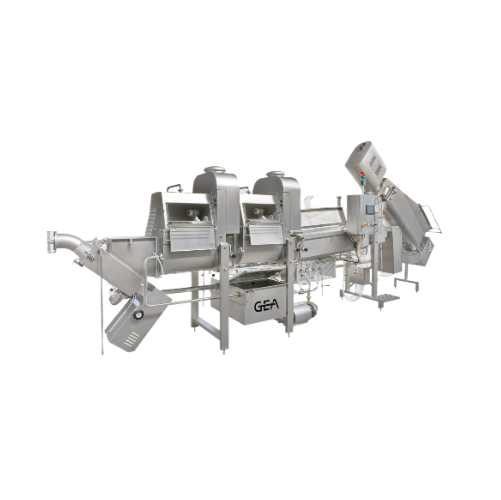

Steam stretching system for pasta filata cheese

Optimize your cheese production with a system that seamlessly integrates steam stretching, improving yield while reducing energy and water consumption in your pasta filata processing line.

Incorporates Steam into Pasta Filata Cheese

The Steam Stretching Machines – Continuous Type from GEA revolutionize pasta filata cheese production by integrating steam directly into the cheese, eliminating water-based by-products. Designed for medium- to large-scale operations, these continuous machines handle up to 6,000 kg/h, perfect for producing fresh mozzarella, scamorza, and pizza cheese. The system features robust rotary paddles for efficient pre-stretching and mixing. It offers significant energy savings—up to 30%—while increasing yields by 1% compared to traditional methods. With PLC-controlled operations, it ensures precise temperature regulation and recipe storage. Crafted from AISI 304 stainless steel and enhanced with the patented Vulcan non-stick treatment, this equipment supports CIP systems and complies with stringent hygiene standards, offering durability and ease of maintenance.

Benefits

- Enhances yield and product quality by seamlessly incorporating steam into cheese processing.

- Achieves up to 30% energy savings, reducing operational costs.

- Virtually eliminates by-products like stretching water and whey, simplifying waste management.

- Ensures precise production parameters with PLC-controlled temperature and process management.

- Provides durable performance with Vulcan-treated surfaces, minimizing maintenance requirements.

- Applications

- Fresh mozzarella, Caciocavallo, Pizza cheese, Cheese products, Pasta filata cheese, Scamorza

- End products

- Scamorza affumicata, Mozzarella cheese braid, Pizza mozzarella blocks, Fresh mozzarella balls, Caciocavallo silano, Cheese loaves for pizzerias

- Steps before

- Milk processing, Curd cutting, Pre-stretching

- Steps after

- Molding, Cooling, Packing

- Input ingredients

- milk, commercial curds, mixtures of milk and curds

- Output ingredients

- pasta filata cheese, fresh mozzarella, braids, loaves for pizzerias, scamorza, caciocavallo, pizza-cheese

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 500–6, 000 kg/h

- Feed Rate

- 1, 000–6, 000 kg/h

- Automation

- PLC-controlled

- Energy Savings

- 30%

- Dimensional Material

- Stainless Steel AISI 304

- Surface Treatment

- Teflon/Vulcan non-stick technology

- Steam Injection Points

- Multiple

- Temperature Control

- Automatic pneumatic valves

- Mixing Components

- Dipping arms/Rotary paddles

- Additional Features

- Double-walled feeding tunnels

- Operator Safety

- Electromechanical protection, electromagnetic sensors

- Cleaning System

- Automatic CIP

- Working Mechanism

- Continuous

- Integrated Steps

- Pre-stretching, steam injection

- Automation Level

- PLC-controlled

- CIP/SIP

- CIP capable

- Energy Efficiency

- Energy savings up to 30%

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- CIP

- Cleanability

- Compatible with CIP (Cleaning In Place)

- Corrosive resistance (e.g. acids)

- Stainless steel AISI 304

- Vulcan-treated surfaces

- Abrasion resistance

- Vulcan-treated surfaces

- Biological compatibility

- Suitable for food-grade applications

- Cheese types produced

- Mozzarella, Scamorza, Caciocavallo, etc.

- Machine footprint

- Designed for medium to large-scale production

- Steam stretching setup

- Double-walled feeding tunnels, rotary paddles, counter-rotating augers

- Construction material

- Stainless steel AISI 304

- Non-stick surface treatment

- GEA's Vulcan technology

- Feeder type

- Double-walled feeding tunnel with dipping arms

- Capacity

- 500 kg/h to 6, 000 kg/h

- Surface treatment

- Vulcan technology or Teflon coating

- Mechanical structure

- Robust rotary paddles

- Control system

- PLC-controlled

- Safety features

- Mechanical and electromechanical protection with electromagnetic sensors

- Feeding mechanism

- Counter-rotating augers

- Heating method

- Steam injection, optional hot water

- Discharge method

- Continuous discharge

- Control Software

- PLC-operated with recipe storage

- Non-stick Surface Treatment

- GEA Vulcan Technology

- Steam,Hot Water Combination

- Yes

- Feeding Tunnel Type

- Double-walled with counter-rotating augers

- Molding Integration

- Drum molding, molding units, special molding machines

- Rotary Paddle Dimensions

- Various dimensions

- Mechanical Protection

- Electromechanical with electromagnetic sensors

- Cleaning System

- Fully automatic CIP

- Remote Assistance

- Available for PLC-operated machines

- Recipe Storage Capacity

- Up to ten recipes

- Valve Control

- Automatic pneumatic and manual micrometric valves

- Steam Injection Points

- Multiple, in feeding tunnel and mixing vat