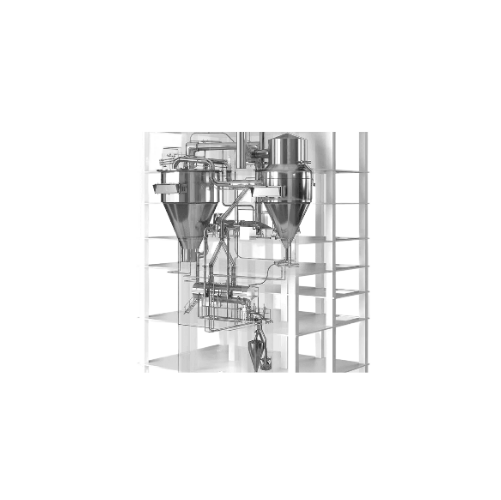

Spray dryer for agglomerated powders

Achieve uniform, coarse, and free-flowing agglomerated powders with precise drying and high efficiency. Ideal for transforming liquid feeds into stable product forms, this solution enhances your production line by integrating spray drying with fluid bed technology for optimal moisture control and particle quality.

Processes Liquids into Agglomerated Powders and Granules

The FSD® Spray Dryer from GEA combines spray drying with fluid bed technology to meet the demanding needs of food, chemical, and pharmaceutical powder production. This equipment excels in converting liquids into uniform, free-flowing powders through a multi-stage drying process involving atomization, high-velocity air mixing, and integrated fluid bed operation. Designed to process a wide range of products, it is ideal for applications like instant coffee granules, baby formula powder, and non-dairy creamers. With continuous and high-speed operations, it optimizes throughput while ensuring energy efficiency. The dryer integrates seamlessly into production lines, offering PLC control and easy integration with existing systems. Constructed with durable materials, it supports different configurations to accommodate specific industry needs and complies with major industry standards, promoting safe and efficient production. The optional FSD-GRANULATOR® enhances functionality with additional agglomeration capabilities.

Benefits

- Enhances product quality with uniform agglomeration and precise moisture control.

- Integrates seamlessly into continuous high-speed production lines, improving efficiency.

- Lowers operational costs through energy-efficient drying stages and reduced waste.

- Customizable configurations accommodate diverse processing needs across industries.

- Ensures operational safety and compliance with industry-standard materials and design.

- Applications

- Milk-powder, Chemical compounds, Whey powder, Nutritional formula, Food ingredients, Food products, Instant coffee, Dairy products

- End products

- Casein, Instant soup mix, Coffee creamer, Non-dairy creamer, Baby formula powder, Custard powder, Cake mix, Flavored drink mix, Protein supplements, Maltodextrin, Instant coffee granules, Cheese powder

- Steps before

- Purification, Emulsification, Grinding, Mixing, Atomization

- Steps after

- Agglomeration, Cooling, Filtering, Packing, Quality Control

- Input ingredients

- liquid feed, instant coffee, food ingredients, chemical compounds, water, melt, solution containing substances

- Output ingredients

- uniform coarse powder, agglomerated powder, free-flowing powder, dustless powder

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Drying Stages

- 3 stages

- Atomization Method

- Nozzles

- Drying Air Velocity

- High

- Airflow Direction

- Vertical

- Secondary Agglomeration

- Defined

- Additional Agglomeration

- FSD-GRANULATOR®

- Automation

- PLC-controlled

- Evaporation Time

- Instantaneous

- Fluid Bed Integration

- VIBRO-FLUIDIZER®

- Moisture Content Adaptation

- Variable

- Working mechanism

- Spray and fluid-bed drying

- Integrated steps

- Multi-stage drying process

- Batch vs. continuous operation

- Continuous operation

- Automation level

- Advanced automation for controlled drying phases

- Cleaning method

- CIP compatibility

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Non-agglomerated powder option

- Available

- Machine Footprint

- Compact Design

- Drying Chamber Shape

- Cylindrical with Integrated Fluid Bed

- Discharge Method

- VIBRO-FLUIDIZER® Fluid Bed

- Control Panel Type

- Advanced PLC for Process Control

- Control panel type

- Touchscreen / PLC

- Discharge method

- VIBRO-FLUIDIZER® Fluid Bed

- Compact footprint

- Customizable based on requirement

- Automation level

- Fully automated / Manual setup available

- Drying integration

- Spray drying and fluid-bed drying integration

- Agglomeration control

- Additional liquid agglomeration via FSD-GRANULATOR®