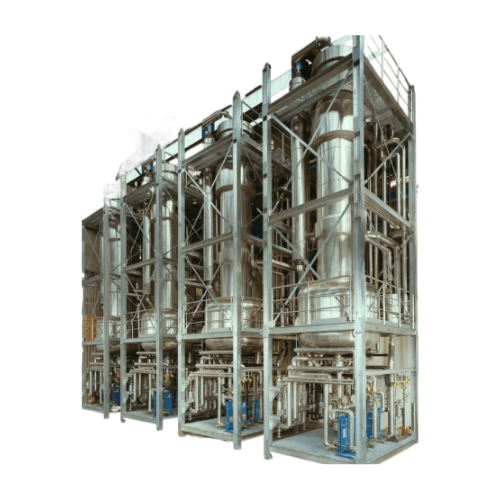

Batch distillation plants for diverse compound mixtures

Optimize your separation processes with flexible batch distillation, ideal for handling variable and complex liquid mixtures across continuous production requirements.

Separates and Purifies Diverse Liquid Mixtures

The Batch Distillation Plants from GEA are designed to efficiently manage the distillation of complex liquid mixtures in pharmaceutical, chemical, and wastewater treatment industries. These plants specialize in separation and purification by utilizing batch processing with flexible reflux ratios, adapting to both fixed and varying distillate concentrations. Ideal for small to medium-scale operations, they are primarily used for solvent recovery, production of active pharmaceutical ingredients, and purification of high-value oils. With integration capabilities, these plants feature PLC-controlled systems providing operational precision and reduced energy consumption. Constructed from high-grade materials for corrosion resistance, GEA’s plants comply with industry standards, ensuring optimal safety and performance. Additionally, their modular design facilitates cleaning and maintenance, while offering customization options tailored to specific process requirements.

Benefits

- Enhances operational flexibility with adaptable batch processing for varied mixture types.

- Lowers energy consumption using efficient reflux control systems.

- Complies with industry regulations, ensuring safe and reliable pharmaceutical production.

- Minimizes production downtime with robust, corrosion-resistant construction.

- Optimizes resource recovery, reducing waste in solvent and water purification processes.

- Applications

- High-value oils, Solvent recovery, Wastewater treatment, Pharmaceuticals

- End products

- Purified wastewater, Active pharmaceutical ingredients, Recovered ethanol, Essential oils

- Steps before

- Solvent Recovery, Boiling, Heating

- Steps after

- Purification, Fractionation, Condensation

- Input ingredients

- diverse products, multiple component mixtures, small scale solvent, wastewater, high valuable oils

- Output ingredients

- fractionated components, purified solvents, constant distillate concentration, purified oils

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Batch size

- Small to medium

- Capacity

- Small and medium-sized capacities

- Boiling range

- Defined based on components' boiling points

- Reflux ratio

- Fixed or varying

- Distillation type

- Batch and rectification

- Distillation process

- Multi-component fractionation

- Distillate concentration

- Constant (varying reflux ratio)

- Heat source

- MVR / TVR heating

- Energy efficiency

- Batch less efficient than continuous

- Product applications

- Pharmaceuticals, solvent recovery, valuable oil purification, wastewater treatment

- Operation mode

- Batch

- Reflex ratio control

- Fixed / Varying

- Production capacity

- Small / Medium

- Flexibility

- Multi-component mixtures

- Application industry

- Pharmaceutical, Oil, Wastewater

- Energy efficiency compared to Continuous

- Lower

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Yes/No

- Viscosity

- Low/Medium/High

- Foaming tendency

- Low/Moderate/High

- Container size

- Small/Medium/Large

- Boiling point range

- 60–300°C

- Solvent recovery

- Yes/No

- Corrosion resistance

- Yes/No

- Batch size

- Small to medium capacities

- Operation mode

- Fixed or varying reflux ratio

- Operational flexibility

- Multi-product separations

- Integration possibilities

- With dehydration, purification