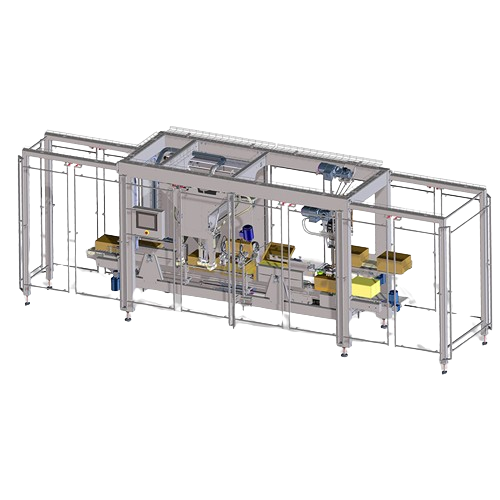

De-boxing system for cheddar blocks

Streamline your cheddar cheese production with efficient de-boxing, ensuring seamless integration into high-speed processing lines for optimal throughput.

De-Boxes and Transports Cheddar Blocks

The De-Boxing DBM from ALPMA Alpenland Maschinenbau GmbH is an efficient solution for dairy producers and cheese manufacturers, offering a fully automatic system for de-boxing cheddar blocks. This equipment stands out with its high-speed capability, processing up to 20 boxes per minute, ensuring uninterrupted flow in high-demand production environments. The machine’s core function involves seamlessly transferring de-boxed cheddar blocks to subsequent de-bagging machines, like the FAP, facilitating streamlined operation in cheese processing and packaging lines.

Designed for integration in food and dairy processing facilities, the DBM caters to a range of applications, including processing cheddar cheese portions, cheese cubes, and packaged cheddar snacks. The system is equipped with advanced automation technology that enhances precision and minimizes manual handling, ensuring product consistency and quality.

The DBM is engineered with robust materials suitable for the rigorous demands of the food processing industry, supporting hygiene and longevity. Its modular design allows for easy maintenance and compatibility with existing processing infrastructure. Whether you are focusing on pre-processing or packaging, this machine enhances operational efficiency, supports consistent throughput, and reduces labor requirements in cheese production lines.

Benefits

- Increases production efficiency by processing up to 20 boxes per minute.

- Enhances operational safety and reduces manual handling with fully automated de-boxing.

- Optimizes integration within existing processing lines, ensuring smooth transition to subsequent packaging steps.

- Supports high product quality and consistency with precise handling of cheddar blocks.

- Minimizes maintenance downtime with durable construction and easy-to-service design.

- Applications

- Snacks, Food processing, Cheese blocks, Cheddar cheese, Dairy products

- End products

- Cheese snacks, Cheese cubes, Packaged cheddar cheese, Cheddar blocks, Cheddar cheese portions

- Steps before

- Boxing, Film-ripening, Cheddar block production

- Steps after

- De-bagging, Transportation to carton baler, Packaging

- Input ingredients

- cheddar blocks, boxes, film-ripened cheddar

- Output ingredients

- de-boxed cheddar, carton baler-ready cheddar

- Market info

- ALPMA Alpenland Maschinenbau is known for specializing in manufacturing cutting-edge machinery and processing equipment for the cheese and dairy industry, holding a strong reputation for innovation, quality, and highly engineered-to-order solutions globally.

- Capacity

- max. 20 boxes/min

- Format range - Length

- 360 mm

- Format range - Width

- 280 mm

- Format range - Height

- 180 mm

- Automation

- Fully automatic transportation

- Capacity

- Max. 20 boxes/min

- Format range

- Length

- Automation level

- Fully automatic transportation to the carton baler

- Batch vs. continuous operation

- Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product de-boxing type

- Cheddar blocks

- Machine Footprint

- Not specified

- Box Size (Length)

- 360 mm

- Box Size (Width)

- 280 mm

- Box Size (Height)

- 180 mm

- Feed/Discharge Method

- Fully automatic transportation

- Capacity

- Max. 20 boxes/min

- Transportation to carton baler

- Fully automatic