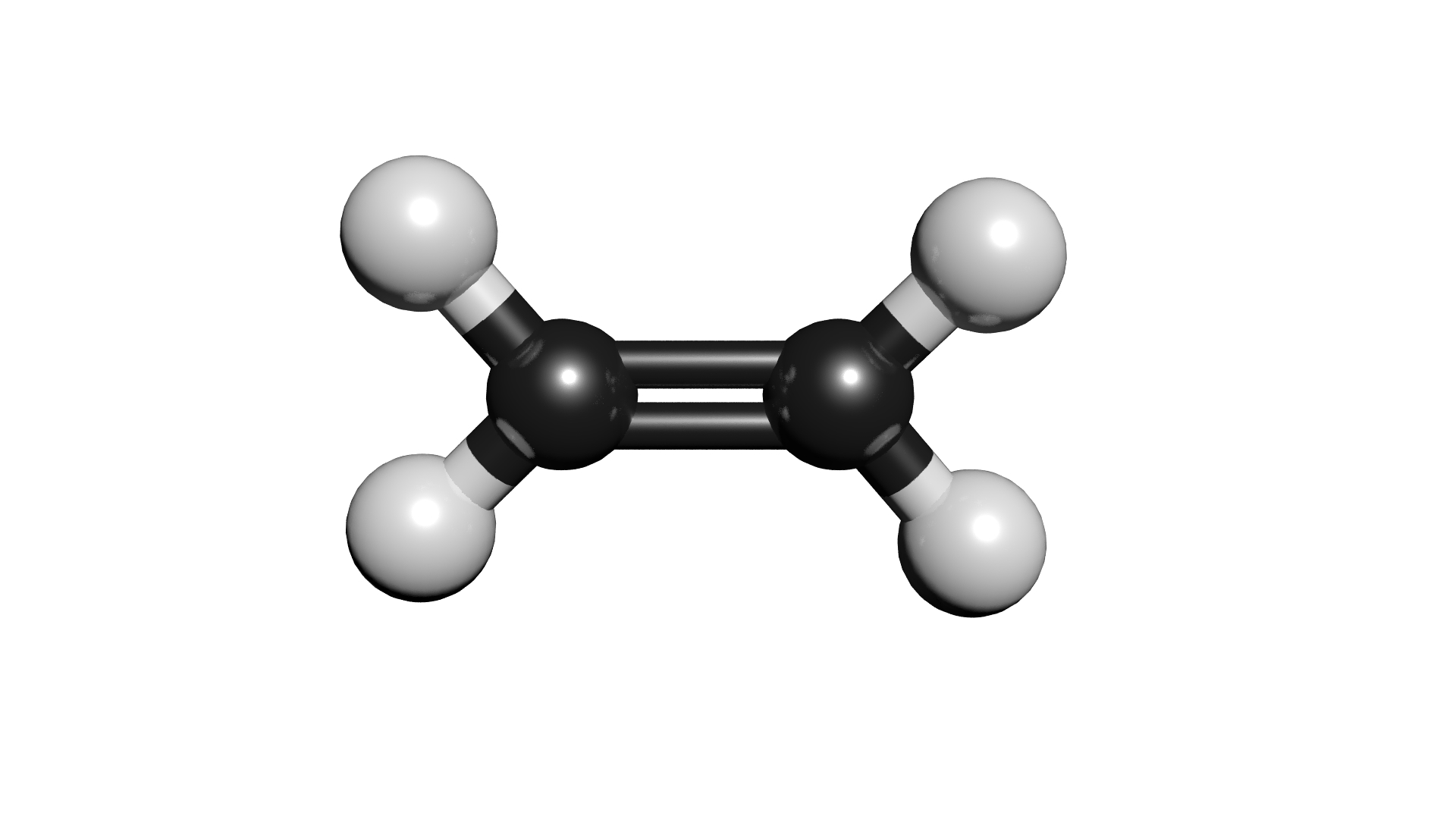

Ethylene recovery unit for ethylene oxide and glycol production

Recover valuable ethylene monomer efficiently from cycle gas purge with this unit, ensuring reduced waste and optimized resource utilization in your production line.

Separates Ethylene from Purge Gases

The BORSIG Ethylene Recovery Unit for EO/EG Production efficiently captures ethylene from cycle gas purge streams, improving resource recovery in petrochemical and chemical operations. This unit employs a hydrocarbon-selective membrane stage, separating ethylene from argon and nitrogen. With its compact package unit design, it offers quick installation and seamless integration into existing systems. Common applications include the production of ethylene oxide, ethylene glycol, and other monomers. The unit ensures safe operation, high reliability, and low maintenance requirements, making it ideal for continuous, automated high-speed operations. With reference installations across various licensors, it promises a quick return on investment by optimizing process efficiency and reducing waste.

Benefits

- Increases ethylene yield by optimizing separation efficiency, enhancing production profitability.

- Minimizes installation time and complexity with pre-engineered package unit design.

- Enhances operational reliability and lowers maintenance costs, ensuring consistent production.

- Provides a fast return on investment by reducing ethylene losses in purge streams.

- Seamlessly integrates with existing systems, supporting continuous and automated production processes.

- Applications

- Propylene, Hydrocarbons, Monomers, Ethylene, Nitrogen, Seal gases

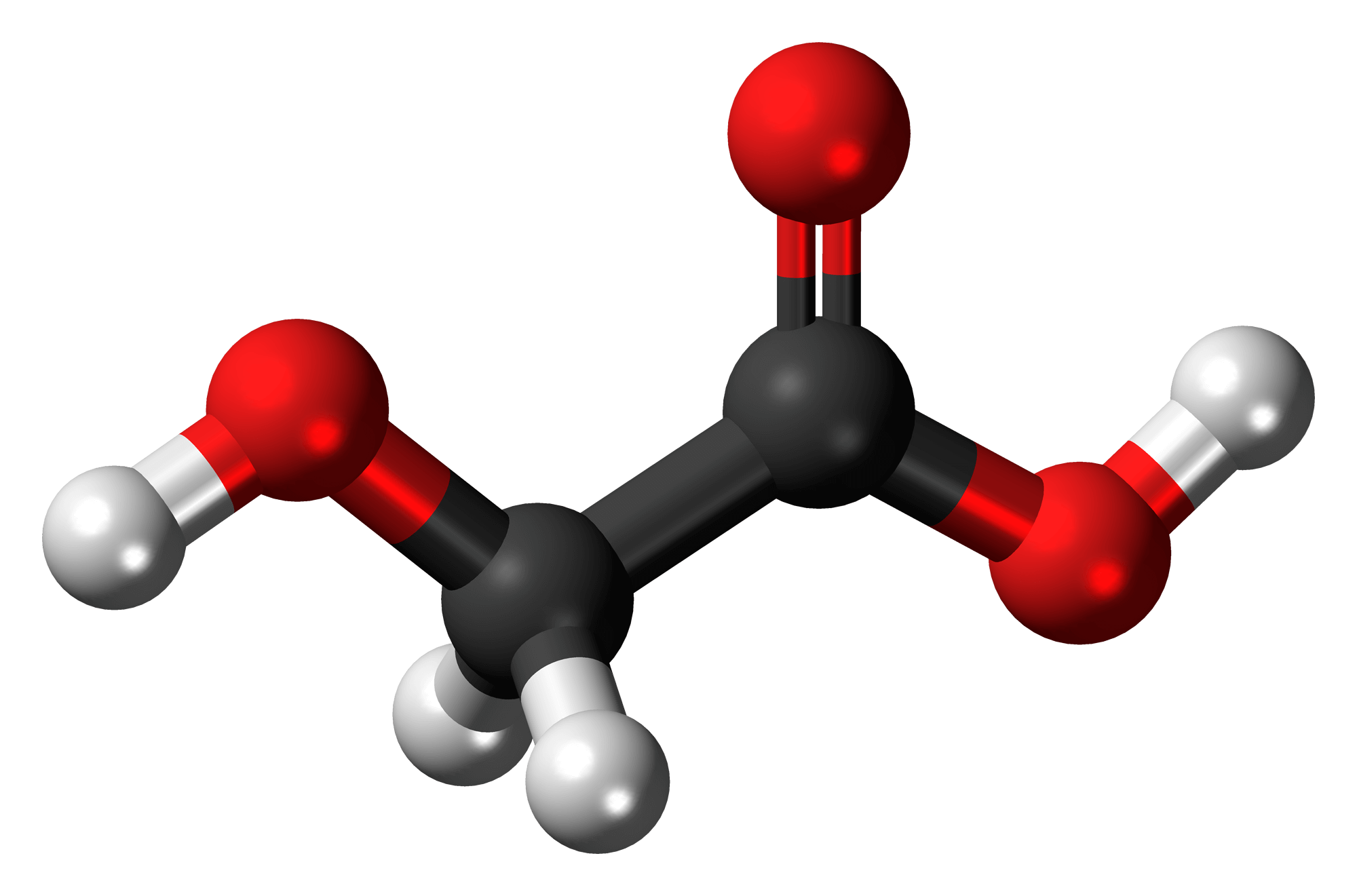

- End products

- Polyethylene, Polypropylene, Styrene monomers, Polycarbonates, Ethylene glycol, Nitrogen-based fertilizers, Synthetic rubber, Acrylonitrile, Industrial sealants, Ethylene oxide

- Steps before

- Inlet filtration, Droplet removal, Purging gas cycle

- Steps after

- Compression, Boiler routing

- Input ingredients

- cycle gas purge, argon, nitrogen

- Output ingredients

- ethylene-rich stream, ethylene-depleted stream, ethylene monomer

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Recovery rate

- High

- Installation time

- Quick

- Membrane selectivity

- Hydrocarbon-selective

- Operation safety

- High reliability

- Maintenance requirement

- Low

- Working mechanism

- Hydrocarbon-selective membrane stage

- Integrated steps

- Inlet filter for droplet removal

- Automation level

- Manual / PLC-controlled

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- High recovery rate

- Changeover time

- Quick

- CIP/SIP

- Not specified

- Cleaning method

- Not specified

- Safety and reliability

- Safe operation, high reliability

- Maintenance requirements

- Low maintenance

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact, modular design

- Shape

- Membrane module shape

- Size

- Customizable package size for easy integration

- Feed/Discharge Method

- Inlet filter method

- Construction Material

- Corrosion-resistant materials

- Control panel type

- Advanced HMI integration

- Package unit design

- Quick installation, easy implementation

- Integration possibilities

- High compatibility with existing systems