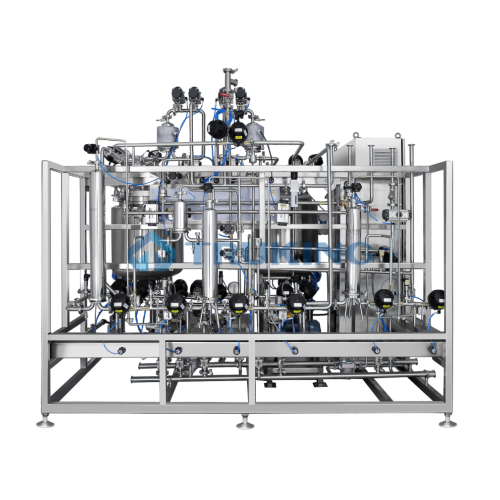

Pharmaceutical preparation system

Achieve seamless integration in pharmaceutical processes with a preparation system that optimizes production for liquid and lyophilized products, ensuring compliance and efficiency in every step.

Cultivates and Controls Biopharmaceutical Production

The Bioreactor System from TRUKING Technology Limited offers a state-of-the-art solution for biopharmaceutical and pharmaceutical manufacturing. This system employs precise environmental control to optimize cell cultivation, critical for producing injectable and lyophilized products such as vaccines and prefilled syringes. Designed for industries requiring stringent compliance, the system supports applications including protein solutions, oral liquids, and diagnostic reagents. Featuring compact modular skids, it integrates seamlessly into existing operations with one-touch automated processes. The bioreactor’s robust construction ensures material compatibility, and its CIP/SIP capabilities facilitate efficient cleaning and maintenance. Engineered to comply with international standards like GAMP, cGMP, and FDA, it promises reliability and consistency in high-demand production environments. Customization options are available to suit specific operational requirements, backed by comprehensive engineering support.

Benefits

- Ensures product consistency and quality with precise environmental control.

- Increases operational efficiency through seamless integration with continuous and automatic production lines.

- Minimizes contamination risk with CIP/SIP systems for efficient cleaning and maintenance.

- Meets stringent global compliance standards including GAMP, cGMP, and FDA, ensuring regulatory adherence.

- Offers flexible operation with customizable configurations tailored to specific production needs.

- Applications

- Freeze-dried applications, Pharmaceutical liquids, Injectable, Softbag production, Lyophilization production, Biopharmaceuticals, Oral liquids, Aerosols, Bfs production, Diagnostic reagent filling, Pre-filled syringe production, Ampoule production, Chinese traditional medicine, Oral preparation, Ophthalmic products

- End products

- Lyophilized diagnostic agents, Protein solutions for biopharmaceuticals, Freeze-dried vaccines, Vaccine vials, Prefilled syringes for biologics, Cough syrups, Herbal extract capsules, Diagnostic test kits, Inhalation solutions, Intravenous drip bags, Eye drops, Insulin ampoules

- Steps before

- Purification, Separation, Extraction, Concentration

- Steps after

- Sterilization, Packing, Inspection, Leakage Testing

- Input ingredients

- pharmaceutical ingredients, oral liquids, aerosols, ophthalmic solutions

- Output ingredients

- freeze-dried products, oral liquid preparations, ampoules, pre-filled syringes, soft bags

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Automation

- Fully automatic

- Compliance

- GAMP, cGMP, FDA

- Control system

- Industrial PC control

- Data integrity

- 21 CFR Part 11 compliance

- Design simulation

- 3D simulation

- Feature

- Online CIP/SIP

- Modular design

- Compact modular skids

- Product residue

- Minimum

- Quality control

- In-house fabrication

- Utility consumption

- Optimized

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Industrial PC control

- Machine footprint

- Compact modular skids

- Tank shape and size

- In house fabrication with customizable design

- Control panel type

- Industrial PC control

- Integration possibilities

- Remote access

- Modular design

- Compact modular skids

- Process System Customization

- Customized solutions for pharmaceutical and bio-pharmaceutical industries