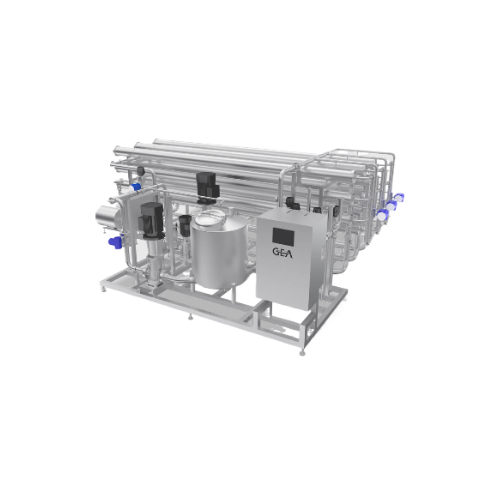

Condensate polisher for industrial water reuse

Transform waste streams into high-quality water, ready for reuse in diverse industrial applications, with this advanced condensate polisher that features cutting-edge membrane filtration and reverse osmosis technology.

Purifies and Reclaims Water from Industrial Condensate

The Condensate Polisher from GEA Membrane Plants & Solutions is engineered to transform industrial waste streams into high-quality process water. Utilizing advanced reverse osmosis and membrane filtration technologies, it efficiently purifies condensate, making it ideal for dairy processing, chemical manufacturing, and beverage production. This unit operates continuously at high scales, integrating seamlessly into various production lines to reduce hydraulic loads on wastewater systems. Capable of cutting fresh water consumption by up to 90%, it supports both energy and environmental sustainability. Available with stainless steel constructions for enhanced corrosion resistance, it meets the rigorous standards of multiple industries while offering customization options to fit specific operational needs. Additionally, its design includes features such as a CIP system for easy maintenance and flexible throughput capabilities to match growing production demands.

Benefits

- Reduces fresh water usage by up to 90% through effective water recovery.

- Lowers operational costs with continuous, high-scale processing capabilities.

- Enhances product quality by ensuring low COD/BOD in purified water.

- Decreases waste disposal challenges by reusing treated water in production.

- Meets stringent industry standards with stainless steel options for maximum durability.

- Applications

- Marine, Gas and energy, Oil, Environment, Chemical, Food and beverage, Dairy

- End products

- Clean water for environmental discharge, Boiler feed water, Reclaimed water for beverage production, Purified water for dairy processing, Process water for marine applications, Recycled water for oil refining processes, Treated water for gas processing operations, Demineralized water for chemical processes

- Steps before

- Evaporation, Condensation

- Steps after

- Re-use as process water, Cooling, Rinsing, Discharge into drainage ditch

- Input ingredients

- condensate from evaporation plants, impure process water, condensate containing impurities, waste stream, condensate with chemical oxygen demands (COD), condensate with ions, condensate with unwanted components

- Output ingredients

- high quality purified water, process water, cooling water, rinsing water, discharged water, filtrate with low COD/BOD, regained water, CIP flush water, CIP water, water for hose stations, pump seal water, boiler water

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Purification Method

- Reverse osmosis

- Operating Pressure

- Depends on condensate quality

- Condensate Quality

- High-grade process water

- Cod / BOD Level

- Low

- Ion Content

- Low

- Conductivity Level

- Low

- Capacity Adjustment

- Hydraulic load reduction up to factor five

- Water Recovery Rate

- Up to 90%

- Membrane Filtration Type

- Microfiltration / Ultrafiltration / Nanofiltration / Reverse Osmosis

- System Type

- Membrane filtration plant

- Working mechanism

- Membrane filtration / Reverse osmosis

- Integrated steps

- Condensate purification

- Batch vs. continuous operation

- Inline continuous

- CIP principles

- CIP systems available

- Automation level

- PLC / SCADA

- Cleaning method

- CIP / Manual

- Energy efficiency

- High due to condensate recovery

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Condensate Type

- Dairy and food evaporation plants

- Discharge method

- Direct discharge

- Control panel type

- PLC

- Operating pressure

- Depends on condensate quality and purification level

- Process design

- Customized based on specific application requirements