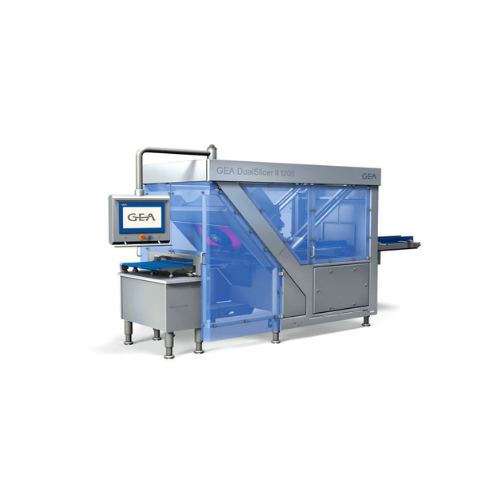

Industrial slicer for natural shaped food products

Achieve superior slicing precision and efficiency with high-speed technology, ideal for producing consistently portioned cheese and meat slices. Perfect for improving yield and reducing waste in high-volume production lines.

Slices and Loads Meat and Dairy Products

The GEA DualSlicer II 1200 is a high-speed industrial slicer that revolutionizes precision slicing for food manufacturers. Designed to target the specific needs of cheese producers, meat processors, and ham processing companies, this slicer employs twin, independent drives with top and bottom traction systems to process two logs simultaneously. Ideal for slicing natural-shaped products like cheddar, gouda, prosciutto, and smoked bacon strips, this equipment ensures consistent slice thickness and minimal waste.

Using advanced involute blade technology, the GEA DualSlicer II achieves high-quality portions with reduced give-away, making it perfect for handling delicate products such as soft boiled sausage and creating intricate portions like folded or interleaved slices. Its automatic loading feature, combined with optional add-ons like the GEA Check 4000 weighing system and GEA OptiScanner for density analysis, enables seamless integration into your production line with continuous monitoring and optimization.

This slicer boasts impressive throughput, able to manage products up to 1,200 mm in length with slice widths reaching 500 mm. The energy-efficient design operates at a maximum power supply of 11 kW, offering substantial savings while maintaining performance. Designed for easy operation and maintenance, the slicer includes a clearly illustrated operator display and tool-free access to all side panels for swift cleaning, ensuring minimal downtime and compliance with hygiene standards.

GEA provides customization options and engineering support to tailor the DualSlicer II to your specific processing needs, making it a versatile addition to any meat processing, dairy, or cheese production facility.

Benefits

- Enhances slicing precision and reduces product waste, improving overall yield.

- Increases production efficiency with dual-log processing and high-speed operation.

- Offers versatile slicing applications, accommodating various meat and cheese types.

- Minimizes cleaning and maintenance time with easy-access design and tool-free panel removal.

- Reduces energy consumption with optimized power usage and efficient design.

- Applications

- Cheese, Cooked ham, Sausages, Salami, Bacon, Raw ham

- End products

- Smoked bacon strips, Serrano ham, Vienna sausages, Cooked ham slices, Bratwurst, Prosciutto, Cheddar slices, Salami slices, Pancetta, Gouda slices

- Steps before

- Product Loading, Pre-Scanning, Density Determination

- Steps after

- Weighing, Interleaving, Folding, Packaging

- Input ingredients

- cheese, raw ham, cooked ham, calibrated sausage, salami

- Output ingredients

- slices, shingle, stack, zig zag stack, shaved, pieces, folded, interleaved

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Type of blade

- Involute blade

- Blade size

- R 470 mm

- Max. blade speed

- 1, 500 rpm

- Cutting cross-section

- Width 500 mm up to max. product height 145 mm

- Max. product length

- 1, 200 mm

- Machine dimensions

- L x H x W 3, 890 x 2, 480 x 1, 350 mm

- Product loading

- Automatic

- Power supply

- 11 kW

- Compressed air

- 6 bar 15 – 600 L/min

- Noise emission

- < 76 db (A)

- Avoidance of sliver slices

- Idle Cut Technology

- Automation level

- PLC controlled

- Changeover time

- Fast changeover

- CIP/SIP

- Easy cleaning access

- Cleaning method

- Manual / Easy access

- Energy efficiency

- High performance, low energy

- Portion forms

- Shingle / stack / zig zag / folded

- Slicing reliability

- Consistent slice thickness

- Product shape compatibility

- Natural-shaped, Regular-shaped

- Product type

- Cheese, Cooked Ham, Raw Ham, Sausage, Salami

- Slice thickness variability

- Variable thickness for each product

- Machine dimensions L x H x W

- 3, 890 x 2, 480 x 1, 350 mm

- Max. product length

- 1, 200 mm

- Cutting cross-section

- Width 500 mm up to max. product height 145 mm

- Discharge method

- Automatic

- Compact footprint

- Low footprint and perfect hygienic design

- Control panel type

- Clearly structured and illustrated operator display

- Blade size

- R 470 mm

- Max. blade speed

- 1, 500 rpm

- Weight measurement system

- GEA Check 4000, 1- up to 4-lane configuration

- Control panel type

- Clearly structured and illustrated operator display

- Integration possibilities

- Telemonitoring/Remote services, GEA Performance Service

- Custom slicing configuration

- Idle Cut Technology, Involute Blade Technology

- Product handling options

- GEA Check 4000, GEA OptiScanner, GEA Interleaver, GEA Folding Device