Processed cheese slice wrapper

Effortlessly wrap individually-portioned cheese slices with precision and uniformity, ensuring secure packaging and easy handling without risking recontamination. Maximize production speed while minimizing material usage, enhancing operational efficiency in your food processing line.

Wraps and Portions Cheese Slices Continuously

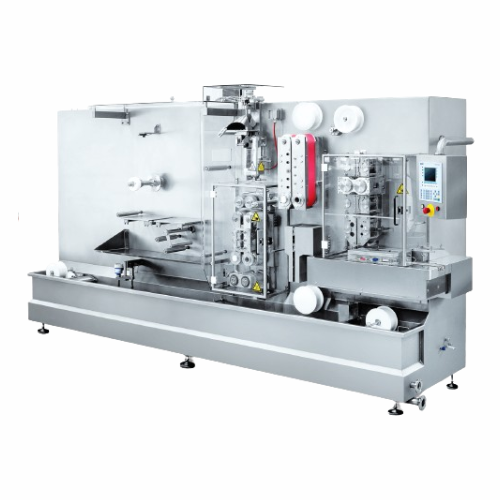

The FreePack 500 from the Natec Network is a cutting-edge cheese slice wrapping machine designed for streamlined and efficient packaging solutions in food processing. Utilizing a continuous operation hot-fill system, it ensures hygienic wrapping of individually-wrapped cheese slices without the risk of recontamination. Notably, the machine reduces plastic foil usage by 20% with its precise welding seams, thereby minimizing material waste. Ideal for processed cheese applications, the FreePack 500 delivers a throughput of up to 500 slices per minute, accommodating various slice weights from 13 to 42 grams. This high-speed solution is perfect for ready-to-eat cheese snacks and convenience foods, offering easy integration into existing production lines with its comprehensive automation capabilities, including a central control system for seamless operation. Optional features such as inkjet printing and semi-automatic film splicing further enhance its flexibility. The machine’s robust construction adheres to CE guidelines, ensuring durability and safety in demanding production environments.

Benefits

- Enhances production efficiency by wrapping up to 500 cheese slices per minute.

- Reduces material costs with 20% less plastic foil usage due to precise sealing.

- Ensures product integrity with hygienic, contact-free sealing method.

- Offers versatile packaging options with customizable slice weights and formats.

- Facilitates easy operation and minimal downtime with a centralized control system.

- Applications

- Convenience foods, Cheese slices, Processed cheese, Food packaging, Food processing, Cheese production, Ready-to-eat cheese, Dairy products

- End products

- Single-serve cheese portions, Individually-wrapped processed cheese slices, Pre-portioned cheese packs, Ready-to-eat cheese snacks, Convenient cheese slice packages

- Steps before

- Emulsification, Blending, Cooking, Pasteurising, Ultra high temperature processing

- Steps after

- Stacking, Flowpacking, Cooling, Packing

- Input ingredients

- processed cheese, cheese solids, PP foil, compressed air, fresh water, cooling water

- Output ingredients

- individually-wrapped processed cheese slices, plastic foil reduction, exact piles of cheese slices

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Machine dimensions

- 4, 200 x 1, 100 x 2, 200 mm (165" x 40" x 84")

- Power supply

- 400 V, 50 Hz, 3 phase / 15 kVA

- Capacity

- Max 500 slices/min = 600 kg/h (1, 300 lbs/h)

- Compressed air

- 3 m³/h at 6 bar

- Cooling capacity

- 30 kW / 170, 700 BTU/h

- Operating temperature of cooling water

- Approx. 3 °C (37 °F)

- Slice weight range

- Infinitely adjustable from 13 g - 30 g

- Slice thickness range

- 1.5 to 3.5 mm (0.06"-0.14")

- Slice dimensions

- 84x84 mm (3.3" x 3.3")

- Max stacking height

- 75mm (3")

- Processable cheese solids - Water content

- 40 %-56 %

- Processable cheese solids - Dry matter

- 44 % - 60 % with 45 % fat content

- Working mechanism

- Continuously operating production method

- Automation level

- Central control surveillance system

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Contact-free sealing eliminates need for wear and tear

- Biological compatibility

- Food-grade

- Cleanability

- Easy to clean, hygienic design

- Corrosive resistance (e.g. acids)

- High resistance, stainless steel construction

- Density/particle size

- Applicable to cheese pieces

- Abrasion resistance

- Durable against wrapping materials

- Cheese consistency

- Semi-hard / Soft / Processed

- Foil type

- PP foil / Recyclable

- Slice weight range

- 13 g to 30 g (adjustable)

- Slice thickness range

- 1.5 mm to 3.5 mm

- Package stacking height

- Up to 75 mm

- Processable cheese solids

- Water content 40%–56%

- Cheese fat content

- 45%

- Hygienic sealing

- Contact-free

- Machine footprint

- 4, 200 x 1, 100 x 2, 200 mm

- Slice weight range

- 13 g - 42 g

- Slice format

- 84 x 84 mm

- Slice thickness

- 1.5 to 3.5 mm

- Max. stacking height

- 75 mm

- Discharge method

- Contact-free sealing

- Control panel type

- Central control surveillance system

- Integration possibilities

- Inkjet printer, cooling options

- Customization option

- Inkjet printer for marking ("open here")

- Customization option

- Cooling with ice water or glycol

- Customization option

- Semi automatic film splicing