Co2 utilization and sequestration system

Optimize CO2 emissions management by converting captured CO2 into valuable products such as methanol, carbonates, and liquid food-grade CO2, integrating seamlessly with existing operations to enhance sustainability and efficiency in chemical processing environments.

Liquefies and Purifies CO2 for Industrial Applications

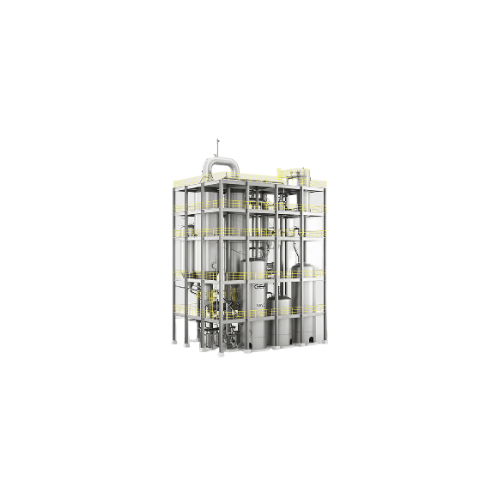

The GEA NAVO CO2 Utilization and Sequestration System is designed to streamline the transformation of gaseous CO2 into a high-purity liquid state. This system stands out for its robust liquefaction and purification capabilities, leveraging a multi-phase processing approach to ensure optimal CO2 quality for industrial utilization. Ideal for chemical processing industries, energy companies, and environmental solution providers, it supports applications ranging from methanol synthesis to carbonate production. The system handles the continuous liquefaction, purification, and conditioning of CO2, integrating seamlessly into existing production lines with PLC-controlled automation and remote monitoring features. Its energy efficiency is further enhanced by the inclusion of waste-heat recovery units, optimizing operational costs. Available in corrosion-resistant materials, it complies with stringent industrial standards, ensuring extended service life and reliability. Maintenance is simplified through an integrated CIP system, promoting operational hygiene and reducing downtime. Customization options allow for tailored processing capacities and configurations to meet specific customer needs.

Benefits

- Enhances operational efficiency with continuous CO2 liquefaction and purification.

- Lowers energy costs through integrated waste-heat recovery.

- Ensures high product quality and compliance with industry standards.

- Minimizes maintenance time with an integrated CIP system.

- Adapts to specific production needs with customizable configurations.

- Applications

- Chemical building blocks, Methanol, Liquid food grade co2, Carbonates, Carbon capture solutions, Value-added products

- End products

- Carbonated beverages, Formaldehyde, Polyurethane foam, Foam insulation, Tetrahydrofuran, Dichloromethane, Acetic acid, Polypropylene carbonate, Olefins, Dry ice, Urea, Solvay soda ash, Sodium carbonate, Calcium carbonate, Potassium carbonate

- Steps before

- CO2 Capture, Purification, Compression, Cooling, H2 Production

- Steps after

- Methanol Synthesis, Methanol Upgrading, Carbonate Production, Storage, Distribution

- Input ingredients

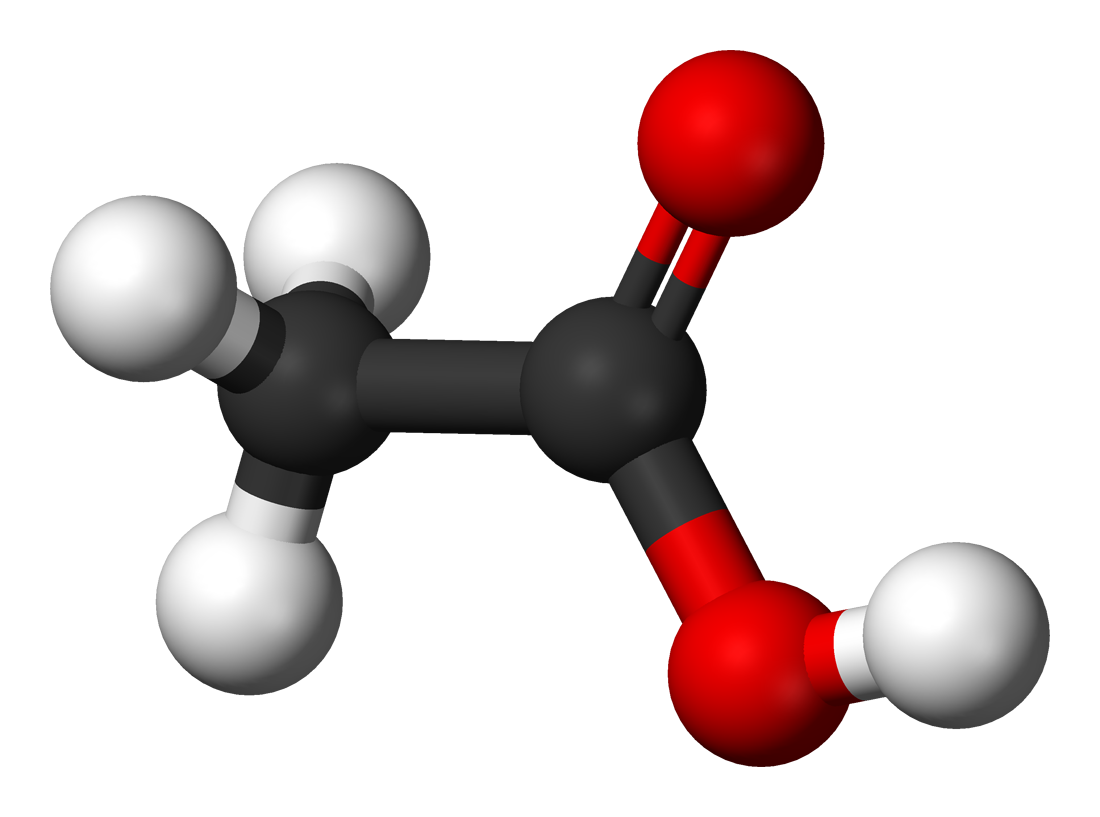

- gaseous CO2, hydrogen

- Output ingredients

- liquid CO2, methanol, carbonates

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- CO2 Purification

- Food grade

- CO2 Compression

- Thermal energy reintegration

- Methanol Production Capacity

- Industrial-scale

- CO2 Liquefaction

- Liquid food grade CO2

- CO2 Storage

- Rail/Truck/Pipeline delivery

- Carbonate Production Capacity

- Several 100 tons per day

- Waste Heat Recovery

- Integrated in Carbon Capture Unit

- Carbon Capture System

- Amine-based

- Gas Pre-Treatment

- Includes cooling, condensing, and removal of impurities

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Intermediary Storage Facility

- Available for partial loads

- Methanol Production

- From CO2 and H2

- Collection and Delivery System

- Rail/Truck or Pipeline