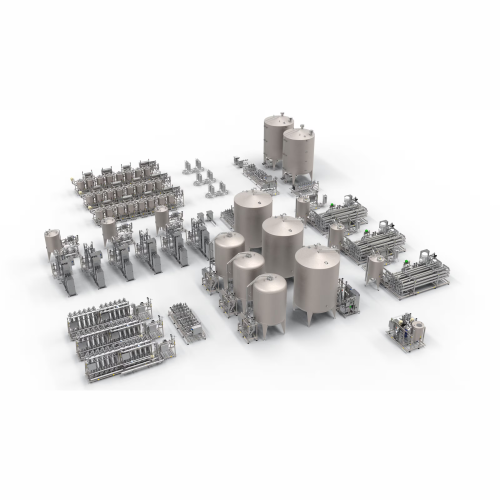

Industrial water treatment system

Ensure your beverage production maintains optimal purity and taste with tailored water treatment solutions that provide precise filtration, remineralization, and deionization, enabling consistent quality in every batch.

Purifies, Remineralizes, and Stabilizes Water for Beverages

The Hydronomic Water Treatment System from Krones is engineered for precision water treatment, ideal for beverage and food production industries. It stands out with its modular design, enabling seamless integration into existing production lines, and offers flexibility with processes like ultrafiltration, reverse osmosis, and ozonisation. Capable of handling between 5 and 120 m³ per hour, this system ensures efficient purification, remineralization, and desalination for diverse applications, such as still water, soft drinks, and brewing. Its stainless steel construction supports complete sanitization, enhancing hygiene and longevity. With advanced automation, it reduces chemical usage and energy consumption, while its comprehensive CIP capabilities simplify maintenance. The system supports customization to meet specific production requirements, backed by Krones’ expert engineering support.

Benefits

- Enhances product quality with precise water purification and remineralization tailored to beverage formulations.

- Lowers operational costs through reduced energy consumption and minimized chemical usage.

- Supports scalability with its modular design, allowing for easy expansion and integration.

- Ensures hygiene and longevity with stainless steel construction and full sanitization capability.

- Reduces downtime and maintenance effort with efficient CIP processes and remote monitoring.

- Applications

- Still table water, Water treatment, Brewing, Juice, Soft drinks, Tea

- End products

- Mineral water, Green tea, Ales, Black tea, Flavored soft drinks, Lagers, Herbal tea, Bottled still water, Citrus juices, Ipas, Electrolyte water, Berry juices, Carbonated sodas

- Steps before

- Raw water sourcing, Initial filtration, Pre-treatment

- Steps after

- Microbiological stabilization, Packaging, Filling

- Input ingredients

- untreated water, brewing water, process water, raw material for soft drinks, juice, tea, fluctuating untreated water, suspended solids, odorants, organics, chlorine, iron, manganese

- Output ingredients

- treated water, deionised water, remineralised water, ultraclean water, ultrafiltrate, desalinated water, microbiologically stabilised water, filtered water

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Water treatment capacity

- 5–120 m³/h

- Filtration performance

- Up to 150 m³/h (UF)

- Rinsing water consumption

- Max. 36 m³/h

- Yield

- Up to 99.9% (UF)

- Yield

- Up to 99.5% (MF/GAC)

- Pore size

- 0.02 µm (UF)

- Cycle time

- Step-by-step CIP sequences

- Material

- Stainless steel construction

- Membrane technology

- Hollow fibres (UF)

- Residual content after desalination

- Less than 3% (RO)

- Automation

- Variable output regulation and automatic yield control (RO)

- Energy efficiency

- Energy-efficient motors and optimally designed pumps and heat exchangers

- Working mechanism

- Microbiological stabilisation

- Integrated steps

- Ozonisation with Krones Ozonomic

- CIP principles

- Sanitised with hot water

- Batch vs. continuous operation

- Variable production quantity

- Automation level

- Fully automated module control

- Flexibility and customisation

- Modular component system

- Cleaning method

- Hot water sanitizing

- Energy efficiency

- Energy-efficient motors

- Minimised waste water

- Sophisticated technology

- Access and serviceability

- Best possible access for operators

- Corrosive resistance (e.g. acids)

- Stainless steel, can be sanitized with hot water

- Cleanability

- Hot water sanitization

- Biological compatibility

- Microbiological stabilisation with ozonisation

- Machine footprint

- Compact / Modular

- Material of construction

- Stainless steel

- Modular design

- Yes

- Expansion capability

- Modular add-ons

- Control panel type

- Touchscreen / PLC-based

- Discharge method

- Variable output regulation

- Cleaning type

- Hot water sanitizable

- Filtration system size

- 150 m³/h max flow rate

- Water processing range

- 5 to 120 m³ per hour

- Footprint flexibility

- Customizable layout

- Modular design

- Yes

- Control panel type

- Available

- Integration possibilities

- Customizable

- Modular component system

- Yes