High-throughput surface plasmon resonance (spr) system

Rapidly achieve high-quality binding kinetics for drug discovery with a cutting-edge system that combines label-free biomolecular interaction analysis capabilities, streamlining the characterization of complex molecular interactions essential for developing therapeutic innovations.

Analyzes Molecular Interactions for Drug Discovery

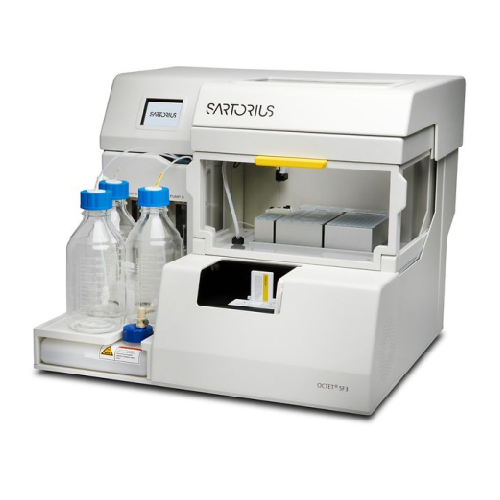

The Octet® SF3 SPR System from Sartorius is a cutting-edge surface plasmon resonance (SPR) platform that streamlines the analysis of molecular interactions crucial for drug discovery and development in pharmaceutical and biotech environments. Distinguished by its unique OneStep® and NeXtStep™ Gradient Injection technologies, it offers exceptional sensitivity for both small and large molecules, drastically reducing analysis time. This system supports high-throughput operations, capable of processing up to 768 samples in a single assay, thanks to its extended unattended run times and optimized fluidics. Ideal for applications in biopharmaceuticals, vaccines, and antibody fragments, the Octet® SF3 SPR system excels in characterizing complex biomolecular interactions, including high-affinity kinetics and site-specific competition. Engineered for continuous operation and automated integration, it integrates seamlessly into laboratory workflows, delivering precise and reproducible data essential for biomanufacturing and research applications. Its robust design minimizes maintenance while supporting sample recovery, allowing reanalysis across a wide range of conditions.

Benefits

- Accelerates research timelines by processing up to 768 samples in a single assay.

- Enhances data accuracy with unique injection technologies for precise kinetic and affinity measurements.

- Minimizes operational costs with low maintenance and high durability design.

- Facilitates comprehensive analysis with sample recovery capabilities for reuse.

- Supports diverse assay conditions with automated in-line buffer degassing and temperature variation options.

- Applications

- Biologics, Drug discovery, Therapeutics, Vaccines, Small molecules, Antibody screening, Biopharmaceuticals, Molecular interactions, Antibody fragments, Protein analysis, Fragment-based drug discovery, Whole cell biologics

- End products

- Oncolytic viruses, Small molecule drugs, Car-t cell therapies, Fragment antibodies, Peptide drugs, Monoclonal antibodies, Biosimilars, Adeno-associated viruses (aav), Covid-19 vaccines, Engineered protein drugs, Therapeutic antibodies, Mrna vaccines, Influenza vaccines

- Steps before

- Sample Preparation, Buffer Preparation, Concentration Dilution Series Preparation

- Steps after

- Data Analysis, Sample Recovery, Thermodynamic and Physiological Measurements

- Input ingredients

- analyte, buffer, competitor molecule

- Output ingredients

- binding kinetics data, affinity data, thermodynamic measurements, physiological measurements, kinetic profiles, site-specific competition data

- Market info

- Sartorius AG is renowned for manufacturing high-precision laboratory and bioprocess equipment. They specialize in filtration, fermentation, and cell cultivation systems, known for their innovation and reliability in the pharmaceutical and biotech industries.

- Sensitivity

- Small and large molecules

- Baseline Noise

- Low

- Drift

- Low

- Injection Volume

- Large

- Injection Technology

- OneStep® and NeXtStep™

- Automation

- High-throughput

- Sample Capacity

- Up to 768 samples per assay

- Unattended Run Time

- More than 72 hours

- Fluidics System

- Optimized, low maintenance

- Buffer Volume

- Up to three one-liter bottles

- Buffer Lines

- Independently functioning

- Sample Recovery

- Re-use capability

- Temperature Range

- Wide range for physiological studies

- Syringe Volume

- 700 µl

- Degassing

- In-line buffer degassing

- High-Throughput Operation

- 768 samples in a single assay

- Automation Level

- High-throughput, low maintenance

- CIP/SIP

- Optimized cleaning protocols

- Injection Technology

- OneStep® and NeXtStep™ Gradient Injections

- Sample Recovery

- Predefined Sample Recovery Injection

- Fluidics System

- Optimized to minimize blockage

- Buffer System

- Independent buffer lines

- Unattended Run Time

- More than 72 hours

- Temperature Study Range

- Wide range for physiological assessments

- Injection Volume

- Large

- Baseline Noise and Drift

- Low

- Binding Kinetics Data Generation

- Fast and accurate

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³

- 21 CFR Part 11 Compliance

- Yes

- Footprint

- Compact design

- Injection Technology

- OneStep®, NeXtStep™ Gradient Injection

- Fluidic System

- Optimized for minimal blockage

- Sensor Chip Selection

- Multiple options for accuracy and reproducibility

- Sample Capacity

- Up to 768 samples per run

- Temperature Range

- Physiological temperatures

- Buffer Capacity

- Three-liter total capacity

- Control Panel

- User-friendly interface

- Injection Technology

- OneStep® / NeXtStep™

- Injection Formats

- Single Cycle / Multi-Cycle

- Sample Recovery Injection

- Predefined Recovery Protocols

- Buffer Lines

- Independent Function / Dual Running Buffers

- Water Line

- Dedicated Line for Minimizing Precipitation

- Fluidic System

- Optimized for Blockage Prevention

- Temperature Range

- Wide Range Including Physiological Conditions

- Syringe Volume

- 700 µl for Accurate Calculations

- Sample Layout

- High-Throughput Layout Design