Hollow fiber membranes for wastewater treatment

Ensure consistent, high-quality effluent from industrial water and wastewater applications with advanced hollow fiber membrane filtration technology designed to tolerate high solids and minimize downtime.

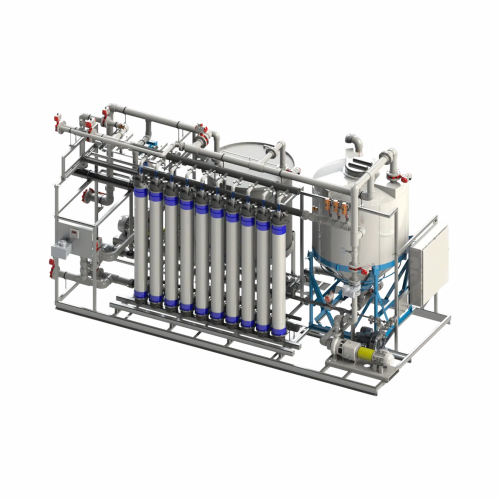

Purifies and Clarifies Water and Wastewater

The PURON® HF and PURON® MP systems from Kovalus Separation Solutions are state-of-the-art hollow fiber membrane filtration systems designed to enhance water purification across a range of applications. Distinguished by their virtually unbreakable fibers and compact design, these systems efficiently process industrial and potable water, wastewater, and seawater. Operating on a pressurized hollow fiber ultrafiltration principle, they deliver high-quality effluent while reducing pre-treatment and maintenance costs. Suitable for diverse industries such as food and beverage, life sciences, and municipal facilities, these systems handle varying suspended solid levels with ease. The PURON® HF provides more than 95% recovery, surpassing regulatory standards, and integrates seamlessly into existing production lines with skid-mounted and modular configurations. Designed to meet stringent certifications, including NSF/ANSI Standard 61, this equipment ensures compliance and reliability. Its robust construction, designed for continuous operations, minimizes downtime and maximizes efficiency, offering an effective solution for water treatment challenges.

Benefits

- Maximizes operational efficiency with high solids tolerance, minimizing pre-treatment requirements.

- Reduces maintenance downtime with virtually unbreakable hollow fiber membranes.

- Achieves over 95% system recovery, ensuring consistent regulatory-compliant effluent quality.

- Offers flexible installation with pre-engineered skid-mounted and modular system options.

- Ensures corrosion resistance and compliance with NSF/ANSI Standard 61 for safe water treatment.

- Applications

- Surface water treatment, Industrial water, Potable water treatment, Seawater pretreatment, Wastewater treatment

- End products

- Drinking water, Desalinated seawater, Industrial process water, Treated wastewater effluent, Clarified surface water

- Steps before

- Pretreatment, Purification, Seawater Pretreatment, Tertiary Treatment

- Steps after

- Regulatory Compliance Testing, Effluent Quality Monitoring

- Input ingredients

- wastewater, surface water, seawater, municipal water, industrial water, potable water

- Output ingredients

- high-quality effluent, consistent effluent, potable water, treated water, clean water meeting regulatory standards

- Market info

- Kovalus Separation is known for manufacturing industrial engineered-to-order (ETO) separation equipment, specializing in tailored solutions for complex filtration and separation needs, with a strong reputation for innovation, quality, and reliability in various industries.

- Membrane Type

- Polyester reinforced PVDF

- Filtration System

- Hollow Fiber Ultrafiltration

- System Recovery

- More than 95%

- Effluent Quality

- Meets LT2 specifications

- Membrane Area

- 44% more than PURON® MBR module

- Automation

- Pre-engineered package plants

- Compact Footprint

- High throughput within compact size

- Modules

- Skid-mounted and modular systems

- Solids Tolerance

- High tolerance to suspended solids

- Performance

- Consistent high-quality effluent

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Water Treatment Applications

- Potable, Wastewater, Surface water

- Filtration Type

- Pressurized hollow-fiber ultrafiltration

- Compact footprint

- Yes

- Control panel type

- Integrated

- Discharge method

- Pressurized hollow-fiber

- Membrane area increase over MBR module

- 44%