Draining matting solution for granular or matted curd cheese

Optimize your cheese production with a continuous, automated solution that efficiently handles curd processing, from draining to whey removal, ensuring high yield with minimal fat and fines loss. Ideal for producing a variety of cheeses, it offers flexibility and precision for diverse cheese consistency and moisture levels.

Processes and Transports Cheese Curds Continuously

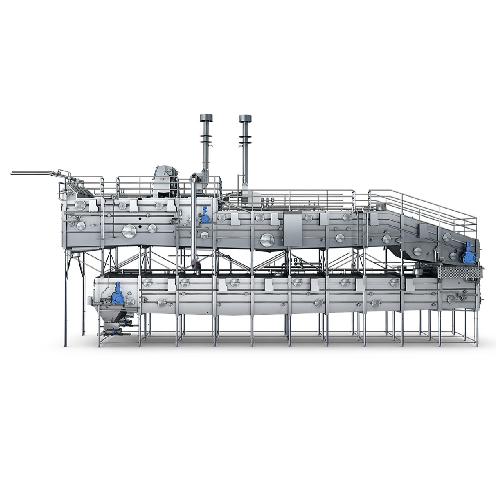

The Tetra Pak® Draining Matting Machine 2 is a cornerstone in the Tetra Pak cheese production lineup, designed for continuous, automated processing of cheese curds. This machine stands out with its ability to handle curds gently, minimizing loss of fat and fines, while offering the flexibility to produce both matted and granular curds. Ideal for a range of end-products such as Cheddar, Colby, and Monterey Jack cheeses, it includes optional features for pre-salting and washing curds, tailored to specific cheese varieties.

The machine’s working principle involves an enclosed conveyor system that facilitates efficient whey removal through a specially designed wedge wire screen, ensuring high yield and minimal fines generation. It integrates seamlessly into production lines, supporting continuous operations with its CIP isolation device that allows upper belt cleaning without halting production. Made with durable materials, this solution ensures longevity and reduced maintenance requirements. Specifically engineered for the US market, it offers dairy producers and cheese manufacturers a customizable solution backed by decades of Tetra Pak’s engineering expertise.

Benefits

- Maximizes yield by minimizing fat and fines loss during curd processing.

- Offers flexibility to switch between matted and granular curd types, accommodating diverse cheese recipes.

- Enhances production efficiency with CIP isolation, allowing cleaning without stopping the line.

- Reduces cleaning time and maintenance with self-tensioning, self-tracking belts.

- Ensures efficient whey removal to produce high-quality, low-moisture cheese.

- Applications

- Matted cheese, Monterey jack cheese, Cheese curds, Cheese, Colby cheese, Granular cheese, Dairy products

- End products

- Washed curd cheese, Colby cheese slices, Low moisture part-skim mozzarella, Matted ricotta, Granular feta, Cheddar cheese, Monterey jack blocks, Cheese curds snacks

- Steps before

- Milk curdling, Curd cutting, Heating curd, Curd transferring

- Steps after

- Cheese pressing, Aging, Packaging, Cooling

- Input ingredients

- curd, granular curd, matted curd

- Output ingredients

- Colby cheese, Monterey Jack cheese, low moisture cheese, higher moisture cheese

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Curd Feeding System

- In-feed header system with two inlets

- Conveyor Type

- Curd conveyor for matted or granular curd

- Automation

- Continuous, automated operation

- Material of Construction

- Polypropylene for belt

- Whey Removal System

- Wedge wire screen with triangular cross-section

- Cleaning Method

- CIP isolation device for dual-belt cleaning

- Weir System

- Tipping weir with even distribution

- Batch vs. Continuous

- Continuous

- Automation level

- Continuous automated

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- CIP isolation for shorter cleaning time

- Flexibility

- Produce matted to granular curd

- Curd pre-salting and washing

- Multiple locations

- Handling method

- Gentle curd handling

- Abrasion resistance

- Self-tensioning belt

- Biological compatibility

- Food-grade materials

- Cleanability

- CIP-ready

- Corrosive resistance (e.g. acids)

- Polypropylene materials

- Density/particle size

- Handles various curd sizes

- Machine footprint

- Compact

- Feed method

- In-feed header system

- Discharge method

- Through tipping weir

- Shape

- Enclosed curd conveyor

- Curd washing devices

- Configurable according to need

- CIP isolation device

- Allows production to continue during cleaning

- Curd make variation

- From matted to granular curd

- Tipping weir programming

- User-specified intervals for curd clearing