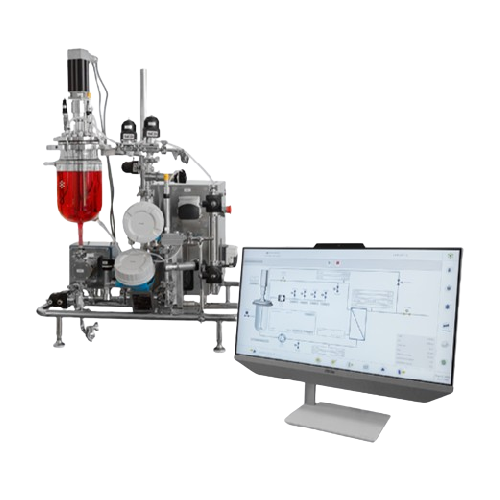

Benchtop tangential flow filtration system

Ensure high-purity yields and streamline your filtration processes with this benchtop tangential flow system, ideal for compact lab environments seeking efficient liquid handling and precise separation capabilities.

Processes Filtration, Separation, and Purification

The TFF KRONOS from Solaris is a benchtop Tangential Flow Filtration System tailored for diverse applications in the biotech, pharmaceutical, and chemical industries. Designed to integrate smoothly into laboratory and development environments, it excels in filtration, separation, ultrafiltration, microfiltration, and diafiltration processes, accommodating volumes from 2L to 10L. It features a robust, autoclavable glass vessel with flexible membrane options like hollow fiber, cassettes, and ceramic for optimal performance across a 0.5 m² filtration area. Equipped with a precision brushless motor, the TFF KRONOS offers variable speeds from 1 to 2000 RPM, ensuring consistent processing. Its modular design supports batch and fed-batch operations, with automation handled by Modbus-connected sensors and an intuitive SCADA Lab View software, guaranteeing seamless process control and data integrity (CFR21 part 11 compliant). Additional features like integrated NPW testing, automated filtrate flow control, and comprehensive filter history management underscore its efficiency and reliability. Constructed to cGMP standards, the TFF KRONOS promises easy maintenance, accommodating various industry needs with options for advanced filter material selection, and specialized engineering support from Solaris technicians, ensuring alignment with specific operational parameters.

Benefits

- Enhances purification precision for biopharmaceuticals and APIs, ensuring high product quality.

- Increases operational efficiency with customizable process sequences and remote monitoring.

- Minimizes lab space usage with its compact footprint.

- Meets stringent industry standards with cGMP construction and CFR21 part 11 compliance.

- Provides flexible filtering options to accommodate varying separation needs.

- Applications

- Fine chemicals, Nutraceuticals, Biopharmaceuticals, Enzymes, Pharmaceuticals

- End products

- Insulin, Active pharmaceutical ingredients (apis), Monoclonal antibodies, Proteases, Herbal extracts, Dietary supplements

- Steps before

- Preparation of feed solution, Pre-filtration, Adjustment of pH

- Steps after

- Concentration, Diafiltration, Sterilization

- Input ingredients

- feed solution, liquid mixture

- Output ingredients

- permeate, retentate, concentrate, filtrate

- Market info

- Solaris Biotech is known for manufacturing specialized engineered-to-order bioprocessing equipment, including fermenters and bioreactors, with a strong reputation for innovation, quality, and customization capabilities in the biotechnology and pharmaceutical markets.

- Volume

- 2L, 5L, 10L

- Filtration Area

- Up to 0.5 m²

- Membrane Types

- Hollow fiber, cassettes, ceramic

- Motor Speed

- 1 to 2000 RPM

- Optional Flow Control

- Filtrate flow control

- Automation

- Automated process sequence

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- SCADA / PLC controlled

- CIP/SIP

- Autoclavable glass vessel

- Cleaning method

- Autoclavable / Manual

- Integrated steps

- Automated process sequence

- Working mechanism

- Tangential Flow Filtration

- Changeover time

- Flexible filter holders

- Energy efficiency

- Smart sensors / low power

- Air incorporation control

- Integrated NPW test

- Cleanability

- Autoclavable

- Application Range

- Batch and fed batch ultrafiltration, microfiltration, diafiltration

- GMP Compliance

- cGMP

- Machine footprint

- Small footprint to maximize lab space efficiency

- Vessel type

- Jacketed and autoclavable glass vessel

- Capacity

- Available in 3 volumes

- Filtration area

- Up to 0.5 m² total filtration area

- Discharge method

- Recirculation vessels and valves module conveniently located

- Motor type

- Powerful and accurate brushless motor, from 1 to 2000 RPM

- Filter holders

- Flexible filters holders

- Control panel type

- Modbus digital sensors

- Flexibility in membrane types

- Hollow fiber, cassettes, ceramic

- Integration possibilities

- Wireless connection, remote access

- Volume options

- 2L, 5L, 10L

- Filtration area

- Up to 0.5 m²