High-performance slicer for food processing

Achieve precise and consistent slices for your diverse range of food products with this high-speed slicer, designed to streamline your processing line, minimize waste, and enhance product quality, catering to evolving consumer preferences in convenience and gourmet offerings.

Precision Slices and Loads Diverse Food Products

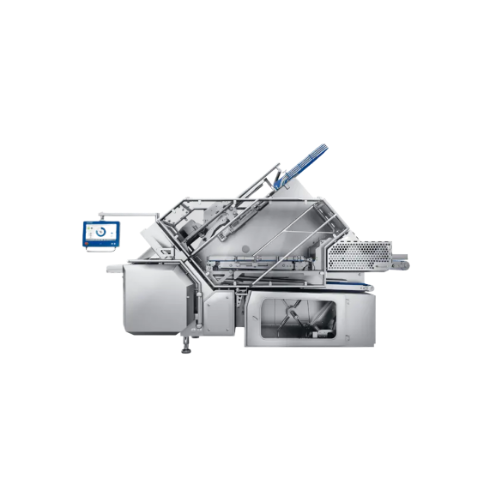

The weSLICE 9500 from Weber Food Technology is an industrial slicer designed for high-precision food processing across a variety of applications, including cheese, raw ham, bacon, and vegan products. This machine’s unique feature is the Weber DirectDrive technology, ensuring unparalleled slicing quality and capacity. It operates with a multi-stage process, allowing continuous slicing and loading, ideal for high-speed production environments. Capable of processing up to 1,850 rpm, it accommodates diverse end-products such as cheddar slices, smoked salmon, and plant-based burger patties. The slicer’s PLC-controlled system facilitates seamless integration into existing production lines, offering remote monitoring for operational efficiency. Crafted from durable materials, the weSLICE 9500 is built to withstand the demands of intensive food processing, while its hygienic design supports easy cleaning and maintenance. Additionally, Weber provides customization options, ensuring the slicer meets your specific operation needs.

Benefits

- Enhances operational efficiency through seamless integration with existing production lines.

- Supports diverse product handling, from fresh meat to vegan options, for versatile production capabilities.

- Minimizes labor with PLC-controlled, high-speed continuous operation.

- Ensures consistent product quality with precision slicing technology.

- Reduces downtime with easy-clean design and accessible maintenance features.

- Applications

- Deli, Snacks, Sandwich, Ready meal, Cheese, Convenience, Whole muscle, Cooked ham, Veggie, Vegan, Vegetarian/vegan, Raw sausage, Bacon, Raw ham, Fresh meat, Fish, Petfood

- End products

- Chicken sandwiches, Potato crisps, Smoked salmon slices, Lasagna ready meals, Salami slices, Plant-based burger patties, Tofu slices, Crispy bacon, Fresh beef fillets, Parma ham, Turkey deli slices, Vegan sausages, Dog treats, Cheddar slices, Pork loin filet, Cooked honey glazed ham, Pre-packed sandwiches

- Steps before

- Cutting preparation, Product loading, Yield management, Blade setup

- Steps after

- Weighing, Interleaving, Packaging, Sorting, Labeling

- Input ingredients

- cheese, raw ham, bacon, deli, cooked ham, raw sausage, snacks, convenience foods, veggie, vegan

- Output ingredients

- precise slices, caliber-consistent slices, food slices

- Market info

- Weber Maschinenbau Germany is renowned for its innovative solutions in the food processing industry, specializing in industrial slicing machines and equipment for high-quality meat and cheese processing, offering precision and efficiency to leading global manufacturers.

- Speed

- Up to 2, 000 rpm

- Capacity

- Varies per slicer model

- Automation

- DirectDrive Technology

- Product Throat Adjustment

- Auto-adjustable

- Loading Type

- Automatic or Manual

- Revolutions per Minute (RPM)

- 750–2, 000 RPM

- Slicing Edge

- Involute Blade System

- Product Length

- Up to 1, 700 mm

- Performance

- High performance for small-batch applications

- Changeover Time

- Minimized through automation

- Flexibility

- Handles a wide variety of products

- Entry-Level Model

- Manual loading

- Slicing speed

- Up to 2, 000 rpm

- Loading time

- Automatic/Manual

- Slicing method

- Involute blade system

- Automation level

- Manual / Automatic

- Product changeover time

- Minimized through automatic systems

- Product compatibility

- Soft mild cheese to hard raw ham

- Capacity

- High-performance capacity

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Blade type

- Involute blade

- Feed method

- Automatic loading

- Product throat adjustment

- Auto-adjustable

- Product length capability

- Up to 1, 700 mm

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- PLC / SCADA / ERP

- Footprint customization

- Compact / Modular

- Loading method

- Manual / Automatic

- Blade options

- Involute / Straight