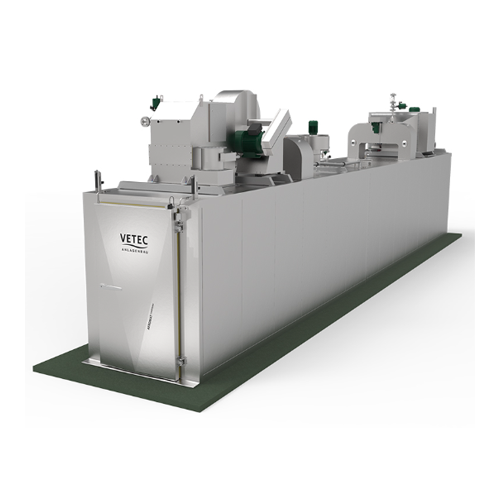

Advanced processing unit for meat and fish products

Transition seamlessly from hot to cold processing with a system that enhances product quality, minimizes weight loss, and reduces bacterial risks, ensuring your production line operates efficiently and effectively.

Combines Smoking, Cooking, and Cooling Processes

The Aeromat Compound from VETEC Anlagenbau is a versatile system that efficiently integrates smoking, cooking, and intensive cooling. Ideal for processing boiled and raw sausages, cured meats, smoked fish, and cheese, it reduces energy consumption by up to 30% with optional heat recovery and precise temperature control. Its semi-continuous operation ensures minimal manual intervention, enhancing hygiene and reducing bacterial risks by swiftly navigating the critical temperature range. With automated PLC control, it facilitates seamless integration into food processing lines, offering customizable options like various heating methods and complete CIP systems for easy maintenance. Constructed from durable materials, it’s engineered for reliability and compliance with stringent food safety standards.

Benefits

- Achieves consistent product quality with automated, precise temperature transitions.

- Reduces energy costs by up to 30% through efficient heat recovery systems.

- Minimizes bacterial contamination with rapid process flows and minimal handling.

- Lowers labor costs due to semi-continuous, automated operation.

- Ensures hygiene compliance with an integrated CIP system and automated cleaning features.

- Applications

- Cooked sausage, Pet food, Cheese, Thawed products, Boiled sausage, Raw sausage, Cured meat products, Fish

- End products

- Kibble, Bologna sausage, Chorizo, Frankfurters, Defrosted shrimp, Cheddar cheese, Smoked salmon, Pastrami

- Steps before

- Reddening, Drying, Smoking, Cooking

- Steps after

- Packaging

- Input ingredients

- boiled sausage, raw sausage, cooked sausage, cured meat products, fish, thawed products, pet food, cheese

- Output ingredients

- smoked products, cooked products, cooled products, packaging-ready products

- Market info

- Vetec is known for its expertise in manufacturing customized industrial valves and actuators, catering to diverse industries with a reputation for reliability, precision engineering, and innovative solutions tailored to specific customer requirements.

- Heating Method

- Steam heated, direct gas heated, electrically heated

- Cooling System

- Cold water circulation system

- Automation

- Automatic product transportation

- Cycle through temperature range

- Rapid pass through 40°C - 15°C

- Energy Consumption Reduction

- Up to 30% with heat recovery ECOCON

- Conveyor System

- Bidirectional movement

- CIP System

- Fully automatic with rotating nozzles

- Integrated processes

- Smoking, Cooking, Cooling

- Handling system

- Semi-continuous

- Automation level

- Automatic transportation and door operation

- Batch vs. continuous operation

- Semi-continuous

- Cleaning method

- Fully automatic CIP-System

- Energy efficiency

- Heat recovery options available

- Cleanability

- Fully automatic CIP-System

- Corrosive resistance (e.g. acids)

- Stainless steel construction for hygiene and resistance

- Cooling requirements

- Elimination of cost-intensive cooling surfaces

- Product type

- Boiled, raw, cooked sausage, cured meat, fish, cheese, pet food

- Smoking process

- Hot-smoking and cold-smoking facilities

- Disinfection requirement

- Facility allows cooking with steam

- Machine footprint

- Semi-continuous handling system footprint

- Discharge method

- Automatic transportation from section to section

- Control panel type

- Electric handling device

- Compact footprint

- Designed for semi-continuous operation

- Door variants

- Roller door / Rising and falling door

- Control panel type

- PLC-controlled

- Door type

- Roller / Automatic rising and falling

- Heating type

- Steam / Gas / Electric

- Smoke generator type

- Glowing / Liquid / Steam / Friction

- Handling system

- Electric handling device

- CIP system

- Fully-automatic

- Cooling system

- Cold water circulation