Ultrafiltration system for heavy particle-laden process media

Designed for efficient particle removal, this advanced filtration technology optimizes process water treatment and resource recovery, minimizing energy consumption and maintenance while maximizing output quality. Ideal for handling challenging filtration tasks with precision and reliability.

Processes and Purifies Industrial Process Water

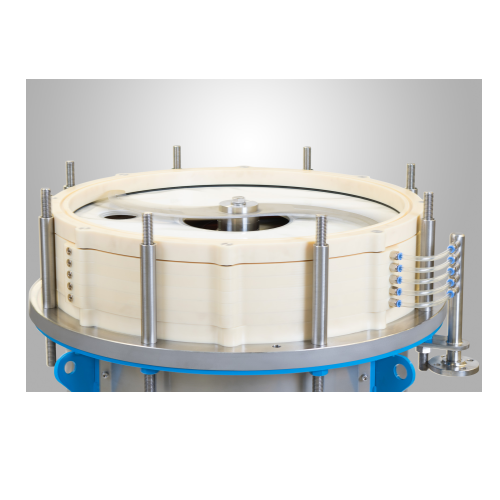

The BlueFilter from SPALECK offers a high-performance ultrafiltration system tailored for industries demanding efficient filtration of heavily particulate-laden process media. Utilizing flat membranes mounted on carrier plates, it features a rotating rotor above each membrane, maximizing crossflow and minimizing energy consumption. Ideal for steel and oil industries, the system processes industrial process water, crude oil, and laboratory-grade chemicals, and is scalable from lab-scale to large-scale operations. With an operational temperature capability up to 95°C, it ensures energy-efficient, continuous operation. Its patented rotor system prevents cake formation, reducing maintenance needs while enabling tool-free membrane changes. Suitable for environments requiring robust water purification, it integrates into existing setups with minimal disruption.

Benefits

- Minimizes energy usage through an efficient crossflow membrane design.

- Supports scalable deployment from small labs to large-scale operations.

- Reduces maintenance with tool-free membrane changes and anti-cake rotor technology.

- Operates continuously at high temperatures up to 95°C for diverse applications.

- Enhances filtration efficiency, ensuring superior purity in process water and valuable material recovery.

- Applications

- Wertstoffrückgewinnung, Prozesswässer, Labortechnik, Wasseraufbereitung, Ölindustrie, Stahlindustrie, Landwirtschaft

- End products

- Animal feed, Steel billets, Purified water, Recovered valuable materials, Laboratory-grade chemicals, Industrial process water, Crude oil

- Steps before

- Water intake, Screening, Coagulation, Sedimentation

- Steps after

- Disinfection, Storage, Distribution, Final quality check

- Input ingredients

- stark partikelbelastete Prozessmedien, Prozesswässer, Abwasser, schmutzige Flüssigkeiten

- Output ingredients

- gereinigtes Wasser, Wertstoffe, filtrierte Flüssigkeit

- Market info

- Spaleck is known for its expertise in designing and manufacturing innovative screening, separation, and conveying technology, particularly for recycling and bulk materials industries, and is reputed for high-quality, durable equipment tailored to customer specifications globally.

- Filtration System

- BlueFilter Ultrafiltration

- Filtration Type

- Ultrafiltration, Nanofiltration, Reverse Osmosis

- Energy Efficiency

- Minimal Energy Usage

- Operating Temperature

- Up to 95° C

- Scalability

- From Laboratory to Large-scale Systems

- Automation

- Manual / PLC Controlled

- Maintenance

- Tool-free Membrane Change

- Particulate Handling

- Effective for High Particulate Load

- Rotor System

- Patented for Enhanced Filtration

- Filtration Efficiency

- High Performance

- Application Temperature Range

- Up to 95° C

- Working mechanism

- Flachmembran with rotor system

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Minimal energy use

- Cleaning method

- Tool-free membrane change

- Process media compatibility

- Stark partikelbelastete Medien

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Filtration purpose

- Ultrafiltration / Nanofiltration / Reverse Osmosis

- Process media

- Strongly particle-laden process media

- Use case

- Wastewater treatment / Resource recovery

- DIN EN 15085-2

- CL1 Certification

- Compact footprint

- Customizable for lab and industrial scale

- Control panel type

- Integrated

- Discharge method

- Adjustable modular system

- Design type

- Flachmembranen on Trägerplatten

- Feed method

- Inline Rotor System

- Control panel type

- PLC-controlled

- Integration possibilities

- Custom integration for industry-specific requirements

- Modular system

- Scalable from lab to industrial scale

- Membrane type

- Flat/Tube/Spiral-wound

- Membrane material

- Custom materials based on application

- Operation temperature

- Up to 95° C

- Maintenance features

- Tool-free membrane replacement