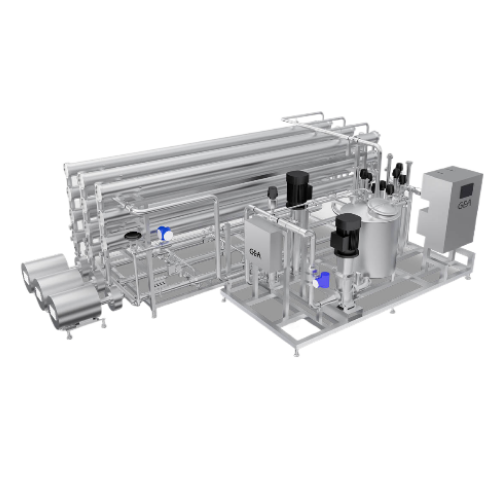

Membrane filtration unit for hard seltzer production

Effortlessly produce a clear, aroma-free base for hard seltzers by eliminating unwanted compounds through advanced membrane filtration, ensuring a high-quality foundation for flavored alcoholic beverages and innovative product lines.

Processes and Purifies Alcoholic Bases for Hard Seltzer

The GEA Membrane Unit to Produce Hard Seltzer offers beverage manufacturers and breweries a specialized solution for crafting clear, aroma-free alcoholic bases. Utilizing cross-flow membrane filtration, it efficiently removes unwanted flavors and aromas, ensuring a high-quality output suitable for hard seltzer production. Designed for both batch and continuous operations, it can be customized to accommodate varying plant capacities and integrates easily into existing setups. The unit boasts a dedicated clean-in-place (CIP) system for streamlined maintenance. Constructed with durable polymeric membranes, it ensures long-term performance with reduced operational costs. Its compact, modular design allows for seamless expansion and integration into diverse production environments, while its energy-efficient operation lowers OPEX compared to alternative technologies.

Benefits

- Ensures premium quality with a neutral, flavorless alcoholic base.

- Minimizes operational costs through energy-efficient design.

- Integrates seamlessly into existing production lines for streamlined operations.

- Reduces manual intervention with automated processing capabilities.

- Expands production capabilities easily with modular and scalable design.

- Applications

- Beverages, Fermented sugar solutions, Alcoholic beverages, Cider, Hard seltzer, Beer

- End products

- Aroma-free alcoholic beverage, Refined cider, Purified beer, Neutral alcoholic malt base, Clear alcoholic base for hard seltzer, Flavorless hard seltzer base

- Steps before

- Fermentation

- Steps after

- Mixing, Blending, Polishing, Carbonation, Flavor Addition, Packaging

- Input ingredients

- fermented sugar solution, simple sugar, residual sugar, salts, long-chain color components, aroma components

- Output ingredients

- neutral alcoholic base, clear alcohol base, tasteless alcohol base, aroma-free alcohol base, pure seltzer base

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Membrane Type

- Polymeric

- Filtration Type

- Cross-flow filtration

- Operation Mode

- Batch or Continuous

- Automation

- Automatic operation

- CIP System

- Integrated clean-in-place (CIP) system

- Capacity

- Customizable plant sizes and capacities

- Yield

- High yield

- Neutral Alcohol Base Quality

- Clear, tasteless, aroma-free

- Additional Polishing Step

- Optional

- Integration

- Easily integrated into existing systems

- Batch vs. continuous operation

- Batch / Continuous

- Automation level

- Automatic

- Integration capability

- Easily integrated into existing plant

- CIP/SIP

- Dedicated CIP system

- Flexibility

- Modular and expandable

- Operating efficiency

- High yield, low OPEX

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Low, due to membrane filtration

- Compact footprint

- Yes

- Modular design

- Yes

- Discharge method

- Batch or continuous

- Integration capability

- Easy integration into existing systems

- Control panel type

- Automated

- Tank shape and size

- Customizable

- Feed/discharge method

- Membrane filtration

- Control panel type

- Automated / PLC-controlled

- Integration possibilities

- Modular units for existing brewery lines

- Operation mode

- Batch or continuous

- Clean-in-place (CIP) system

- Dedicated CIP system

- Polishing step

- Optional for higher quality base

- Expandability

- Easily expandable for increased capacity