Aromatic recovery unit for refineries

Ensure compliance with stringent emission standards by effectively recovering and separating aromatic compounds from vapor streams, offering a robust and safe solution for continuous, automated operations.

Recovers Aromatic Vapors and Controls Emissions

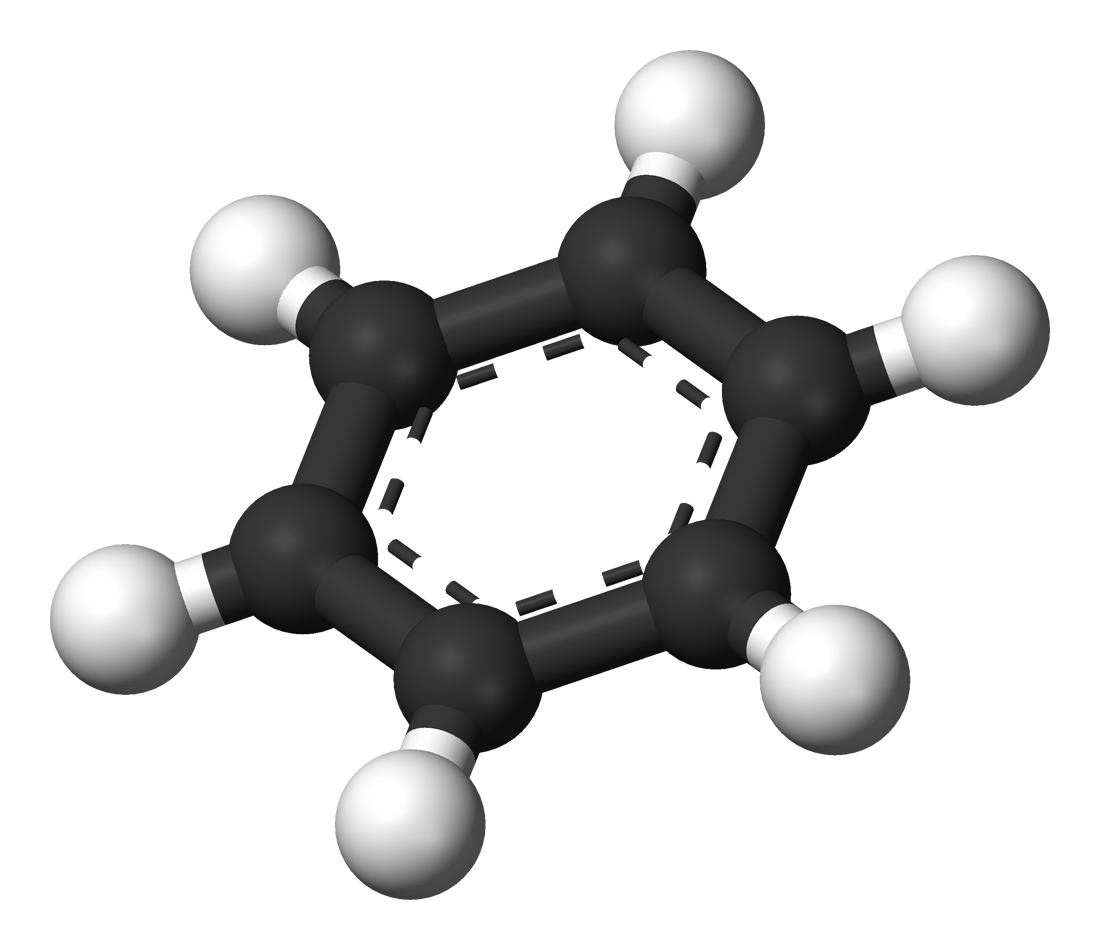

The BORSIG Aromatic Recovery Unit offers an advanced solution for managing emissions in petrochemical environments. This unit employs a specialized BORSIG membrane process for high-efficiency vapor recovery, ensuring compliance with global emission standards. It integrates seamlessly into continuous production lines in refineries and terminals, specifically targeting benzene, toluene, and xylene vapors. The system operates automatically with a robust PLC control, enabling remote monitoring and adjustments to optimize throughput. Engineered for industrial robustness, it supports a wide range of hydrocarbon accessibilities while minimizing energy consumption. Maintenance is simplified through a contamination-free CIP system, ensuring longevity and maximal uptime. Additionally, the unit is available with customization options for varied production needs and comes in corrosion-resistant materials to suit harsh industrial conditions.

Benefits

- Ensures regulatory compliance by maintaining emissions below 1 mg benzene/m³.

- Enhances operational safety with no contamination or expensive disposal of process fluids.

- Prolongs equipment lifetime with stable and efficient process design.

- Minimizes energy usage through optimized membrane technology.

- Adapts to diverse aromatic vapors for flexible application across operations.

- Applications

- Xylene, Hydrocarbons, Aromatic compounds, Benzene, Terminals, Petrochemicals, Product vapours, Emission control, Refineries, Toluene

- End products

- Petrochemical derivatives, Xylene solvents, Aromatic solvents, Toluene-based additives, Benzene-based chemicals, Refined hydrocarbons, Vaporized emissions control products

- Steps before

- Petrochemical extraction, Aromatic vapour generation, Refinery processing

- Steps after

- Emission control, Product recovery, Environmental compliance monitoring

- Input ingredients

- aromatic vapour streams, benzene, toluene, xylene

- Output ingredients

- treated aromatic vapour streams, emission controlled vapours, recovered aromatics, < 1mg benzene/m³

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Emission Control Efficiency

- , lt

- 1mg benzene/m³

- Process Stability

- Longest lifetime stability

- Adsorbent Material Saturation

- No saturation

- Safety Maintenance

- No contamination of process fluids/materials

- Technology References

- Proven superior technology

- Emission control efficiency

- < 1mg benzene/m³

- Process flexibility

- Flexible aromatic vapour treatment

- Maintenance method

- Safe maintenance, no contamination

- Operation longevity

- Longest lifetime stability and efficiency

- Corrosive resistance (e.g. acids)

- Aromatics and petrochemical contaminants

- Cleanability

- Easy to maintain and clean due to design

- Abrasion resistance

- Durable against process wear and tear

- Biological compatibility

- Not applicable

- Process Type

- Membrane process with additional unit operations

- Emission Limits Compliance

- < 1mg benzene/m³

- Emission Level Compliance

- Strict worldwide limits

- Material Treatment

- Aromatic product vapours

- Maintenance Safety

- No contamination of process fluids/materials

- Membrane Process

- Superior technology