Oven for high-yield cooking of prepared foods

Achieve unparalleled consistency and enhanced yield in food production with an advanced oven solution that offers precise climate control and uniform heat distribution, ensuring top-quality results every time.

Optimizes Yield and Ensures Product Consistency

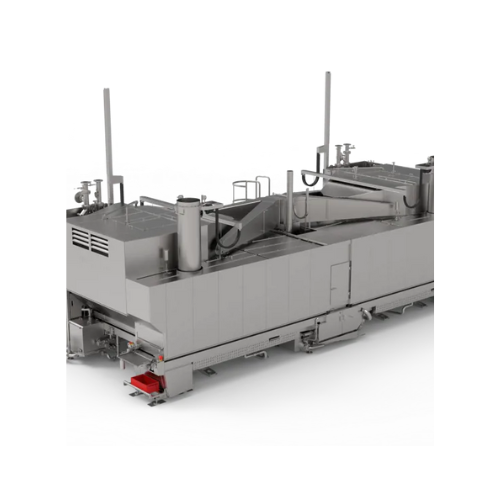

The ModularOven from Marel Prepared Foods sets the standard for precision and efficiency in food processing. This state-of-the-art oven is designed with dual independent zones, allowing for tailored climates that ensure optimal heat distribution and consistent moisture content. Ideal for applications ranging from ready-to-eat meals to plant-based and meat products, it significantly enhances yield by up to 6%. With its spiral belt design, the oven efficiently maximizes processing capacity within minimal floor space, handling high throughput demands. Integrated with Innova software, users benefit from seamless monitoring and control of temperature and moisture levels, complementing the oven’s advanced air regulation system for consistent batch-to-batch results. Experience reduced downtime with its unrivaled remote support, decreasing production interruptions. Built for reliability, the ModularOven utilizes premium materials suited for the rigors of continuous high-speed operations, making it a crucial asset for processors seeking robust and scalable solutions.

Benefits

- Increases yield by up to 6%, enhancing overall productivity and profitability.

- Ensures consistent product quality with precise moisture and temperature control.

- Integrates easily into production lines with remote support, minimizing downtime.

- Reduces operating costs with energy-efficient air regulation.

- Supports diverse applications, from plant-based to traditional meat products, boosting versatility.

- Applications

- Meat products, Fish products, Pet food, Convenience products, Cheese, Poultry products, Plant-based products, Fruit and vegetables, Sausages, Potato specialties

- End products

- Chicken nuggets, Salmon fillets, Breakfast sausages, Canned pet food, Fried potato wedges, Packed mixed vegetables, Beef patties, Cheese bites, Breaded fish sticks, Kibble, Plant-based nuggets, Vegan sausages, Ready-to-eat meals, French fries

- Steps before

- Preparation, Marinating, Forming, Coating

- Steps after

- Cooling, Packing and labeling, Weighing, Batching

- Input ingredients

- raw food products, food ingredients, meat, poultry, fish, plant-based ingredients

- Output ingredients

- cooked products, fried products, uniformly processed food, high yield food products, consistent batch-to-batch products

- Market info

- Marel is known for its advanced food processing equipment, specializing in systems and services for poultry, meat, and fish industries. It is recognized for innovation, quality, and improving processing efficiency and sustainability.

- Yield

- Up to 6% more than comparable ovens

- Capacity

- Highest capacity on the market

- Belt length

- 163 meters

- Belt surface

- 90 square meters

- Zones

- Two separate zones for independent climates

- Air regulation system

- State-of-the-art, ensures even heat distribution

- Heat transfer

- Even heat transfer across all sides

- Working mechanism

- Spiral belt design

- Integrated steps

- Independent climate zones

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Air regulation system

- Even heat distribution

- Automation level

- PLC

- Energy efficiency

- Up to 6% more yield

- Remote support

- Available

- Belt design

- Spiral

- Zone control

- Independent