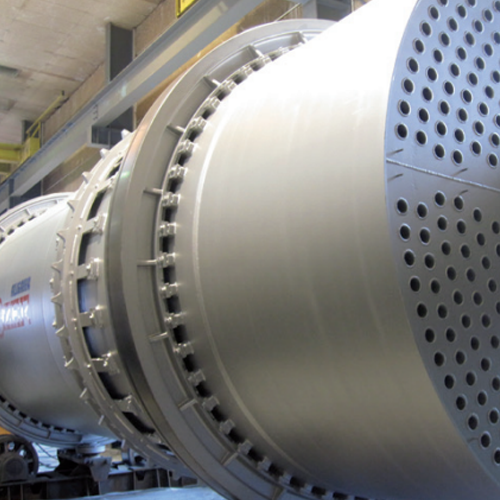

Indirect cooling drums for process heat recovery

Optimize your production by effectively cooling hot solids while recapturing valuable heat energy, ensuring reduced energy costs and enhanced sustainability throughout your processes.

Cools and Recovers Heat from Hot Solids

The Indirect Cooling Drums from Allgaier Process Technology offer robust solutions for cooling hot solids while effectively recovering thermal energy. Ideal for industries including mining, chemicals, and waste processing, these drums utilize an indirect rotary design where hot material is cooled by air passing through separated chambers. This eliminates direct contact, enhancing the efficiency of heat transfer and enabling energy conservation. Suited for applications such as titanium pigment production and gypsum plasterboard manufacturing, the equipment handles diverse materials from powders to granules.

These cooling drums are continuous-operation machines, ensuring consistent throughput and integrating seamlessly into existing lines. The design minimizes energy consumption by utilizing preheated, dry exhaust air, reducing both operational costs and environmental impact. Constructed with durable materials, the drums are engineered for long-term performance and minimal maintenance. Customization options are available to adapt the drums for specific processing needs, supported by Allgaier’s engineering expertise.

Benefits

- Minimizes process costs by using recovered heat, reducing primary energy needs.

- Robust design ensures longevity and reliable performance in demanding industrial environments.

- Facilitates sustainable operations by conserving natural resources and reducing emissions.

- Enhances production efficiency through rapid heat transfer and temperature control.

- Integrates seamlessly into existing continuous production lines, optimizing workflow.

- Applications

- Titanium dioxide, Bulk materials, Calcined gypsum, Powdery products, Mineral raw materials, Granular products

- End products

- Titanium pigments, Mineral powders, Gypsum plasterboards, Granules for fertilizers, Pigment dispersions, Ceramic powders, Cement additives, Granular feedstock for plastics

- Steps before

- Calcining, Heating

- Steps after

- Further processing, Storage, Packaging

- Input ingredients

- hot solids, calcined solids, bulk materials, titanium dioxide, calcined gypsum, powdery products, granular products

- Output ingredients

- cooled solids, heat energy recovery, preheated cooler exhaust air, dust-free cooler exhaust air, dry cooler exhaust air

- Market info

- Allgaier Process Technology is known for manufacturing advanced screening, drying, cooling, and sorting equipment for various industries, specializing in custom-engineered solutions and innovative designs to enhance efficiency and productivity.

- Heat Recovery

- Effective recovery

- Cooling Type

- Indirect

- Cooling Medium

- Air

- Design Type

- Robust and durable

- Temperature Compatibility

- High temperature

- Contact Type

- Non-contact

- Drum Type

- Rotary

- Sustainability

- Environmentally friendly

- Efficiency

- High efficiency

- Material Compatibility

- Powdery or granular

- Working mechanism

- Indirect cooling with heat recovery

- Integrated steps

- Cooling and energy recovery

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- High

- Changeover time

- Minimal

- Robust design

- Durable and environmentally friendly

- Abrasive materials

- Yes

- Chemical resistance

- Titanium Dioxide, Gypsum

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- High

- Density/particle size

- Variable

- Bulk materials suitability

- Powdery or granular

- Discharge method

- Indirect

- Machine footprint

- Compact

- Control panel type

- Integrated

- Control panel type

- PLC-controlled

- Integration possibilities

- Compatible with existing systems

- Cooling method

- Indirect cooling via air separation wall

- Customization options for heat recovery

- Adjustable thermal energy recovery