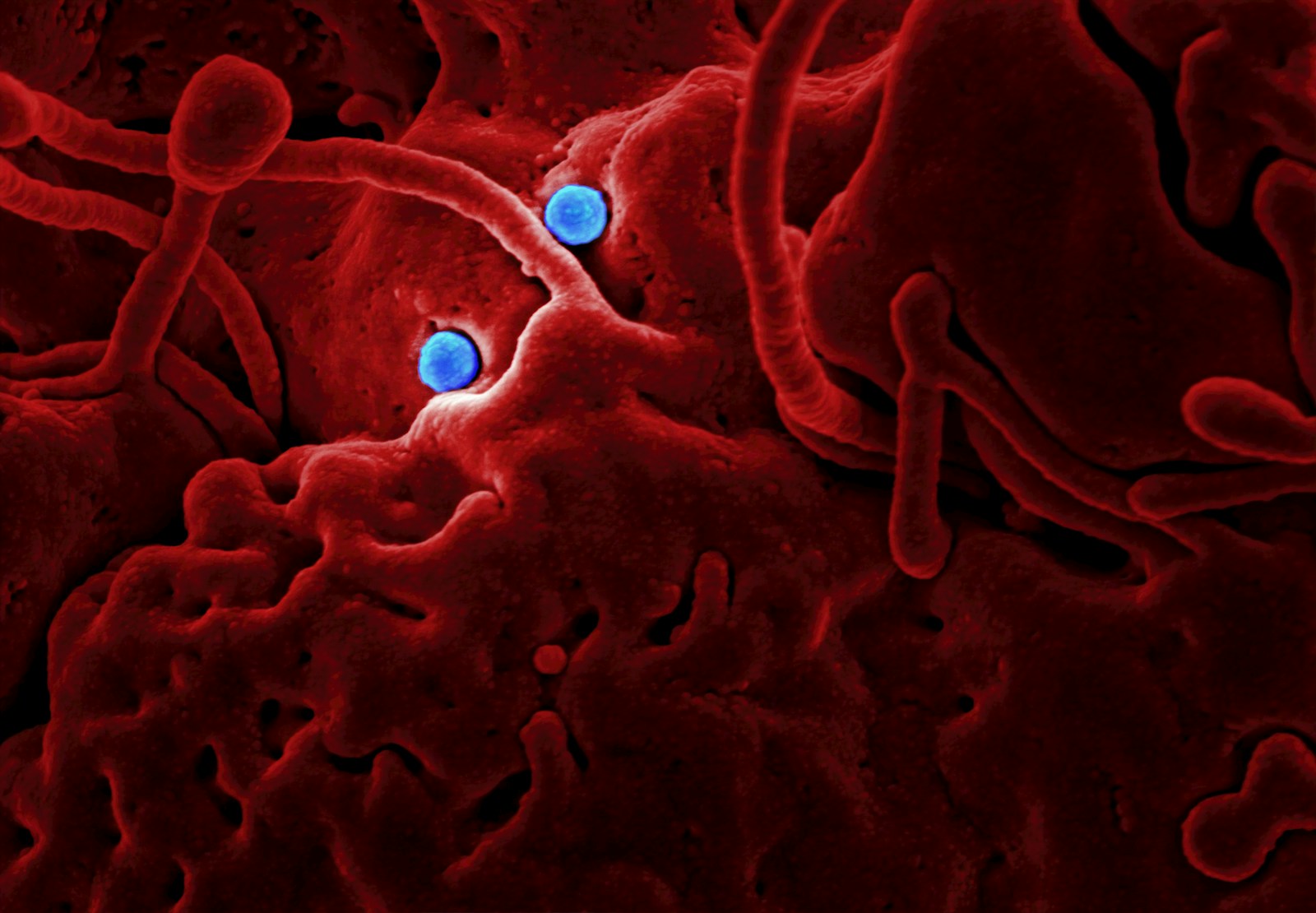

The Finn-Aqua TC Series from Steris is a multi-effect water distiller designed specifically for pharmaceutical and biopharmaceutical applications. It utilizes a three-stage separation process to ensure the production of high-quality water for injection (WFI) that surpasses industry standards in the USA and EU. The TC series addresses common challenges in achieving ultra-pure water by implementing continuous non-condensable gas removal technology, meeting HTM 2010 and EN285 requirements. Operated via a Siemens S7 series control system, this distiller offers user-friendly automation for seamless integration into your production line. The equipment is particularly suited for manufacturing sterile injectables, biologic drugs, vaccines, and other high-purity liquid products. With robust construction for long-lasting performance, the distiller is compliant with cGMP guidelines, essential for maintaining regulatory standards.

Benefits

- Ensures ultra-high purity water with endotoxin levels below 0.01 EU/ml, essential for sensitive pharmaceutical applications.

- Streamlines operations through user-friendly Siemens S7 control system, minimizing training and human error.

- Delivers consistent quality with continuous, automated processes, reducing production interruptions.

- Complies with global standards like cGMP, HTM 2010, and EN285, facilitating international market access.

- Enhances process efficiency with multi-effect distillation, optimizing heat usage and lowering operational costs.

- Applications

- Biological industry, Biopharmaceuticals, Pharmaceutical industry

- End products

- Biologic drugs, Intravenous fluids, Vaccines, Sterile injectables, Pharmaceutical tablets, Biopharmaceutical intermediates, Monoclonal antibodies, Cell culture media, Ophthalmic solutions, Therapeutic proteins

- Steps before

- Purification

- Steps after

- Sterilization

- Input ingredients

- steam, feed water

- Output ingredients

- Water for Injection (WFI), Purified water, non-condensable gases, endotoxin-free water

- Market info

- Austar is known for specializing in the design and manufacture of engineered-to-order industrial equipment, particularly in the pharmaceutical and biotechnology sectors, offering solutions that focus on quality, innovation, and meeting specific customer requirements.

- Compliance

- cGMP

- Endotoxin level

- Less than 0.01 EU/ml

- Control system

- Siemens S7 series

- Distillation type

- Multi-effect

- Gas removal technology

- Continuous non-condensable gas removal

- Heat source

- Steam

- Output quality

- Meets HTM 2010 and EN285

- Separation process

- Three-stage

- Multi-effect distillation

- Yes

- Endotoxin level

- Less than 0.01 EU/ml

- Non-condensable gas removal

- Continuous

- Automation level

- Siemens S7 PLC-controlled

- Manual vs. automated operation

- Automated

- Heat source

- Steam

- Water for Injection quality

- Pharmaceutical grade

- Control panel type

- Siemens S7 series

- Control panel type

- Siemens S7 series control system