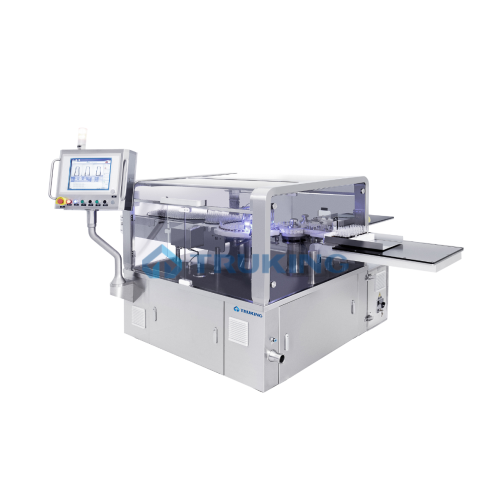

Automatic inspection system for sealing defects in ampoules

Ensure flawless ampoule sealing with a high-precision inspection system, designed to detect critical defects like burnt heads and bubbles, enhancing product integrity before it reaches packaging.

Performs Precise Freeze Drying for Pharmaceuticals

The freeze dryer from TRUKING is engineered for the pharmaceutical and biotech sectors, delivering precise and efficient lyophilization. This equipment utilizes a multi-shelf chamber design to enable uniform drying, essential for developing stable vaccines, antibiotics, and oncology drugs. Capable of processing large batches, it reduces energy consumption by integrating an optimized refrigeration system. The PLC control system ensures seamless integration into existing lines, featuring remote operation and monitoring for improved oversight. Constructed from stainless steel, it complies with cGMP and FDA standards, ensuring robust performance and reliability. Maintenance is streamlined with an incorporated CIP system, minimizing downtime and contamination risks, with customization options available to fit specific production requirements.

Benefits

- Enhances product stability and shelf-life through uniform moisture removal.

- Reduces operational costs with energy-efficient refrigeration technology.

- Ensures seamless integration with PLC-controlled remote monitoring capabilities.

- Simplifies maintenance and minimizes contamination risk with CIP system.

- Complies with cGMP and FDA standards for reliable pharmaceutical production.

- Applications

- Pharmaceutical powder, Softbag production, Biopharmaceuticals, Oral liquid production, Diagnostic reagent formulations, Pre-filled syringe production, Injectable lyophilization, Ampoule production, Chinese traditional medicine

- End products

- Oncology drugs, Vaccines, Iv fluid bags, Pre-filled insulin syringes, Antibiotics, Vitamin supplements, Cough syrup, Hormone treatments, Eye drops, Antiviral drugs, Blood coagulation factors, Freeze-dried injections, Herbal extract

- Steps before

- Extraction, Concentration, Drying, Purification, Reaction, Crystallization

- Steps after

- Sterilization, Packing, Inspection, Sealing, Labeling, Secondary Packaging

- Input ingredients

- sterilizing agents, pharmaceutical raw materials, liquid formulations, diagnostic reagents, oral liquid formulations, biological cultures, Chinese traditional medicine materials

- Output ingredients

- freeze-dried products, filled ampoules, filled vials, soft bags, glass bottles, plastic bottles, sealed ampoules, packaged items, oral liquid products, diagnostic reagents

- Market info

- Truking is known for manufacturing engineered-to-order pharmaceutical equipment, specializing in liquid and solid preparation systems. They have a strong reputation for innovation and quality in the pharmaceutical machinery sector.

- Automation

- Servo mechanical system

- Control System

- Industrial PC control

- Data Integrity

- 21 CFR Part 11 compliance

- Defect Detection

- Ampoule sealing defects such as burnt head, tailing, bubble head

- Light Source Control

- LED light source color control

- Remote Access

- Available

- RPM Rate Control

- Customizable

- Servo Mechanical System

- State of art

- Software

- State of art software

- System Compliance

- GAMP, cGMP compliance

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Variety

- Control panel type

- Advanced HMI with remote access

- Integration possibilities

- Integration with MES/ERP systems

- Customization for product handling

- Custom recipes for product variations

- Software customization

- Graphical debugging and data integrity

- Remote access capability

- Yes, compliant with 21 CFR Part 11