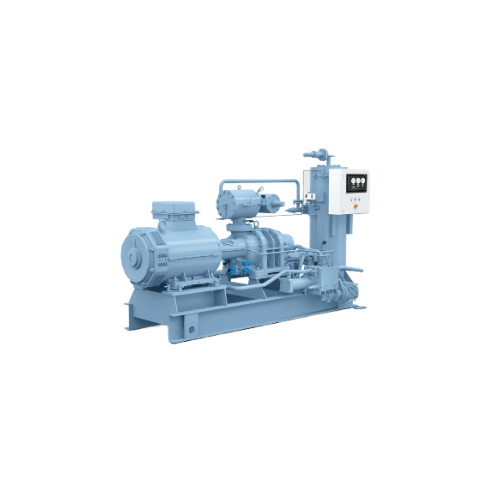

Single-stage screw compressor package

Optimize your refrigeration and heating processes with versatile packages designed to handle complex cooling and high-pressure applications, ensuring seamless integration into your production line.

Compresses and Regulates Temperature for Diverse Applications

The GEA Grasso SP1 series from GEA is a versatile single-stage screw compressor package designed to tackle a wide array of thermal management challenges in industries such as food, chemical, and pharmaceutical production. Featuring a customizable range from 638 kW to 9,423 kW in cooling capacity, the SP1 offers seamless integration into your production line with stepless capacity control via frequency inverter and slide system, ensuring precise thermal regulation.

Ideal for applications from cooling frozen vegetables to heating chemical solvents, this series is engineered to handle high-pressure CO2 and ammonia heat pump operations efficiently. The horizontal variant provides a reduced footprint by up to 20%, accommodating spatial constraints without compromising performance.

Equipped with a GEA Omni control panel fitted with a high-definition 15.6″ touchscreen, the SP1 supports remote monitoring and is adaptable to both continuous and high-speed automated processes. Optional variable speed drive motors add further efficiency by adjusting to operational demands, significantly reducing energy consumption.

Built to withstand harsh conditions, the SP1 package offers corrosion-resistant materials and adheres to industry-specific certifications, providing long-term reliability and compliance. Engineered for ease of maintenance, it includes features like CIP systems for efficient cleaning and offers extensive customization options, supported by GEA’s engineering expertise to meet your specific production requirements.

Benefits

- Optimizes energy efficiency, reducing consumption with variable-speed drive motors.

- Adapts to specific production needs with customizable configurations.

- Minimizes spatial impact with compact horizontal design.

- Enhances operational control with user-friendly touchscreen interface.

- Ensures compliance and durability for demanding industrial applications.

- Applications

- Food, Marine, Gas and energy, Beverage, Refrigeration, Oil, Heating, Chemical, Pharma, Healthcare, Dairy

- End products

- Heating elements, Natural gas liquids, Refrigerated goods, Frozen vegetables, Cheese, Biopharmaceuticals, Ship refrigeration systems, Chemical solvents, Chilled beverages, Milk powders, Yogurt, Pharmaceutical vaccines

- Steps before

- Purification, Cooling process initiation, Industrial setup configuration

- Steps after

- Heat recovery, Packaging, Heat exchange, Further processing

- Input ingredients

- R717, Ammonia, subcritical CO2, R290

- Output ingredients

- cooling capacity, -10/+35 °C, -40/-10 °C

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Speed

- 1, 500 - 3, 600 rpm

- Cooling Capacity

- 638 kW to 9, 423 kW

- Refrigeration Capacity

- 638 kW to 9, 423 kW (R717 | -10/+35°C | 3, 600 rpm)

- Capacity Control

- Stepless via frequency inverter and/or slide system

- Speed Range

- 1, 500 - 4, 500 rpm (R to T models)

- Heat Pump Applications

- Ammonia and subcritical CO2

- Models

- 16 models, horizontal variant 9 models

- Horizontal Design Footprint

- Up to 20% less than vertical version

- Control Panel

- GEA Omni control panel with 15.6" touchscreen

- Screw Compressor Sizes

- Frame size E to XA

- Operating Temperature Range

- -10/+35°C

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Stepless capacity control

- Frequency inverter / Slide system

- Reduced footprint

- Up to 20% less

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes, Ammonia compatible

- Density/particle size

- Not applicable for this type of equipment

- Application versatility

- Food industry, CO2 high-pressure, heat pump, explosion-proof for chemical applications

- Compact footprint

- Horizontal variant offers up to 20% less footprint

- Control panel type

- GEA Omni control panel with high-definition 15.6" touch screen

- Discharge method

- Customizable

- Control panel type

- GEA Omni control panel with 15.6" touch screen

- Compact footprint

- Up to 20% reduced footprint