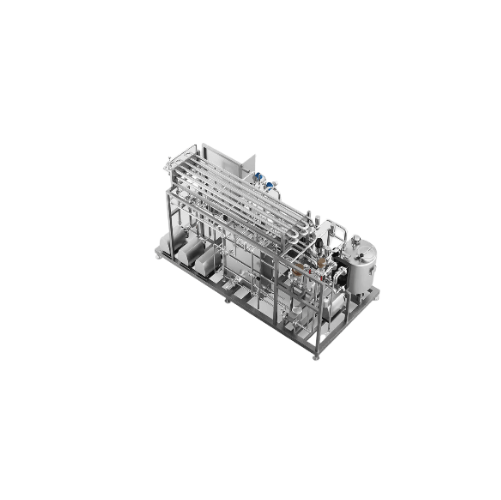

Small-scale milk pasteurizer with skimming centrifuge

Quickly integrate a versatile pasteurization system into your production line, reducing downtime with its compact, pre-assembled design that efficiently processes milk and cream, ensures optimal product quality, and supports flexible operations.

Processes and Skims Milk for Dairy Production

The GEA milk Pasteurizer, available in models 3000, 5000, and 10000, is a versatile, skid-mounted unit designed for dairy processors and milk processing companies seeking efficient pasteurization and skimming capabilities. This system integrates a skimming centrifuge, enabling continuous processing of milk and cream, and offers optional features such as partial homogenization and yogurt treatment to broaden its application scope. With throughput capacities ranging from 3,000 to 10,000 liters per hour, it is adept for producing pasteurized milk, cream, cheese, and yogurt. The unit is PLC-controlled and features a user-friendly HMI for easy operation and integration into existing production lines. Its compact design ensures minimal space requirements, while pre-assembly promotes quick on-site installation and commissioning. Additionally, the construction supports CIP for effective cleaning and maintenance, contributing to reduced downtime. The GEA milk Pasteurizer delivers customizable options to enhance its utility, such as post-heating for cheese production and remote access capabilities for improved operation monitoring.

Benefits

- Streamlines production with integrated pasteurization and skimming processes for diverse dairy applications.

- Minimizes installation time and costs with a pre-assembled, skid-mounted design.

- Enhances product quality through customizable options like partial homogenization and post-heating.

- Reduces operational downtime with efficient CIP systems and easy maintenance.

- Facilitates remote monitoring and control, improving operational efficiency and response times.

- Applications

- Cream, Food, Milk, Beverage, Cheese milk, Yoghurt milk, Liquid processing, Dairy

- End products

- Cheese, Yoghurt, Pasteurized cream, Pasteurized milk, Fermented dairy products, Drinking milk

- Steps before

- Milk collection, Raw milk storage, Milk cooling

- Steps after

- Skimming, Cream cooling, Cheese vat feeding, Yoghurt fermentation, Packaging

- Input ingredients

- raw milk, cream

- Output ingredients

- pasteurized milk, skimmed milk, cream

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 3, 000 to 10, 000 l/h

- Skimming centrifuges

- GEA milk Skimmer pro 20, GEA milk Skimmer pro 40, GEA ecocream

- Automation

- User-friendly HMI, IOT ready

- Heating Temperature

- Up to 90 °C for yogurt milk treatment

- Post Heating

- 20–45 °C for cheese milk and yogurt milk

- Holding Time

- 6 min for yogurt milk treatment

- Pressure-priming Pump

- Yes, with differential pressure control

- Cream Cooler

- 8 °C cooling for intermediate storage

- Partial Homogenization

- Available for drinking and yogurt milk

- Quick Commissioning

- Yes, skid mounted

- Working mechanism

- Continuous inline

- Integrated steps

- Pasteurization and skimming

- CIP Principles

- Optimized CIP process for time efficiency

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- User-friendly HMI

- PLC and remote access

- Relocation capability

- Easy relocation

- Skid mounted

- Complete system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type

- Milk / Cream

- Skimming capability

- Yes

- Homogenization

- Partial

- Pasteurization type

- Batch / Continuous

- Compact footprint

- Yes

- Skid mounted solution

- Yes

- Capacity

- 3, 000 to 10, 000 l/h

- Flexibility in operation

- Milk and cream processing

- Discharge method

- N/A

- Control panel type

- User-friendly HMI

- Pressure-priming pump + differential pressure control

- Provides additional process safety

- Cream cooler

- Cools the cream down to 8 °C

- Post heating for cheese milk

- 20 - 45 °C post heating

- Yogurt milk treatment

- 90 °C increased heating temperature, 6 min holding time

- Partial homogenization

- Prevent cream separation, better yogurt structure

- Lost CIP

- CIP dosing system for caustic and acid concentrates

- Anybus gateway

- Signal exchange

- MGuard

- Remote access

- Automation via HMI

- User-friendly operation, automatic and manual mode

- IOT ready

- Remote access option