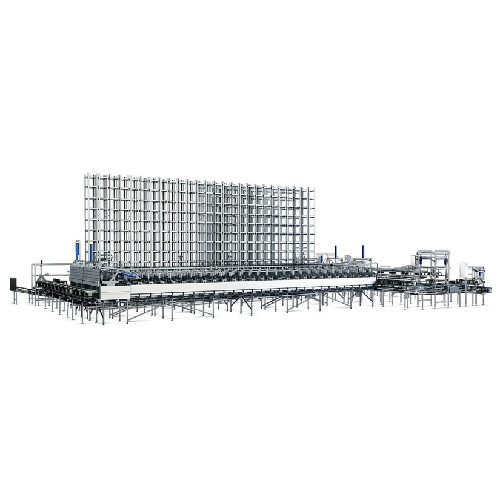

Cheese mould handling system for semi-hard and hard cheeses

Streamline your cheese production with an advanced system designed for seamless mould handling, pressing, and de-moulding of semi-hard and hard cheeses, ensuring consistent quality and hygiene with every batch.

Presses and Handles Semi-Hard and Hard Cheese

The Tetra Pak® Mould Handling System offers a sophisticated solution for dairy producers and cheese manufacturers. Designed for processing semi-hard and hard cheeses like Gouda, Edam, and Cheddar, this system excels in handling the complexities of pressing, de-moulding, and brining. The fully automated, PLC-controlled operation ensures consistent high-quality cheese by employing individual pneumatic cylinders for uniform pressing force. It integrates seamlessly into production lines with features such as dual-level cleaning tunnels and mould storage units, enhancing flexibility and hygiene. With a capacity of up to 100 tonnes per day, it optimizes uptime through efficient CIP (clean-in-place) processes, making it an ideal choice for continuous cheese production.

Benefits

- Ensures uniform cheese quality with individual pressing mechanisms for consistent results.

- Increases production flexibility by accommodating various cheese shapes and sizes.

- Enhances operational efficiency with fully automated, PLC-controlled processes.

- Reduces water consumption through a dual-level cleaning tunnel with water recycling capability.

- Maintains a hygienic production environment, minimizing contamination risks.

- Applications

- Hard cheese, Semi-hard cheese

- End products

- Edam, Havarti, Maasdam, Cheddar, Emmental, Gruyère, Gouda, Manchego

- Steps before

- Draining, Forming, Curd preparation

- Steps after

- De-moulding, Brining

- Input ingredients

- curd blocks, mould, lids

- Output ingredients

- pressed cheese, semi-hard cheese, hard cheese, uniform rind cheese

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- Up to 100 tonnes/day

- Automation

- PLC-controlled

- Cleaning method

- CIP

- Pressing force

- Gradually increasing

- Automation level

- Fully automated and PLC controlled

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Enclosed CIP for presses

- Cleaning method

- CIP for enclosed presses

- Cleaning method

- Dual-level cleaning tunnel

- Changeover time

- Shorter cleaning cycles for maximum uptime

- Cheese Type

- Semi-hard and hard cheeses

- Machine footprint

- Compact

- Mould format compatibility

- Multiple types

- Mould storage unit

- Multi-level storage

- Control panel type

- PLC-controlled

- Discharge method

- Automated de-moulding line

- Control panel type

- PLC-controlled

- Mould format flexibility

- Multiple mould formats

- Automation level

- Fully automated