Waste heat recovery technology for industrial applications

Capture and utilize waste heat from industrial processes to enhance energy efficiency and reduce emissions, transforming excess thermal energy into valuable resources for your carbon capture and sustainable production goals.

Recovers and Utilizes Waste Heat Efficiently

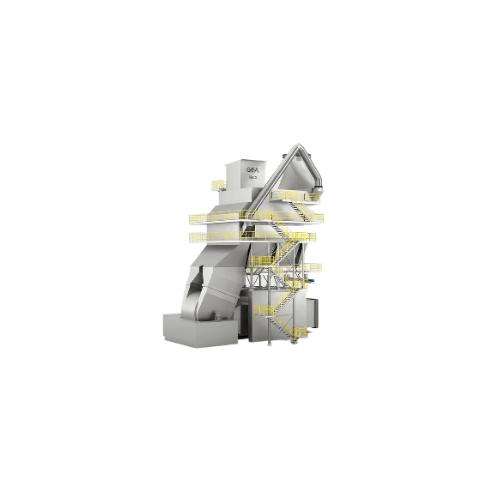

The XECO Waste Heat Recovery System from GEA offers an efficient solution for capturing and utilizing waste heat in cement and glass industries. Designed for continuous operation, it uses a heat exchanger and carrier loop to transfer excess thermal energy for carbon capture and emission control. Optimizing parameters like gas velocity and pipe dimensions enables it to handle high dust content flue gases, maintaining stability and reliability. The system supports applications such as kiln exhaust treatment, clinker cooling optimization, and sustainable heat use in glass production. It integrates seamlessly into production lines, reducing external energy needs and enhancing overall process sustainability. Available for use with thermal oil or water heat transfer mediums, it adheres to stringent environmental compliance standards, ensuring safety and efficiency. Customizable designs with GEA’s engineering support further enhance application-specific performance.

Benefits

- Lowers energy expenses by utilizing waste heat for carbon capture.

- Integrates into existing processes with minimal disruption.

- Handles high dust content effectively, ensuring stable operation.

- Enhances sustainability with reduced reliance on external energy sources.

- Reduces maintenance needs through optimized, reliable design.

- Applications

- Emission control systems, Waste heat recovery, Glass, Heat-intensive production, Carbon capture solutions, Thermal energy transfer, Industrial processes, Cement

- End products

- Amine-based co2 capture, Orc electricity generation, Value-added co2-based products, Refined flue gases for particle reduction, Kiln exhaust gas treatment, Sustainable heat utilization in glass production, High-efficiency heat exchangers, Sulfuric and nitric oxide removal, Liquefied co2 storage, Clinker cooling optimization

- Steps before

- Scrubbing, Dedusting, Denitrification, Gas Pre-Treatment, Cooling, Condensing, Removal of Solids

- Steps after

- Carbon Capture, ORC Applications, Heat Utilization, Heating, Electricity Generation, Sequestration

- Input ingredients

- flue gases, exhaust gases, thermal energy, process gas, dust-laden gas

- Output ingredients

- captured CO2, reusable thermal energy, carbon capture feed, waste heat for ORC/CEBO plants, cleaned gas

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Heat Carrier Medium

- Thermal oil / Water

- Process Gas Contact

- Cross-counter current

- Dust Content Handling

- High dust content (> 10g/m³ std. dry)

- Heat Exchanger Design

- Customizable for specific flue gases

- Operating Parameters

- Optimized gas velocity, pipe diameter, pipe thickness

- Application Suitability

- Cement kiln exhaust, Glass industry

- Heat Recovery

- Waste heat reutilization for CO2 capture

- Integration Capability

- ORC applications, CEBO Carbon Capture

- Working mechanism

- Heat exchanger and heat carrier loop

- Integrated steps

- Heat transfer to amine solvent

- Automation level

- Optimized with PLC for operating parameters

- Batch vs. continuous operation

- Continuous flow

- Cleaning method

- CIP / Manual

- Energy efficiency

- Utilizes waste heat to reduce external energy

- Compatibility with high-dust content

- > 10g/m3std. dry

- Footprint

- Compact/Variable

- Heat Exchanger Type

- Cross-counter Current

- Material Thickness

- Customized per Requirement

- Heat Carrier Medium

- Thermal Oil/Water

- Dust Handling Capability

- High (> 10g/m³ std. dry)

- Customization Level

- Tailored to Process Requirements

- Control panel type

- HMI touch screen

- Integration possibilities

- Seamless integration with Carbon Capture Units

- WHRU Pipe specifications

- Variable diameter and thickness

- Heat carrier medium

- Thermal oil or water