Wiped film evaporator for high boiling point materials

For challenging separations of high boiling, viscous, or heat-sensitive materials, this technology efficiently handles evaporation and distillation, ensuring product integrity with minimal thermal degradation.

Efficiently Separates and Purifies Heat-Sensitive Materials

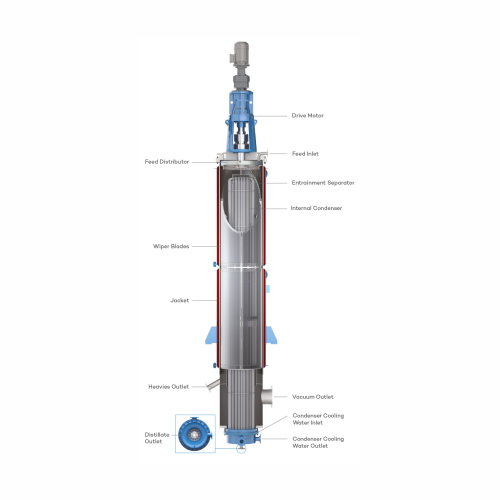

The EQUILLOY Wiped Film Evaporator by GMM Pfaudler is engineered to effectively process high viscosity, heat-sensitive, and fouling materials. It operates under high vacuum with a mechanically agitated thin film of feed material applied to a heated surface, ensuring optimal heat transfer and minimal thermal degradation. Designed for continuous operation, this equipment is suitable for industries such as chemical, pharmaceutical, and food processing, with applications including silicone rubber, omega-3 supplements, and bio-oil.

With sizes ranging from 1.2 to 500 sq. ft., it meets various processing requirements. The robust design includes an internal condenser for true short-path distillation, resulting in minimized pressure drops and reduced costs. The use of resistant materials like stainless steel and glass-lined steel ensures longevity and chemical compatibility. The system is PLC-controlled, offering seamless integration into existing production lines and remote monitoring. Maintenance is efficient, with a design allowing quick rotor removal and mechanical seal replacement, all while promoting energy savings through low rotor speed.

Benefits

- Minimizes thermal degradation with short residence time for enhanced product quality.

- Reduces operational costs through energy-efficient low rotor speed.

- Increases processing flexibility with sizes up to 500 sq. ft.

- Enhances separation purity due to high vacuum operation and entrainment separators.

- Facilitates easy maintenance with quick rotor removal and accessible mechanical seals.

- Applications

- Polymers, High boiling point products, High viscosity materials, Nutraceuticals, Chemical products, High fouling products, Energy sector products, Used motor oil re-refining, Pharmaceutical products, Resins, Food products, Heat sensitive products

- End products

- Gelatin capsules, Silicone rubber, Epoxy resins, Vinyl ester resins, Omega-3 fish oil supplements, Crude oil distillates, Bisphenol-a (bpa) free polycarbonate, Bio-oil from pyrolysis, Medium-chain triglycerides (mct) oil, Lubricating oil base stocks, Essential oils

- Steps before

- Purification, Mixing, Pre-heating, Grinding

- Steps after

- Distillation, Condensation, Filtration, Final polishing

- Input ingredients

- high boiling point products, high viscosity materials, heat sensitive products, fouling products, viscous materials like polymers and resins, used motor oil, high molecular weight materials

- Output ingredients

- volatile compounds, distillate product, purified and separated components

- Market info

- GMM Pfaudler is known for manufacturing glass-lined equipment, reactors, and engineered-to-order (ETO) solutions for the chemical, pharmaceutical, and allied industries, recognized for their innovation, quality, and global presence.

- Evaporation Size Range

- 1.2 sq. ft. (0.1 sqm) to 500 sq. ft. (46.5 sqm)

- Operating Vacuum

- 0.001 Torr

- Material of Construction

- Stainless steel, duplex stainless steels, high nickel alloys, glass, glass-lined steel

- Vacuum System Integration

- Complete vacuum system integration

- Feed Type

- High viscosity, heat sensitive, fouling, high boiling point materials

- Internal Condenser

- True short-path distillation for minimized pressure drops

- Entrainment Separator

- Low pressure drop and high vapor flow rate

- Horsepower Requirements

- Low due to low rotor speeds

- Wiper Blade Material,Design

- Several designs and materials based on operating conditions

- Residence Time

- Measured in seconds

- Drive Unit Design

- Over-hung rotor design, robust drive

- Operating vacuum level

- As low as 0.001 Torr

- Short residence time

- Measured in seconds

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Internal condenser

- True short-path distillation

- Automation level

- PLC-controlled

- High vacuum distillation

- Yes

- Energy efficiency

- Low energy consumption

- Entrainment separation

- Full-length entrainment separators

- Corrosive resistance (e.g. acids)

- Yes

- Viscous Materials

- Yes

- Construction Material

- Stainless steel / Duplex stainless steels / High nickel alloys / Glass / Glass-lined steel

- Pressure Vessel Codes

- Most Major Worldwide Codes

- FDA Compliance

- Materials and Process

- GMP Compliance

- Processing of Pharmaceuticals and Chemicals

- ISO Standards

- Design and Manufacturing Processes

- WFE Sizes

- 1.2 sq. ft. (0.1sqm) to 500 sq. ft. (46.5sqm)

- Material of Construction

- Stainless steel, duplex stainless steels, high nickel alloys, glass, glass-lined steel

- Feed Method

- Mechanically agitated thin film

- Discharge Method

- Bottoms outlet with extruder blades for high melting point materials

- Internal Condenser

- Included for true short path evaporation

- Size Range

- 1.2 sq. ft. (0.1 sqm) to 500 sq. ft. (46.5 sqm)

- Internal Condenser Integration

- Yes

- Rotor Removal,Maintenance

- Easy Removal (30 minutes or less)

- Entrainment Separator Design

- Variety of Designs Available

- Wiper Blade Design,Material

- Several Options Available

- Drive Design

- Over-hung with No Bottom Bearing

- Expandable Thermal Sections

- Yes

- Material of Construction

- Stainless Steel, Glass, Glass-Lined Steel