Industrial slicer for sausage, ham, and cheese

Achieve precise and consistent slicing for meats and cheeses while minimizing waste with high-yield portion control, making it an ideal solution for enhancing product presentation and reducing production costs.

Slices and Portions Food Products Precisely

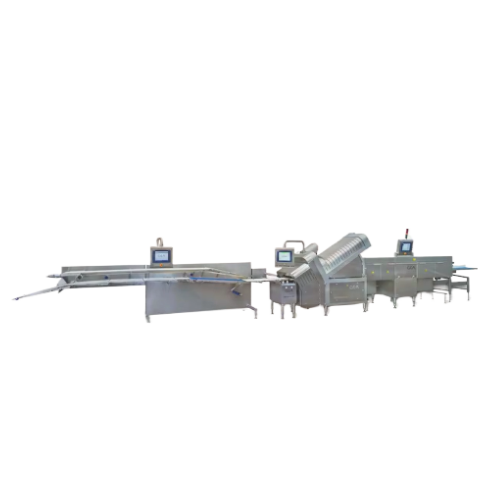

The GEA MegaSlicer XXL from GEA is an industrial involute blade slicer designed to enhance your food processing operations. This high-precision machine is engineered to tackle the complexities of slicing products such as cooked and raw ham, cheese, calibrated sausage, and salami. Utilizing a patented idle cut rotor technology, it ensures a consistent slice thickness and minimizes sliver slices, even at high speeds for soft products like boiled sausage.

Commonly integrated into fully automated production lines, the MegaSlicer XXL supports a range of applications, delivering end-products including neatly sliced bacon and perfectly portioned cheese slices. The machine’s automation features include automatic product loading and options for weighing, scanning, interleaving, and folding, making it versatile for various portion forms like shingle and zig-zag stacking.

Processing capacity is emphasized through its capability to handle products up to 1,830 mm in length with a maximum blade speed of 1,500 rpm. A PLC-controlled interface on a 15″ touch panel facilitates easy operation, recipe changeovers, and real-time monitoring, allowing for fast gripper, blade, and product adjustments. Designed with hygiene in mind, the MegaSlicer provides excellent access for cleaning, with tool-free removal of side panels for maintenance.

Customizable with various add-ons such as the GEA Check 4000 weighing system and the GEA OptiScanner, this slicer can be tailored to your specific production needs, helping to reduce material give-away and optimize yield. Available in stainless steel, it meets food safety compliance standards and supports long-term reliability in meat processing and dairy environments.

Benefits

- Enhances slicing precision and minimizes waste with involute blade technology.

- Integrates seamlessly into automated production lines, reducing manual intervention.

- Increases yield by maintaining consistent slice thickness and on-weight portions.

- Promotes hygiene and easy maintenance with tool-free access and design.

- Customizable options enhance versatility across diverse food processing applications.

- Applications

- Bacon, Calibrated sausage, Cheese, Cooked ham, Salami, Raw ham

- End products

- Cheese slices, Sliced salami, Sliced raw ham, Sliced cooked ham, Sliced calibrated sausage, Sliced bacon

- Steps before

- Loading, Pre-scanning, Density distribution analysis

- Steps after

- Weighing, Portion control, Interleaving, Folding, Packaging

- Input ingredients

- cooked ham, raw ham, cheese, calibrated sausage, salami, bacon, boiled sausage

- Output ingredients

- sliced cooked ham, sliced raw ham, sliced cheese, sliced calibrated sausage, sliced salami, sliced bacon, sliced boiled sausage, shingle portions, stack portions, zig-zag stack portions, shaved portions, contour shingle portions, folded portions, chunks, interleaved portions

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Type of blade

- Involute blade

- Blade sizes

- R 415 mm

- Max. blade speed

- 1, 500 rpm

- Cutting cross-section Width

- 365 - 428 mm

- Cutting cross-section Height

- 183 - 126 mm

- Max. product length

- 1, 180/ 1, 830 mm

- Product loading

- Automatic

- Power supply

- 15.5 kW

- Compressed air usage

- 6 bar 15NI/min

- Noise emission

- < 75 dB (A)

- Weight detection system

- Calibrated for loads between 20 and 5, 000 g

- Automation level

- Automatic product loading

- Cleaning method

- Easy and flexible operation with high hygiene

- Energy efficiency

- High yield with low energy consumption

- Changeover time

- Fast changeover of gripper, blade, and recipe

- Batch vs. continuous operation

- Continuous slicing process

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 1, 200 mm L x 1, 200 mm W (for 1, 200 mm product length) / 5, 225 mm L x 1, 200 mm W (for 1, 850 mm product length)

- Control panel type

- 15" touch panel

- Blade type

- Involute Blade

- Blade size

- R 415 mm

- Maximum blade speed

- 1, 500 rpm

- Product loading method

- Automatic

- Control panel type

- 15" touch panel

- Integration possibilities

- Fully automated line compatibility

- Blade size options

- R 415 mm, Ø 460 mm, Ø 480 mm

- Product loading

- Automatic

- Lane configuration

- Up to 4 lanes

- Interleaver

- Film or paper, Up to 3 lanes

- Weighing system

- GEA Check 4000

- Folding Unit

- Available

- Telemonitoring/Remote services

- GEA Performance Service