Versatile plate forming system for food products

Optimize your food production line with a system that forms everything from beef patties to vegan nuggets into precise shapes, ensuring consistent quality, reduced waste, and high-speed efficiency.

Forms and Shapes Diverse Solid Food Products

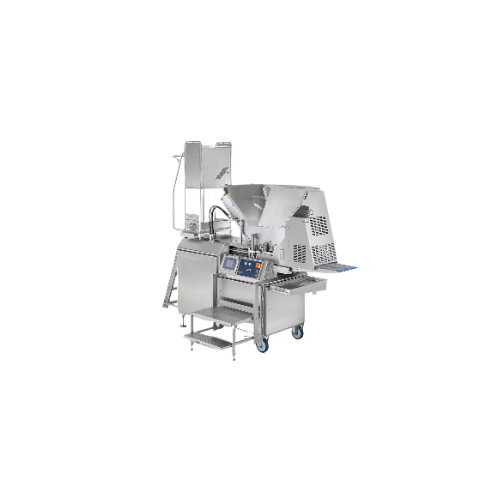

The GEA MultiFormer, engineered by GEA, is a versatile plate forming machine designed to address the diverse needs of food processing companies. This equipment excels in forming and shaping solid foods into various sizes and configurations including beef patties, plant-based burger patties, and shrimp cakes. The MultiFormer operates on a continuous, high-speed basis, utilizing air and water to precisely form products while minimizing waste. With interchangeable form plates and a gentle step-feeding system, it maintains product structure and quality even with delicate muscle products.

Capable of handling 60 to 75 strokes per minute, depending on the model, the machine ensures high-output production. The PLC-controlled system allows for seamless integration into existing production lines, offering options for paper interleavers and stick inserters to enhance product functionality. Energy consumption is minimized with optimized motor functions, and the equipment is available with options like the GEA BridgeBreaker to improve product flow.

Built from stainless steel for superior hygiene, the MultiFormer supports CIP cleaning for efficient maintenance. Its adaptability, coupled with GEA’s engineering support, makes it an ideal choice for food processors seeking to enhance their product offerings across various domains such as meat processing, plant-based foods, and seafood.

Benefits

- Maximizes production flexibility with quick and easy form plate changes.

- Enhances product quality with consistent portion control and structure retention.

- Reduces operational costs through low maintenance and energy-efficient design.

- Supports diverse product ranges with adaptable forming capabilities for various food items.

- Ensures high uptime with proven reliability and minimal changeover time.

- Applications

- Seafood, Potato, Pork, Cheese, Vegan products, Plant-based products, Vegetables, Poultry, Red meat, Fish

- End products

- Chicken nuggets, Cheese slices, Beef patties, Plant-based burger patties, Pork sausages, Vegan nuggets, Vegetable patties, Potato croquettes, Fish fillets, Shrimp cakes

- Steps before

- Grinding, Mixing, Ingredient Preparation

- Steps after

- Coating, Battering, Frying, Packing

- Input ingredients

- red meat, pork, poultry, fish, seafood, cheese, vegetables, plant-based products, potato

- Output ingredients

- rectangular shapes, round shapes, triangular shapes, irregular shapes, novelty shapes, flat appearance, 3D appearance

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Dimension L x W x H

- 2568 x 3140 x 914 mm

- Belt width

- 400 mm

- Max. capacity

- 60 strokes/min

- Max. filling (volume/stroke)

- 1.1 liter

- Electric power

- 8 kW

- Air consumption

- 300 nl/min / cft/min

- Machine weight

- 1200 kg

- Hopper volume

- 270 liter

- Automation

- PLC-controlled

- Material

- Stainless steel

- Water usage reduction

- Up to 80%

- Working mechanism

- Air and water forming system

- Integrated steps

- Programmable PLC for forming cycles

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Changeover time

- Quick plate changeover

- Cleaning method

- Easy to clean stainless steel

- Cleanability

- Stainless steel construction for hygienic design

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Biological compatibility

- Food-grade materials

- Heat sensitivity

- Formable under various temperatures

- Product formability

- Various shapes

- Material diversity

- Red meat, poultry, fish, vegetables, plant-based

- Machine footprint (L x W x H)

- 2568 x 3140 x 914 mm

- 2579 x 2881 x 1652 mm

- 2579 x 3003 x 2000 mm

- Belt Width

- 400 mm

- 600 mm

- 900 mm

- Machine weight

- 1200 kg

- 1820 kg

- 2440 kg

- Hopper volume

- 270 liter

- 380 liter

- 530 liter

- Discharge method

- Step filling principle

- Material

- Stainless steel

- Knock-Out System

- E-knockout and Varioseal

- Forming Plate Material

- PE, PremiumForm

- Forming Plate Shapes

- Rectangular, Round, Triangular, Irregular

- Interchangeable Plates

- Yes, quick changeover

- Knockout System

- GEA E-knockout, Varioseal

- Stick Inserter

- Available

- Tray Transverse Conveyor

- Available

- Ball Rolling Unit

- Available for 400 and 600 mm lines

- Auger Product Feeding

- Step Filling Principle

- Process Recipes

- Stored Process Parameters