Tray packing for square and rectangular cheese portions

Optimize your cheese packaging line with high-speed tray forming and sleeving, ensuring smooth operation and precise portion control for diverse cheese products.

Forms, Sleeves, and Fills Cheese Trays

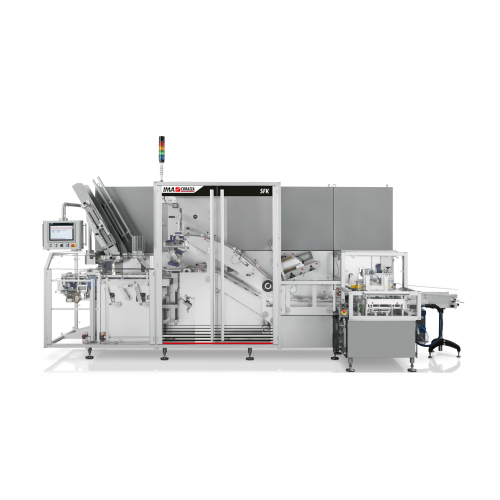

The SFK Series from IMA Group is a versatile tray forming and sleeving machine uniquely designed for the food and dairy industries. It offers compact dimensions and the flexibility to handle a range of cheese products, from cheddar portions to mozzarella cubes, at speeds up to 120 units per minute. The machine’s modular configuration allows for one to three lanes and layers, tailored to your production needs. With an emphasis on sustainability, it integrates kinetic energy recovery during braking, significantly reducing power waste. It also features vacuum pumps to minimize compressed air consumption, allowing for the use of recyclable packaging materials. The SFK Series ensures seamless integration into high-speed, continuous operations while maintaining optimal energy efficiency. Constructed to handle 75 boxes per minute at full load, it requires 150 Nl/min of compressed air and operates at a vacuum of 600 ± 50 mm Hg. You can expect straightforward maintenance and quick changeovers, making it ideal for cheese manufacturers and food packaging companies seeking effective and sustainable solutions.

Benefits

- Increases packaging efficiency with up to 120 units per minute.

- Minimizes energy costs with kinetic energy recovery and reduced air consumption.

- Supports environmental sustainability through the use of recyclable packaging materials.

- Customizable configurations cater to diverse production requirements.

- Simplifies maintenance and reduces changeover time, enhancing operational uptime.

- Applications

- Tray packed foods, Dairy products, Cheese, Packaged foods

- End products

- Cottage cheese packs, Mozzarella cubes, Ricotta in trays, Processed cheese slices, Havarti cheese blocks, Gouda cheese slices, Cream cheese trays, Swiss cheese squares, Brie cheese wedges, Cheddar cheese portions

- Steps before

- Cutting, Portion Grouping

- Steps after

- Tray Outfeed, Sleeve Formation, Packing

- Input ingredients

- square cheese portions, rectangular cheese portions

- Output ingredients

- tray packed cheese, sleeved cheese trays

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production Capacity

- Up to 75 boxes/min

- Full Load Current

- 3P x 400 Volt – 50 Hz – 7 Amp

- Compressed Air Consumption

- 150 Nl/min (op. pressure 6 bar)

- Vacuum

- 2 m³/h (op. vacuum 600 ± 50 mm Hg)

- Machine Weight

- 3, 200 Kg Approx

- Box Dimensions - A

- 80 ÷ 124

- Box Dimensions - B

- 80 ÷ 250

- Box Dimensions - C

- 12 ÷ 45

- Lanes

- 1 ÷ 3

- Layers

- 1 ÷ 3

- Speed

- Up to 120 ppm

- Compact Footprint

- Yes

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick changeover

- Energy efficiency

- Kinetic energy recovery

- Cleaning method

- Manual

- Compressed air reduction

- Vacuum pump option

- Compact footprint

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Square / Rectangular portions

- Speed

- Up to 120 ppm

- Product type

- Cheese

- Tray type

- Formed / Sleeved

- Lane options

- 1 to 3 lanes

- Layer options

- 1 to 3 layers

- Box dimensions (A)

- 80–124 mm

- Box dimensions (B)

- 80–250 mm

- Box dimensions (C)

- 12–45 mm

- Compressed air usage

- 150 Nl/min at 6 bar

- Vacuum requirements

- 2 m³/h at 600 ± 50 mm Hg

- Power

- 3P x 400 Volt – 50 Hz – 7 Amp

- Machine footprint

- Compact

- Box dimensions (A)

- 80 ÷ 124 mm

- Box dimensions (B)

- 80 ÷ 250 mm

- Box dimensions (C)

- 12 ÷ 45 mm

- Tray handling capability

- Square and rectangular portions

- Lanes

- 1 ÷ 3

- Layers

- 1 ÷ 3

- Machine Weight

- 3, 200 Kg Approx.

- Control panel type

- HMI available

- Compact footprint

- Yes

- Configuration options

- Multiple according to customer's needs

- Changeover time

- Quick changeover

- Sustainability features

- Recyclable packaging materials, energy-efficient motorization