Cartoning solutions for processed cheese products

Optimize your cheese production line with a cartoning solution that ensures precise packaging and efficient handling, perfect for reducing labor costs and minimizing packaging materials.

Wraps and Cartons Processed Cheese

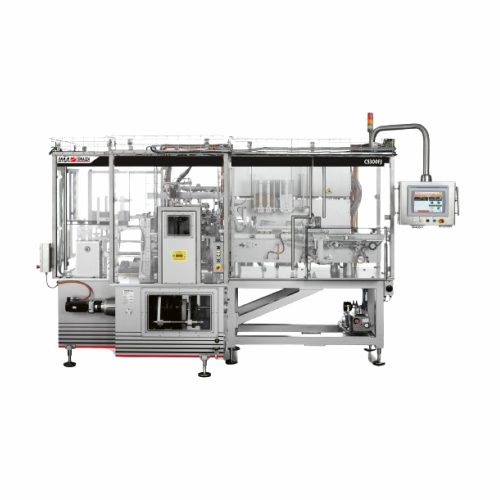

The CS300F from IMA Group is an automatic cartoning machine engineered for dairy and food processing environments, particularly excelled in handling various forms of processed cheese. Its modular design supports different infeed arrangements, facilitating the seamless packaging of cheese squares, rectangles, and wedges. The CS300F operates by utilizing open flat blanks, which are folded and sealed using cold vinyl glue, reducing procurement costs associated with pre-glued cartons. Capable of processing up to 75 boxes per minute, it ensures high-speed, continuous operation essential for keeping up with large-scale production demands. Equipped with optimized size tooling and an integrated lubrication system, the machine minimizes production downtimes and enhances operational efficiency. Its adaptability to handle single or multiple layers, along with options for a new wrap-around, flip-top reclosable box style, offers customization for specific packaging needs.

Benefits

- Enhances packaging efficiency by accommodating various infeed configurations.

- Decreases operational costs with reduced reliance on pre-glued cartons.

- Supports high-speed production, processing up to 75 boxes per minute.

- Minimizes downtime with quick changeover and integrated lubrication system.

- Customizable packaging solutions with options for new box styles and multiple layers.

- Applications

- Food, Dairy, Processed cheese

- End products

- Dairy product cartons, Cheese slices, Cheese bricks, Processed cheese rectangles, Cheese wedges, Cheese spread portions, Processed cheese squares

- Steps before

- Dosing, Wrapping, Pressing, Pouch filling, Form Fill and Seal, Horizontal form fill and seal

- Steps after

- Case packing, Palletizing

- Input ingredients

- square portions of processed cheese, rectangular portions of processed cheese, flat blanks

- Output ingredients

- pre-formed bundles, wrapped bundles, closed boxes, flip top reclosable box

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production capacity

- Up to 75 boxes/min

- Production capacity

- Up to 65 boxes/min (CS300FJ)

- Full load current

- 3P x 400 Volt – 50 Hz – 5 Amp

- Full load current

- 3P x 400 Volt – 50 Hz – 7 Amp (CS300FJ)

- Compressed air consumption

- 100 Nl/min (min. op. pressure 6 bar)

- Compressed air consumption

- 80 Nl/min (min. op. pressure 6 bar) (CS300FJ)

- Weight

- 1, 350 Kg Approx.

- Box dimensions A (min ÷ max)

- 35 ÷ 80

- Box dimensions B (min ÷ max)

- 75 ÷ 160

- Box dimensions C (max)

- 30 max

- Box dimensions A (min ÷ max) (CS300FJ)

- 61 ÷ 142

- Box dimensions B (min ÷ max) (CS300FJ)

- 114 ÷ 152

- Box dimensions C (max) (CS300FJ)

- 50 max

- Lanes

- 1 ÷ 2

- Layers

- 1 ÷ 2

- Carton style

- Wrap around

- Changeover time

- Optimised for minimal downtime

- Batch vs. continuous operation

- Continuous

- Automation level

- Automatic

- Cleaning method

- Partly pipeline fed lubrication system

- Energy efficiency

- N/A

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type

- Processed cheese

- Machine footprint

- Not specified

- Box dimensions (A)

- 35 ÷ 80 mm

- Box dimensions (A)

- 61 ÷ 142 mm

- Box dimensions (B)

- 75 ÷ 160 mm

- Box dimensions (B)

- 114 ÷ 152 mm

- Box dimensions (C)

- up to 30 mm

- Box dimensions (C)

- up to 50 mm

- Feed/discharge method

- Two parallel, horizontal belts

- Infeed arrangements

- Variety available

- Lubrication system

- Partly pipeline fed, partly sunk in oil

- Infeed Arrangements

- Available in different configurations

- Size Tooling Change

- Optimized for minimal downtime

- Box Style

- Wrap around flip top reclosable

- Portion Handling

- Small, medium and large cheese or product portions