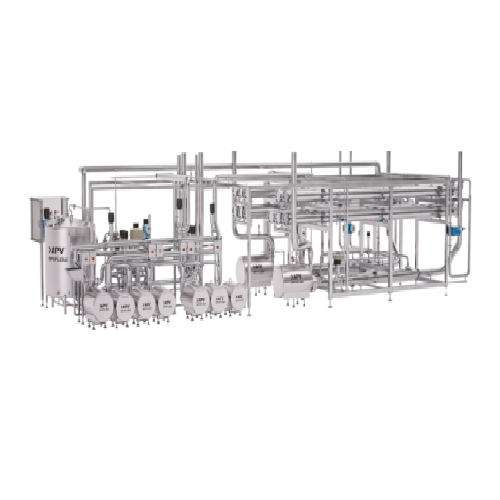

Reverse osmosis system for dairy and plant-based processing

Enhance your production line with high-pressure reverse osmosis, designed to effectively concentrate dairy and plant-based beverages, ensuring efficient pre-concentration and purification, while minimizing energy use and transport costs.

Concentrates and Purifies Dairy and Plant-Based Liquids

The Reverse Osmosis (RO) Membrane Filtration System is engineered for efficiency in dairy and plant-based processing applications. Utilizing a dense membrane composition and high-pressure operation, it effectively separates water from dissolved and suspended solids, enabling high levels of concentration and purification in liquids and slurries.

Applications include concentrating whey protein, lactose-free milk, and plant-based beverage solutions, with the potential to enhance nutritional profiles, such as producing high-protein milk concentrates. Its integration allows pre-concentration of fluids to minimize transport costs and facilitates downstream processes like evaporation.

With operational pressures reaching up to 40 bar, this system is designed for continuous processing, ensuring minimal downtime and maintenance. The unit supports energy efficiency and operator-friendly interfaces, reducing the carbon footprint while maintaining high-performance membrane life.

Constructed for versatility, it handles various product types and sizes, offering customization in material choice to withstand different chemical environments, including high-grade stainless steel options. Intelligent control systems integrate seamlessly with existing production lines, allowing for remote monitoring and automation enhancements.

Compliant with industry standards, the system delivers robust processing capabilities while providing CIP (Clean-In-Place) features that streamline maintenance and ensure hygiene standards are met, aligning with sustainability goals across dairy and plant-based production environments.

Benefits

- Optimizes production efficiency by concentrating more solids, reducing transport and storage costs.

- Supports sustainability goals with reduced energy consumption and CO2 emissions.

- Enhances product quality through precision filtration, ensuring high-purity outputs.

- Minimizes operational interruptions with durable membranes and continuous flow design.

- Facilitates easy integration into existing lines, enhancing overall production flexibility.

- Applications

- Plant-based beverages, Sweet buttermilk, Skim milk, Uf permeate, Whey, White water, Dairy products, Whole milk

- End products

- Soy milk concentrate, Nutritional supplements from whey, Protein-rich buttermilk, Concentrated whey protein, High-protein milk concentrates, Non-fat dry milk, Lactose-free milk, Reduced lactose sweet whey, Almond milk concentrate, Plant-based milk solutions

- Steps before

- Filtration, Pre-concentration, Purification

- Steps after

- Evaporation, Process water generation, Wastewater treatment, Capacity increase, Transport

- Input ingredients

- whey, UF permeate, skim milk, whole milk, white water, sweet buttermilk, plant-based beverages

- Output ingredients

- concentrated whey, concentrated UF permeate, concentrated skim milk, concentrated whole milk, concentrated plant-based beverages

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Membrane Type

- Very dense membrane

- Operation Pressure

- Up to 40 bar

- Substance Rejection Capability

- Virtually all substances except water

- Process Integration

- In-line for UF, RO, RO polisher

- Energy Efficiency

- Green technology

- System Design

- Pre-assembled in manufacturing facilities

- Membrane Lifetime

- High performance and long membrane lifetime

- Pressure Utilization

- Overcomes osmotic pressure

- Working mechanism

- Reverse Osmosis with high system pressure

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- CIP capable

- Automation level

- Manual / PLC

- Changeover time

- Minimal due to pre-assembled systems

- Energy efficiency

- Efficient, reduced carbon footprint

- Cleaning method

- CIP

- Membrane type

- Very dense membrane

- Operating pressure

- Up to 40 bar

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Discharge method

- Inline process

- Control panel type

- Operator friendly interface

- Pressure rating

- Up to 40 bar