Hydrogen refueling stations planning and construction

Facing challenges in setting up hydrogen infrastructure? Our solution streamlines the planning and construction of hydrogen refueling stations to efficiently support and expand hydrogen energy use.

Refuels Hydrogen for Transportation and Industrial Applications

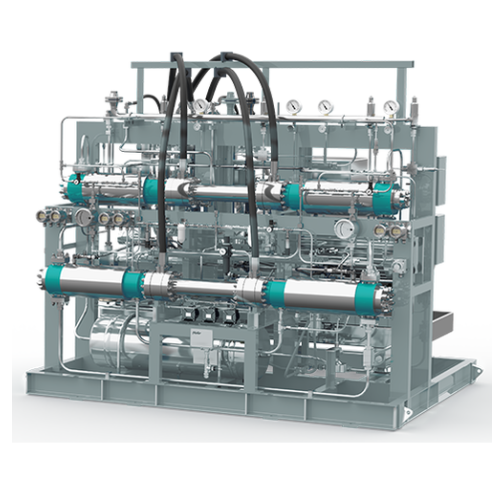

The Hydrogen Refueling Station solutions from Neuman & Esser are engineered to meet the demanding needs of the hydrogen economy, offering comprehensive infrastructure for hydrogen distribution and refueling. These stations are uniquely designed to integrate compression, storage, and dispensing processes, ensuring seamless operations tailored for continuous and high-speed environments. Application-specific configurations cater to fleet operators, refueling station operators, and industrial gas companies. Utilizing advanced simulation and monitoring technology, these stations optimize hydrogen availability and throughput with precise control. Constructed with high-grade materials, they provide robustness under various operational conditions. These stations support liquid and compressed hydrogen, generated either on-site via PEM electrolyzers or supplied through centralized production hubs. They offer a scalable solution, easily adaptable to existing logistics networks, enhancing the transition to a sustainable energy infrastructure.

Benefits

- Ensures high hydrogen availability and quick refueling, enhancing fleet efficiency.

- Integrates seamlessly into existing logistics networks, expediting deployment and scaling.

- Minimizes operational costs by utilizing advanced simulation and monitoring technologies.

- Supports environmental sustainability by enabling the use of green hydrogen.

- Offers customizable configurations, ensuring alignment with specific operational needs and regulatory requirements.

- Applications

- Oil and gas industry, Green gas industry, Biogas upgrading, Fuel cell electric vehicles, Circular economy, Hydrogen economy, Hydrogen production systems, Industrial gas processing, Energy infrastructure

- End products

- Liquid hydrogen, Recovered carbon black, Hydrogen refueling stations, Hydrogen for industrial gas applications, High-performance battery systems, Compressed hydrogen gas, Green hydrogen, Purified hydrogen gas for fcev, Bio-ethanol, Bio-methane, Pem electrolyzers

- Steps before

- Site evaluation, Feasibility study, Financing, Hydrogen production, Gas treatment, System design, Simulation, Planning

- Steps after

- Optimization, Physical construction, Commissioning, Monitoring, Data collection, Fleet operations planning

- Input ingredients

- water, biomethane, bioethanol, electricity, hydrogen gas

- Output ingredients

- hydrogen fuel, compressed hydrogen, liquid hydrogen, purified hydrogen gas

- Market info

- Neuman & Esser Group is known for its expertise in manufacturing compressors and grinding systems. They hold a strong reputation for providing durable, high-quality engineered-to-order equipment, particularly in the oil and gas, chemical, and energy industries.

- Hydrogen Refueling Station Pressure

- 350 bar / 700 bar

- Compressor Pressure

- 200 and 900 bar

- Electrolyzer Power

- 300 kW

- Hydrogen Production Pressure

- 30 bar

- Hydrogen Dispenser for Vehicles

- Yes

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg hydrogen

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- PLC / HMI

- Integration possibilities

- NEA|XPLORE system

- Design configurations

- Stationary / Hub and Spoke / Mother, Daughter

- Hydrogen supply method

- Pressurized/Cryogenic trailers / Pipeline / On-site generation

- Cooling system type

- On-site cooling integrated

- Hydrogen purification unit inclusion

- Required for pipeline supply

- Simulation and design software

- HRS-simulation program

- Data monitoring and collection

- Cloud-based NEA|XPLORE system