Efficient brining system for cheese production

Ensure precise temperature control and consistent quality in your cheese production with an advanced system designed for optimal brining, rapid cooling, and enhanced traceability.

Brines and Cools Cheese Efficiently

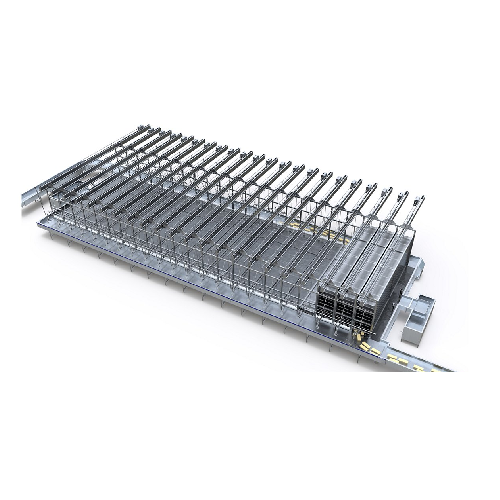

The Tetra Pak® Brining System S is a robust solution tailored for cheese manufacturers, specifically engineered to enhance brining efficiency. This system integrates a continuous brine circulation and cooling process to ensure uniform salt uptake and temperature reduction for varied cheese types, such as mozzarella, provolone, and Swiss cheese. With a design that supports automated, continuous operations, it offers seamless integration into existing processing lines. The equipment features a precise salt monitoring system and perforated cages for optimal brine exposure, eliminating the need for frequent brine replacement.

The system supports a wide range of cheese formats, including blocks, wheels, and specialties, addressing flexibility in production. Its adaptable layout can be customized to fit specific plant configurations, ensuring maximum usage of floor space. Constructed for durability, the Tetra Pak® Brining System S employs high-grade materials suited for rigorous food production environments, and its continuous cleaning capabilities reduce maintenance downtime. Designed with traceability in mind, it captures cheese data throughout the brining process to facilitate quality assurance and compliance, aligning with industry standards for food safety and processing efficiency.

Benefits

- Enhances product quality with consistent salt absorption and temperature control.

- Optimizes space utilization by integrating the brine tank into the production floor.

- Minimizes maintenance with automated cleaning and continuous brine filtering.

- Supports a variety of cheese formats to meet diverse production needs.

- Improves traceability and quality control through precise data tracking.

- Applications

- Cheese specialties, Mozzarella cheese, Swiss cheese, Provolone cheese

- End products

- Cheese wheels, Cheese cubes, Cheese rolls, Sliced cheese, Pizza cheese, Table cheese, Cheese blocks

- Steps before

- Curd formation, Cheese molding, Draining

- Steps after

- Aging, Packaging, Distribution

- Input ingredients

- cheese blocks, Euro blocks, provolone, 2.5kg cheese blocks, 6 lb. cheese blocks, 20 lb. cheese blocks, cheese wheels, big block Swiss, specialty cheeses

- Output ingredients

- brined cheese, submerged cheese blocks, cooled cheese, Mozzarella cheese

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- Per customer specifications

- Block size flexibility

- Euroblock (500x300 mm), provolone (varies), 2.5kg (90mmx90mmx271mm), 6 lb.(4in X 4in x 11in), 20 lb. (3.75in x 7in x 21in)

- Cooling temperature

- Reaches core temperature faster

- Brine circulation

- Continuous cleaning

- Brine turnover rate

- High

- Automation

- Automated brine maker

- Brine circulation system

- Continuous flow

- Cooling system

- Efficient, reaches core temperature faster

- Brine time

- Reduced time for maximum salt absorption

- Floor space utilization

- Optimal as brine tank goes into the floor

- Traceability

- Maintains vat identity throughout the process

- Automation level

- Automated brine maker for precise salt levels

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Optimal use of floor space, as brine tank goes into the floor

- Tank shape and size

- Designed for a variety of cheese sizes including Euro blocks, wheels, and big block Swiss

- Brine circulation system

- Perforated cages ensure maximum circulation

- Block size flexibility

- Handles variety of cheese sizes including 2.5kg, 6 lb., 20 lb.

- Adaptable layout

- Tailored to fit available plant space

- Control panel type

- PLC-controlled

- Layout adaptability

- Customizable to plant space

- Block size flexibility

- Handles multiple cheese sizes

- Integration possibilities

- Compatible with existing production lines

- Traceability

- Enhanced quality control