Magnetic separators for metal contaminant removal in powder processing

Ensure product purity and safety by effectively removing metal contaminants from powder processing lines with cutting-edge magnetic separation technology.

Removes Metal Contaminants in Powder Processing

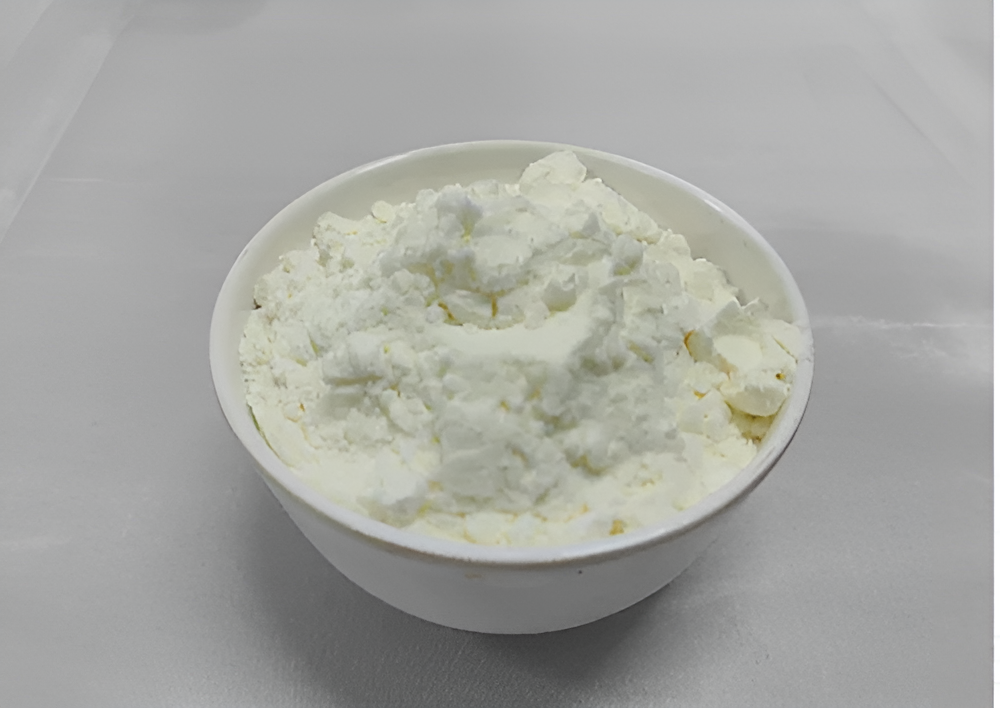

The MAG-RAM™ Self-Cleaning Grate Magnet from Powder Process-Solutions integrates seamlessly into your production process to efficiently remove metal contaminants from dairy, food, and pharmaceutical powders. Its self-cleaning mechanism ensures continuous operation with minimal downtime, utilizing a high-strength, 11,000+ gauss rare earth magnet to enhance product purity. Ideal for applications ranging from milk powder to nutraceutical formulations, this equipment meets rigorous hygiene standards with its sanitary, dust-tight design. Programmable control features facilitate easy integration into existing lines and allow for automated operations, reducing manual intervention. Constructed from durable stainless steel, it offers excellent corrosion resistance and meets industry compliance, making it an essential component for companies focusing on quality and safety assurance.

Benefits

- Ensures product safety and quality by effectively eliminating metal contaminants.

- Minimizes operational downtime with its self-cleaning feature.

- Supports seamless integration with existing production lines through automated controls.

- Reduces maintenance efforts due to its sanitary and dust-tight construction.

- Complies with industry hygiene standards, enhancing consumer confidence.

- Applications

- Nutritional powders, Infant nutrition, Specialty powders, Food products, Pharmaceutical powders, Dairy products

- End products

- Nutraceutical formulations, Infant formula, Snack foods, Medicines, Vitamin supplements, Milk powder, Yogurt powder, Protein supplements, Seasoning blends, Cheese powder

- Steps before

- Grinding, Milling, Ingredient Weigh Batching, Mechanical Conveying

- Steps after

- Packing, Filling, Mixing, Blending

- Input ingredients

- food powder, dairy powder, nutritional powder, metal fragments, ferrous materials, large metal contaminants

- Output ingredients

- metal-free food powder, metal-free dairy powder, metal-free nutritional powder, contaminant-free material

- Market info

- PPS (Powder Process-Solutions) is known for designing and manufacturing custom powder handling systems and equipment, specializing in sanitary process solutions for the food, dairy, and nutritional industries, ensuring safety, efficiency, and regulatory compliance.

- Magnetic Strength

- 11, 000+ gauss

- Cleaning Method

- Quick-clean / Self-cleaning

- Construction

- Dust-tight

- Material Type Detected

- Small ferrous / Large metal contaminants

- Working Mechanism

- Magnetic Separation

- Automation Level

- Self-Cleaning / Manual

- CIP/Sanitary Design

- Dust-tight, Sanitary

- Batch vs. Continuous Operation

- Inline/Bulk Solids Conveying

- Magnetic Strength

- 11, 000+ gauss

- Removal Efficiency

- Proven Magnetic Separation Proficiency

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Magnet type

- Grate / Inline / Custom

- Cleaning capability

- Self-cleaning / Quick-clean

- Construction type

- Dust-tight

- Design feature

- Sanitary

- Magnetic strength

- 11, 000+ gauss

- Footprint

- Compact

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- SCADA / DCS / MES

- Magnet configuration

- Grate / Inline / Custom

- Self-cleaning capability

- Automated / Manual

- Material Construction

- Stainless Steel / Sanitary Design