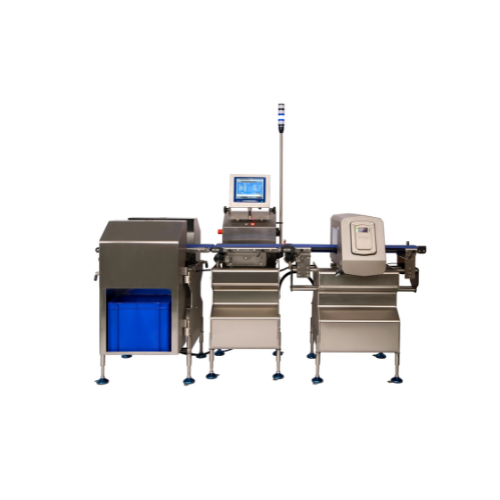

Checkweigher for food processing compliance

Ensure accurate package weights while preventing underweight or overweight products with this high-precision checkweighing solution, ideal for maintaining compliance with weight standards across diverse food processing operations.

Monitors, Weighs, and Rejects Inconsistent Food Packages

The MCheck 2 Checkweigher from Marel efficiently addresses the demands of high-speed, continuous food processing environments. It uses precise dynamic weighing technology to seamlessly monitor, weigh, and reject packages that deviate from specified weight parameters. Intelligent integration with Marel’s Innova software provides real-time data monitoring and analysis, optimizing your line’s productivity by feeding forward accurate weight information, thus reducing product giveaway.

Ideal for applications across poultry, meat, fish, and prepared foods industries, the MCheck 2 processes items ranging from whole chicken packs to plant-based nuggets. Its robust design supports full washdown to IP69 standards, ensuring hygiene and food safety with optional metal detection capabilities.

With a throughput of up to 150 packs per minute and the ability to process weights from 40g to 6,000g, the MCheck 2 offers versatile performance. The machine’s modular design allows for customizable configurations and features stainless steel construction for corrosion resistance. Fully compliant with weight legislation and capable of remote access, it provides peace of mind through stringent quality control and easy maintenance.

Benefits

- Enhances product quality by preventing non-compliance with weight specifications.

- Improves operational efficiency with real-time weight monitoring and reporting.

- Increases line accuracy by integrating with dosing systems for precise weight control.

- Ensures longevity and hygiene with IP69 standard washdown capabilities.

- Strengthens food safety through optional multi-frequency metal detection.

- Applications

- Cheese, Fruit and vegetables, Salmon, Fish, Broilers, Turkey, Pig / pork, Duck, Pet food, Convenience products, Plant-based products, Cattle / beef, Sausages, Potato specialties, Meat, Whitefish, Poultry, Prepared foods, Other seafood

- End products

- Duck confit, Chicken drumsticks, Salmon portions, Hot dogs, Whole chicken packs, Potato croquettes, Cod fillets, Packaged lettuce, Chicken breast fillets, Pork chops, Beef brisket, Kibble, Canned tuna, Fish fillets, Turkey wings, Veggie burgers, Tilapia fillets, Turkey breast fillets, Mozzarella slices, Cheddar cubes, Plant-based nuggets, Bratwurst sausages, Crab cakes, Pet treats, Sliced watermelon, Duck breast, Pork loins, Beef steaks

- Steps before

- Weighing, Sorting, Grading, Batching, Inspection

- Steps after

- Packing, Labeling, Metal Detection, Reject Handling, Traceability

- Input ingredients

- indexed packs, pieces, various pack sizes, metal contaminated packs

- Output ingredients

- weighed packs, compliant sealed packs, checked weights, accurate package weights, underweight/overweight rejected packs

- Market info

- Marel is known for its advanced food processing equipment, specializing in systems and services for poultry, meat, and fish industries. It is recognized for innovation, quality, and improving processing efficiency and sustainability.

- Throughput

- up to 150 packs/min

- Belt speed

- up to 80 m/min

- Standard weighing configurations

- 40 - 1, 000 g by 0.5 g / 80 - 3, 000 g by 1.0 g / 160 - 6, 000 g by 2.0 g

- Pack size (Length)

- 80 mm - 589 mm

- Pack size (Width)

- 50 mm - 350 mm

- Pack size (Height)

- 10 mm - 125 mm

- Power requirements

- 110/230V +/-10% 50-60 Hz, 1ph, 8A/4A

- Compressed air requirements

- 1.25 l/min at 0.6 MPa

- Net weight

- 120 kg

- Environment Temperature

- 0–35°C

- Environment Humidity

- 40–60%

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- Line optimization

- Yield calculation and efficient dosing

- Cleaning method

- Full washdown to IP69 standards

- Compliance with weight legislation

- Ensures correct package weight

- Food safety and hygiene

- Metal detection and reject options

- Modular configurations

- Multiple reject options and metal detection

- Optional features

- Trend light indicator

- Cleanability

- Full washdown to IP69 standards

- Corrosive resistance (e.g. acids)

- High

- Biological compatibility

- Food safe

- Density/particle size

- 0.5 g to 6, 000 g

- Measuring instrument directive

- 2004/22/ED

- IP69

- Full washdown standard

- Modular configurations

- Available

- Control panel type

- Remote access and display option

- Modular configurations

- Available in different modular configurations

- Reject method

- Single pusher, flipper, twin reverse flipper or drop flap

- Metal detection

- Single and multi-frequency options