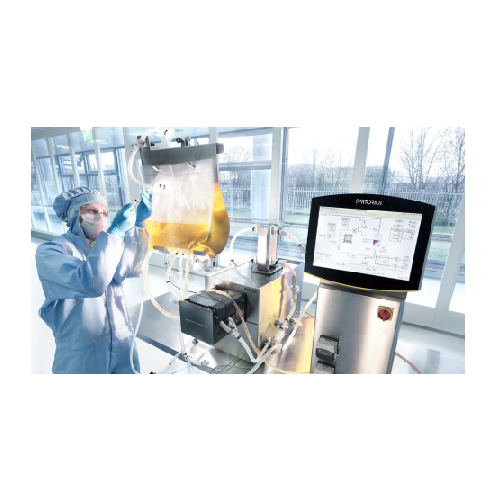

Tangential flow filtration system for cell harvesting

Optimize your biopharmaceutical production by integrating a versatile filtration system that ensures efficient separation and purification, crucial for maintaining high product quality in sensitive processes like gene therapy and monoclonal antibody production.

Filters and Purifies Biopharmaceutical Products

Sartorius offers a comprehensive range of process filtration systems tailored for the biopharmaceutical industry, renowned for their reliability and precision. Utilizing cutting-edge membrane technology, these systems effectively filter and purify liquids, crucial for applications in producing monoclonal antibodies, vaccines, and gene therapies. Featuring scalable and customizable solutions, Sartorius designs these units to handle various capacities, ensuring seamless integration with existing production lines. Their systems are equipped with advanced PLC controls for automation and monitoring, optimizing energy use and ensuring adherence to stringent GMP and FDA standards. Constructed from high-grade materials, these filtration units offer exceptional resistance to corrosion, making them ideal for challenging pharmaceutical environments. Furthermore, these systems are designed with CIP capabilities to facilitate maintenance and maximize operational efficiency. Sartorius extends comprehensive engineering support and customization options to meet specific processing requirements, ensuring your system aligns perfectly with your production goals.

Benefits

- Enhances product purity and quality, ensuring compliance with regulatory standards.

- Reduces operational costs through energy-efficient design.

- Increases production flexibility with scalable and customizable solutions.

- Minimizes maintenance time with integrated cleaning systems.

- Ensures seamless process integration with advanced automation and control capabilities.

- Applications

- Biologics, Vaccines, Pharmaceutical microbiology, Monoclonal antibodies, Mrna production, Biosimilars, Regenerative medicine, Cell therapy, Cell culture media, Biopharmaceuticals, Gene therapy, Advanced cell systems, Blood and plasma

- End products

- Oncolytic viruses, Car-t cell therapies, Hematopoietic stem cells, Erythropoietin, Aav vector gene therapies, Rituximab, Spike protein mrna vaccines, Platelet-rich plasma (prp) products, Advanced wound care matrices, Gamma globulin, Stem cell-derived dopamine neurons, Herceptin, Insulin glargine, Exosome-based therapeutics

- Steps before

- Sample Preparation, Cell Culture Development, Plasmid DNA Transfection, Cell Banking, Media Filtration, Virus Filtration

- Steps after

- Sterility Testing, Virus Clearance Validation, Product Characterization, Lot Release Testing, Sterilization, Quality Control

- Input ingredients

- cell culture media, bacteria, mycoplasma, viruses, plasmid DNA, media, buffers, transfection reagents

- Output ingredients

- sterilized media, filtered media, safe cell culture products, filtrate, purified media, virus-free products, processed cell culture media

- Market info

- Sartorius AG is renowned for manufacturing high-precision laboratory and bioprocess equipment. They specialize in filtration, fermentation, and cell cultivation systems, known for their innovation and reliability in the pharmaceutical and biotech industries.

- Accuracy

- ±0.5–2%

- Air speed

- 1–20 m/s

- Automation

- PLC-controlled

- Batch size

- 5–100 kg

- Capacity

- 50–2000 kg/h

- Cycle time

- 15–60 min

- Efficiency

- Low kWh/kg

- Feed rate

- 50–1000 kg/h

- Filtration type

- Depth / membrane / crossflow

- Fill weight accuracy

- ±2–5%

- Filling speed

- 10k–150k/hr

- Filling volume

- 1 ml – 5 L

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- up to 10, 000 cP

- Control panel type

- Touchscreen / Button Interface

- Integration possibilities

- SCADA / PLC / DCS Systems

- Footprint

- Compact / Modular Design

- Discharge method

- Automated / Manual

- Automation level

- Fully Automated / Semi-Automated