Making Halloumi

Find innovative production technology for making halloumi and connect directly with world-leading specialists

Aphrodite’s Rock, the Limassol Carnival, and the Tomb of the Kings are defining features of Cyprus. But perhaps nothing characterizes the Mediterranean island as well as halloumi. The salty, springy cheese has been a staple of Cypriot homes for centuries. But halloumi production technology is now bringing this delicacy to others far away from the region.

Tell us about your production challenge

Wait for the milk temperature to reach 35°C before adding rennet

The traditional Cypriot base for halloumi is sheep or goat milk; the island didn’t have a large population of cows. Producers pasteurize the milk and standardize it using rennet taken from the ruminants’ stomachs.

The enzymes pluck out the bristle-like edges of casein molecules, causing them to clot and the milk to coagulate. Rennet performs better at temperatures around 35°C.

Remove whey protein by blending in 10% milk

Whey is a crucial ingredient in halloumi production. When the milk pasteurized milk clots, cut the coagulate into cubes of approximately 1cm and mix them gently in whey while scalding. This process causes the milk to curdle.

Drain the whey and press the curds to reduce moisture. The pieces are now ready to be cooked in whey again, this time deproteinized. The protein content is removed by mixing the whey in 10% milk volume and heating up to about 90°C.

Allow the halloumi to mature in a brine solution

The classic varieties of halloumi are aged or fresh. The latter style is garnished with dried mint and salt. Fold the cheese pieces after the second cooking process, and add the aromatic mixture between the halves.

The halloumi is ready for consumption. But unless eaten immediately, it is matured in a brine made from salted whey, typically comprising 10-12% sodium chloride.

Combine kinds of milk to develop new palates

A defining characteristic of halloumi is the squeaky sound it makes when you bite into it. This is caused by the long protein strands developed by the rennet.

Halloumi is a soft-ripened cheese, but the texture changes depending on the milk used. Sheep milk produces a harder consistency than goat milk and develops a more distinct yellow color. Some manufacturers blend in bovine milk to make the final product more palatable.

Processing steps involved in halloumi making

Which halloumi technology do you need?

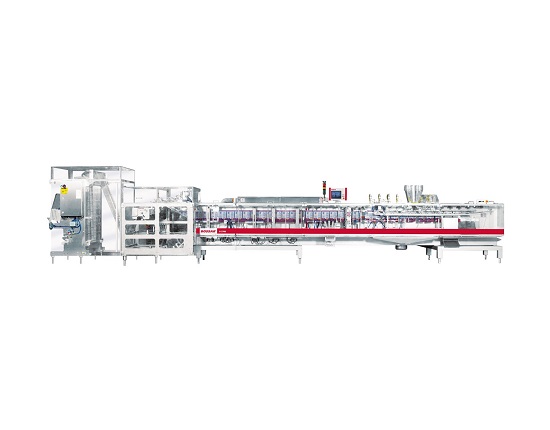

Industrial cheese processing plants

Streamline your cheese production with custom-engineered systems designed to enhance ef...

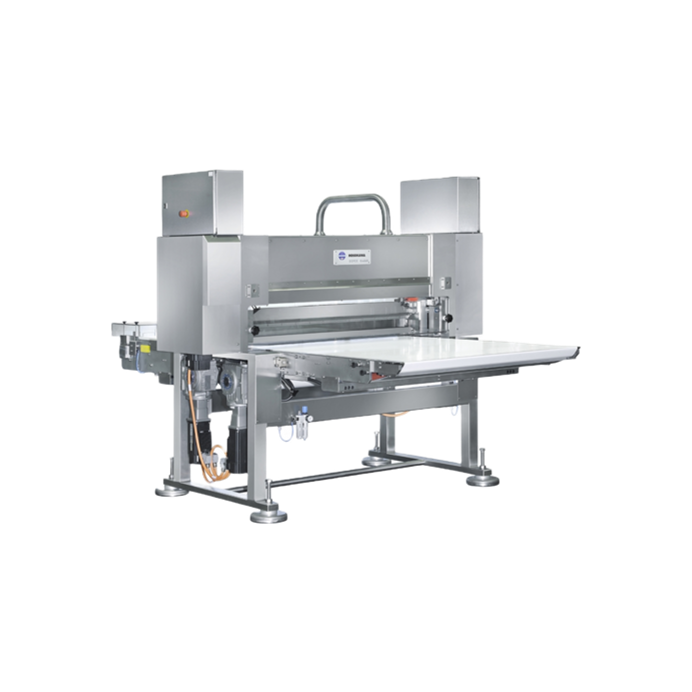

Steam cooker and stretcher for cheese processing

Optimize your cheese production with a versatile solution designed to eff...

Cheese vat for various cheese types production

Optimize curd formation and whey separation for diverse cheese types with a...

Curd making vat for cheese production

Achieve optimal curd consistency and maximize cheese yield with advanced dual agitato...

Food crates washer

With the increasing demand of food production sectors for cutting costs, while increasing quality of produ...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Dairy Packaging Machine

The use of sachets and pouches for powdered or shredded dairy products is an increasingly popular for...

Industrial tilting pan with cooling system

Raw materials need to be processed into finished, cooked products most quickly ...