Inspection system for detecting film shreds and mould on cheese blocks

Ensure flawless cheese quality by detecting hidden film residues and mould with precision in your production line.

Detects Mould and Film Residues

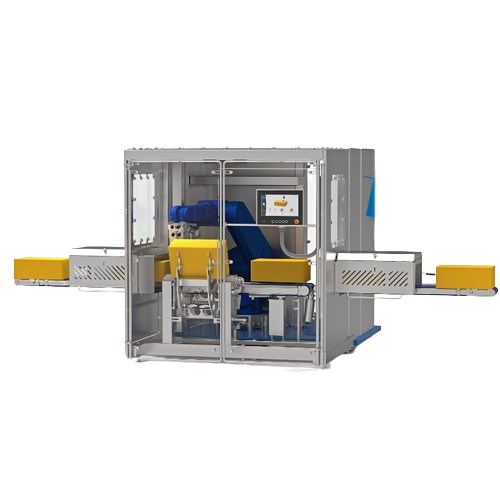

The Eagle Eye 2 from ALPMA Alpenland Maschinenbau GmbH is an advanced inspection system designed specifically for cheese and dairy producers. What sets this system apart is its ability to detect even transparent film residues and mould on cheese blocks with a hit rate greater than 99%, ensuring unparalleled quality assurance.

The system works by automatically transporting cheese blocks through a multi-station scanning process. It begins by scanning five sides of the block before tilting it for bottom inspection, seamlessly integrating into fully automated production lines.

Capable of processing a variety of cheese types, including Cheddar and Euro blocks, at a rate of up to 5 blocks per minute, the Eagle Eye 2 offers high-speed, continuous operation tailored for demanding production environments. Its sleek PLC-controlled design allows for effective integration into existing manufacturing systems, enhancing overall efficiency without compromising quality.

Constructed to withstand the rigors of food processing, the Eagle Eye 2 aligns with industry standards and offers ease of maintenance. This crucial inspection tool is vital for production facilities prioritizing superior product quality and operational efficiency.

Benefits

- Ensures consistent product quality with over 99% accuracy in detecting mould and film residues.

- Enhances production efficiency by integrating seamlessly into existing automated lines.

- Minimizes manual inspection time, reducing labor costs and human error.

- Adapts to various cheese block sizes, supporting production flexibility.

- Contributes to overall operational efficiency with high-speed processing up to 5 blocks per minute.

- Applications

- Snacks, Dairy products, Cheese, Processed cheese

- End products

- Cheddar cheese blocks, Euro cheese blocks, Transparent film-free cheese blocks

- Steps before

- Raw Material Automation, Pre-Cutting, Cheese Block Formation, Cheese Block Transportation

- Steps after

- Quality Assurance, Packing, Shipping, Product Labeling

- Input ingredients

- cheese blocks, euro block, cheddar block

- Output ingredients

- inspected cheese blocks, mould-free cheese blocks, film-free cheese blocks

- Market info

- ALPMA Alpenland Maschinenbau is known for specializing in manufacturing cutting-edge machinery and processing equipment for the cheese and dairy industry, holding a strong reputation for innovation, quality, and highly engineered-to-order solutions globally.

- Speed

- max. 5 blocks/min

- Format Range - Euro Block

- 500 x 300 x 100 mm

- Format Range - Cheddar Block

- 360 x 280 x 180 mm

- Inspection Hit Rate

- > 99%

- Automation Level

- Fully Automated

- Working mechanism

- Automatic scanning and detection

- Integrated steps

- Multi-side surface scanning and bottom scan

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous

- Hit detection rate

- > 99%

- Film and mould detection

- Yes, including transparent films

- Product Type

- Cheese blocks

- Integration possibilities

- Fully automated production line integration