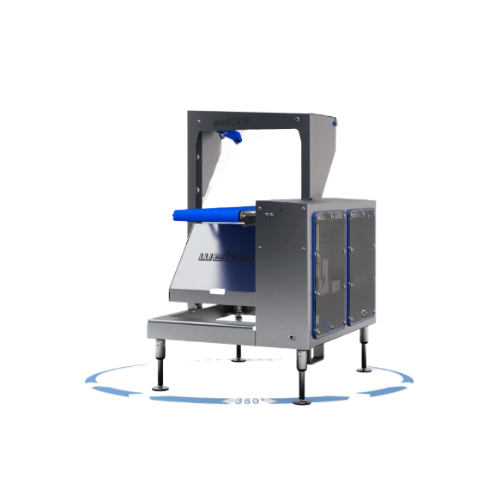

Involute blade slicer for diverse product range

Maximize throughput and efficiency with this advanced slicing solution, ideal for food processors handling a diverse range of products—from meats to vegan offerings. Optimize your production with precision cutting, reduced setup times, and enhanced product handling.

Slices and Portions Diverse Food Products

The Weber weSLICE 4000 and 4500 slicers offer flexible slicing solutions for food processing, featuring both circular and involute blade systems for precise cuts across a wide range of products, including cheese, meats, and plant-based alternatives. Engineered for medium output operations, these slicers are ideal for manufacturers handling diverse product lines, such as prosciutto, turkey breast, tofu, and grilled vegetables. The units integrate into production lines seamlessly, allowing manual or automatic loading for streamlined operations. With a slicing speed reaching up to 1500 rpm and adjustable slicing thickness from 0.5 to 50 mm, the weSLICE series accommodates varied production needs. The compact design allows for significant space savings while ensuring reduced setup times, thus enhancing production efficiency. The slicers prioritize hygiene and ease of maintenance with their Weber Hygiene Design, optional SprayTech cleaning technology, and readily accessible components. Customization is supported, with optional interleaving features and automatic cutting gap adjustment available, ensuring precise portion control.

Benefits

- Enhances operational efficiency with compact design that reduces setup times and labor costs.

- Increases product variety adaptability, supporting both small-batch and large-scale slicing needs.

- Optimizes production flow with automatic and manual loading options.

- Maintains high hygiene standards with Weber Hygiene Design, minimizing contamination risk.

- Offers precision and flexibility with adjustable slicing thickness and optional interleaving features.

- Applications

- Deli, Snacks, Sandwich, Ready meal, Vegetarian, Cheese, Convenience, Cooked ham, Veggie, Vegan, Raw sausage, Bacon, Raw ham, Fresh meat, Fish, Petfood

- End products

- Meal kits, Sliced cheddar cheese, Club sandwiches, Gourmet pet food slices, Turkey breast deli slices, Honey glazed ham, Pepperoni slices, Tofu slices, Grilled vegetable slices, Seitan pieces, Microwave-ready pasta dishes, Protein snack packs, Crispy bacon strips, Fresh salmon fillets, Prosciutto di parma

- Steps before

- Preparation, Product loading, Central loading, Manual loading, Material setup

- Steps after

- Packing, Packaging, Portioning, Labeling, Sorting

- Input ingredients

- cheese, raw ham, bacon, deli, cooked ham, raw sausage, snacks, convenience items, veggie, vegan, fresh meat, fish, pet food, ready meal, sandwich, whole muscle

- Output ingredients

- stacked slices, staggered stack, shingled-stack, cross-shingled, multi-shingled, endless-shingled, shaved pieces, folded portions, circular portions, oval portions, overlapped slices, multiple overlaps

- Market info

- Weber Maschinenbau Germany is renowned for its innovative solutions in the food processing industry, specializing in industrial slicing machines and equipment for high-quality meat and cheese processing, offering precision and efficiency to leading global manufacturers.

- Slicing speed

- max. 1500 rpm

- Product throat height

- 120/135/150 mm

- Product throat width

- 330 mm

- Product length

- max. 1200 mm

- Slicing system

- Circular blade / Involute blade

- Slicing thickness

- 0.5-50 mm

- Loading

- automatically/manually

- Working mechanism

- Circular blade / Involute blade

- Loading method

- Manual / Automatic central loading

- Batch vs. continuous operation

- Batch

- Customization level

- Optional with idle cut blade head and automatic cutting gap adjustment

- Cutting precision

- 0.5-50 mm slicing thickness

- Automation level

- Manual / Automatic

- Product handling flexibility

- Supports large product variety

- Set-up time

- Quick set-up time

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Variety

- Wide Range

- Machine footprint

- Compact

- Feed/Discharge method

- Manual and automatic central loading

- Loading method

- Manual/Automatic

- Loading Type

- Manual / Automatic central

- Blade Type

- Circular / Involute

- Portion Designer

- Circular / Oval

- Blade Head

- Idle cut blade

- Cutting Gap Adjustment

- Automatic