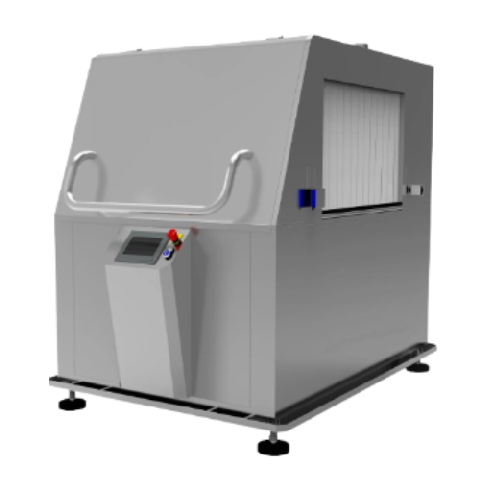

Hot water dip tank for immersion shrinking

Enhance the appearance and seal integrity of vacuum-packaged products with a robust and efficient immersion shrinking solution designed to withstand the harsh conditions of food processing environments.

Enhances Packaging by Immersion Shrinking

The Dip Tank TU 1080 from Starvac Systems is a robust immersion shrinking solution tailored for food production and packaging companies. This unit is engineered with a solid stainless steel structure, offering exceptional corrosion resistance in harsh environments such as meat, cheese, fish, and poultry packaging. It employs electric heating elements to maintain precise water temperatures, ensuring optimal shrinkage and sealing of vacuum-packed products. Operated by a sophisticated PLC system, the TU 1080 allows precise control over immersion times and can seamlessly switch to conveyor mode for products not requiring shrinkage. With an 800 mm inlet width and 250 mm immersion depth, it integrates effortlessly into both manual and automatic production lines, enhancing packaging aesthetics and integrity while optimizing throughput.

Benefits

- Enhances product presentation and seal integrity, improving shelf appeal and ensuring freshness.

- Offers versatile operation modes, accommodating both shrinking and non-shrinking packaging needs.

- Minimizes maintenance with stainless steel construction, reducing long-term operational costs.

- Increases operational efficiency with precise PLC control, optimizing processing time and water temperature.

- Integrates seamlessly into existing production lines, enhancing workflow without extensive modifications.

- Applications

- Poultry packaging, Food production, Vacuum packaging, Cheese packaging, Food processing, Meat packaging, Fish packaging, Packaging equipment, Food preservation

- End products

- Sealed sausage packs, Packaged smoked salmon, Vacuum-sealed cheese blocks, Packaged ready-to-eat meals, Vacuum-packed fish fillets, Vacuum-sealed poultry portions, Vacuum-sealed meat cuts, Preserved deli meats

- Steps before

- Vacuum packing, Sealing, Product assembly

- Steps after

- Cooling, Quality inspection, Final packing

- Input ingredients

- packaged products, products for shrink wrapping, vacuum packed items

- Output ingredients

- sealed packaged products, shrink-wrapped items, enhanced packaging appearance

- Market info

- Starvac Systems is known for manufacturing high-quality vacuum systems and engineered solutions tailored to various industrial applications. They are reputed for their innovation, reliability, and technical expertise in delivering custom-engineered vacuum equipment.

- Material

- Stainless steel

- Water heating

- Electric heating elements

- Automation

- PLC-controlled

- Immersion depth

- 250 mm

- Inlet width

- 800 mm

- Length

- 1000 mm

- Water immersion time

- Selectable

- Water temperature

- Selectable

- Working Mechanism

- Electric heating elements

- Automation Level

- PLC-controlled

- Batch vs. Continuous Operation

- Batch

- Control System

- PLC for operation and control

- Temperature Control

- Selectable water temperature

- Time Control

- Selectable water immersion time

- Multi-functionality

- Can exclude immersion, use as conveyor

- Corrosion Protection

- Protected against corrosive factors

- Material

- Stainless steel structure

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- Moderate

- Machine structure material

- Stainless steel

- Machine footprint

- 1000 mm x 800 mm

- Immersion depth

- 250 mm

- Inlet width

- 800 mm

- Control system

- PLC-controlled

- Control panel type

- PLC-controlled

- Integration possibilities

- Integration with Saccardo vacuum packing machines

- Selectable immersion time

- Yes

- Water temperature selection

- Yes

- Operation mode

- Manual/Automatic