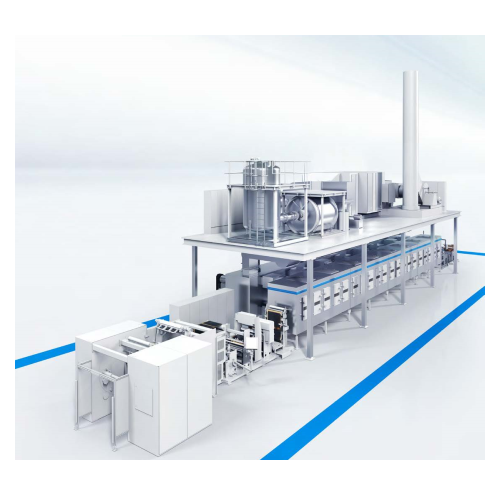

Battery electrode coating line

Optimize your battery production with a comprehensive coating line that enhances throughput and quality while ensuring environmental compliance through efficient solvent recovery and precise raw material handling.

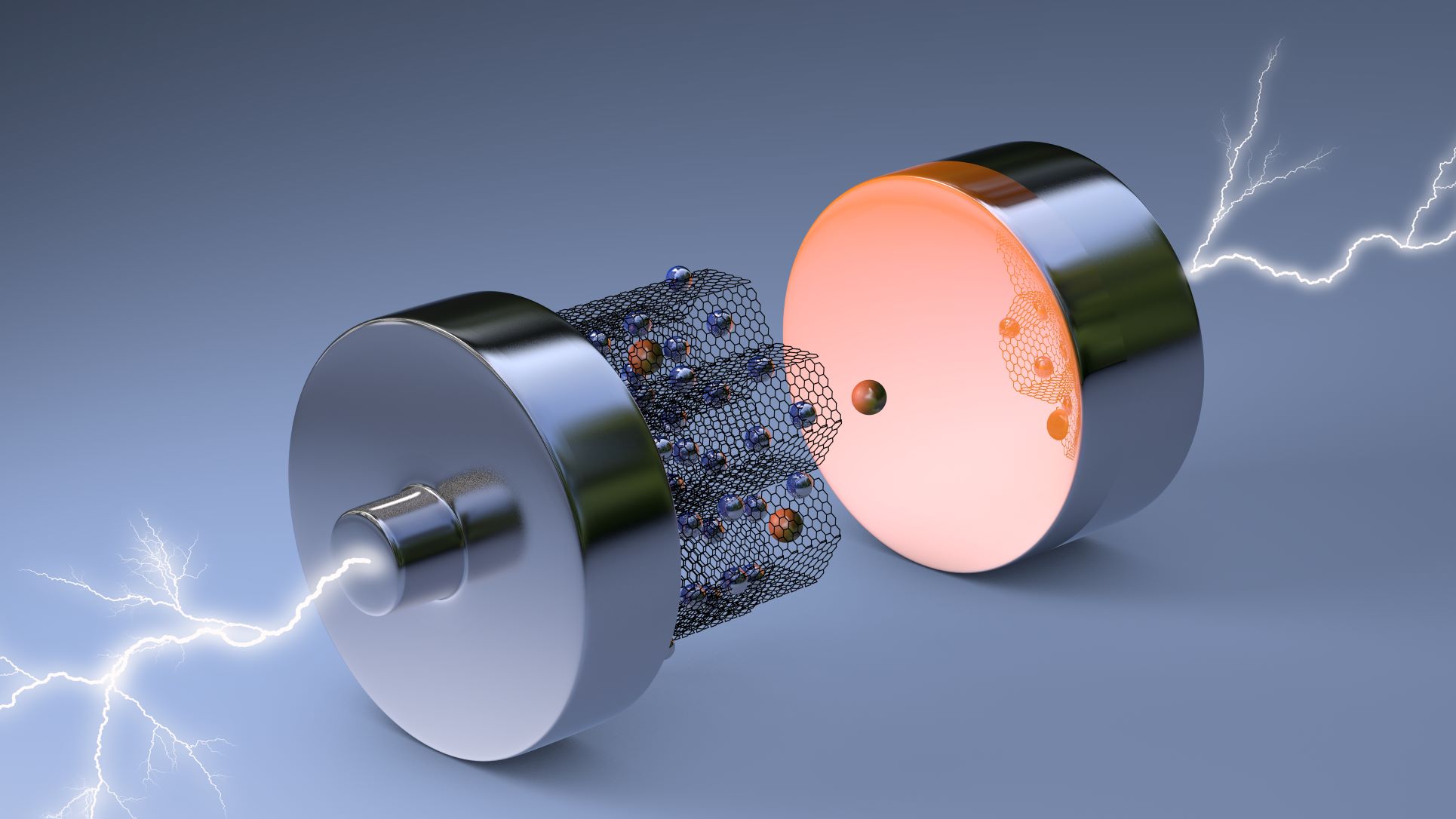

Processes and Coats Lithium-Ion Battery Electrode Materials

Dürr’s Lithium-Ion Battery Electrode Coating and Slurry Mixing System offers a comprehensive solution for manufacturing high-quality battery electrodes. This system excites automotive and battery manufacturers with its capability to improve production efficiency. It encompasses raw material handling, slurry mixing, web handling, and precise electrode coating. Engineered for continuous, high-volume operations, it supports the production of cathode and anode materials, as well as battery cells and modules. Automated features ensure seamless integration into existing production lines, enhancing throughput and quality control.

The system utilizes advanced coating technologies and efficient solvent recovery processes, increasing energy savings with optimized motor controls. Designed for diverse industrial applications, including automotive and chemical sectors, it meets stringent environmental compliance standards. Material options include corrosion-resistant configurations to ensure durability. Supported by Dürr’s engineering expertise, it includes turnkey installation, start-up supervision, and robust 24/7 service to maintain optimal performance.

Benefits

- Enhances production efficiency with seamless high-volume operation.

- Reduces energy costs through optimized motor control and solvent recovery.

- Ensures consistent product quality with integrated precision coating and mixing.

- Minimizes environmental impact by adhering to strict compliance standards.

- Streamlines maintenance with robust engineering support and quick response service.

- Applications

- Lithium-ion batteries, Batteries, Battery electrode materials

- End products

- Anode materials, Cathode materials, Battery modules, Battery packs, Lithium-ion battery cells

- Steps before

- Raw material handling, Slurry mixing, Fluid delivery

- Steps after

- Calendering, Slitting, Solvent recovery and purification

- Input ingredients

- raw material, slurry, fluid, lithium

- Output ingredients

- coated materials, lithium-ion electrode, solvent, purified solvent

- Market info

- Dürr is known for its expertise in industrial engineering and manufacturing solutions, specializing in automotive painting technology, environmental technology, and production efficiency systems. It has a strong reputation for innovation and quality in engineered-to-order equipment.

- Automation

- PLC-controlled

- Coating method

- Spray

- Solvent Recovery

- Yes

- System Capabilities

- Turnkey solution

- Equipment Installation

- Included

- Start-up Supervision

- Provided

- Service Support

- 24/7

- Material Handling

- Raw material handling system

- Slurry Mixing

- Included

- Web Handling

- Included

- Drying

- Included

- Calendering

- Included

- Slitting

- Included

- Environmental Compliance

- Included

- Turnkey solution

- Yes

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous

- Integrated processes

- Coating, drying, solvent recovery

- Changeover time

- Minimized

- Process development support

- Available

- 24/7 service and support

- Yes

- Installation and start-up supervision

- Included

- Corrosive resistance (e.g. acids)

- Lithium-Ion Battery Compatibility

- Density/particle size

- Compatible with slurry particle sizes

- Abrasion resistance

- Suits abrasive raw materials

- Cleanability

- Easy to clean for maintenance

- Biological compatibility

- Not applicable

- Coating line integration

- Turnkey

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Single-source OEM Integration

- Coating method

- Advanced laser coating

- Drying integration

- High-efficiency dryers

- Solvent recovery system

- Integrated solvent recovery system

- Turnkey solutions

- Complete production line setup