High-speed paddle mixer for food industry blends

Achieve rapid, high-energy blending of varied particulate materials with precision and speed, ensuring consistent product quality while efficiently breaking down agglomerations to streamline your processing operations.

Mixes and Blends High Consistency Materials

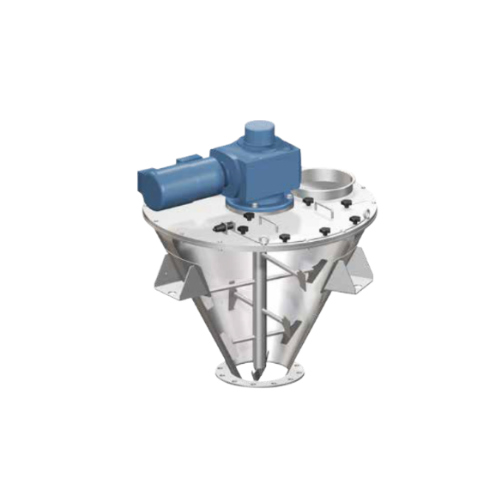

The Paddle Mixer ZSD from Zeppelin Systems is designed for high-speed blending and agitation, catering to the demands of the food, plastics, and chemical industries. This upright cylindrical mixer features a conical outlet and an agitator shaft with welded paddles positioned near the wall, enabling efficient breaking down of agglomerations. With its gear motor-driven mechanism, the mixer facilitates intensive mixing of powders and granules, achieving uniform consistency in products like cheese powder, rubber compounds, and paint emulsions.

Ideal for batch processes, the ZSD operates at high speeds with upward-facing paddles creating rapid vertical cycles of product movement, while maintaining a safe, shaft-seal-free design. It offers easy cleaning and inspection through a top access door equipped with a safety limit switch. Integration into existing production lines is seamless with the conical outlet’s connecting flange adaptable for various downstream units. Additionally, the Paddle Mixer ZSD provides energy-efficient operation by reducing speed during filling and emptying phases, ensuring reliable and quick mixing of even small component additions.

Benefits

- Ensures consistent product quality with rapid, high-energy mixing.

- Reduces operational costs by minimizing maintenance with a shaft-seal-free design.

- Facilitates seamless integration into existing production lines with adaptable discharge connectivity.

- Enhances process efficiency by automatically adjusting speeds during different operations.

- Minimizes contamination risk with easy cleaning and inspection access.

- Applications

- Mixing and compounding, Food industry, Chemical industry, Plastics, Rubber and tire industry, Dispersion paints

- End products

- Polyethylene pellets, Rubber compounds, Powder coatings, Automotive tire treads, Paint emulsions, Confectionery coating, Latex-based adhesives, Pvc pipes, Cheese powder

- Steps before

- Gravimetric Filling, Pneumatic Filling, Material Charging

- Steps after

- Discharge, Downstream Processing, Packaging

- Input ingredients

- various ingredients, small ingredients, bulk materials, powder, granules

- Output ingredients

- homogeneous blend, agglomeration-free mixture

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Mixing vessel orientation

- Upright cylindrical

- Outlet type

- Conical

- Drive type

- Gear motor

- Shaft mounting

- Top-mounted

- Paddle movement

- Interlocking, upward-facing

- Mixing speed

- High speeds

- Automation

- Safety limit switch for door

- Filling method

- Gravimetric or pneumatic

- Cleaning access

- Inspection and maintenance door

- Product discharge

- Full via conical outlet

- Mixing speed

- High speed

- Mixing type

- Intensive, rapid mixing

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / PLC-controlled

- Cleaning method

- Manual

- Inspection and maintenance

- Inspection door with safety switch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Upright cylindrical

- Design

- Upright cylindrical mixing vessel with conical outlet

- Agitator shaft position

- Center with welded paddles

- Agitator support

- Mounted at the top

- Discharge method

- Conical outlet with connecting flange

- Access

- Inspection and maintenance door on the cover

- Filling method

- Gravimetric or pneumatic via connecting nozzles

- Safety feature

- Safety limit switch on door

- Control panel type

- PLC / HMI interface

- Integration possibilities

- Modular installation

- Shaft mounting

- Top-mounted

- Supporting brackets

- For frame installation

- Connecting nozzles

- Gravimetric or pneumatic filling

- Discharge method

- Conical outlet with flange

- Inspection door

- Safety limit switch equipped